Neodymium-ytterbium codoped lanthanum fluoride upconversion phosphor powder and preparation method thereof

A technology of co-doping and lanthanum fluoride, applied in the field of phosphors, achieves the effects of low energy consumption, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

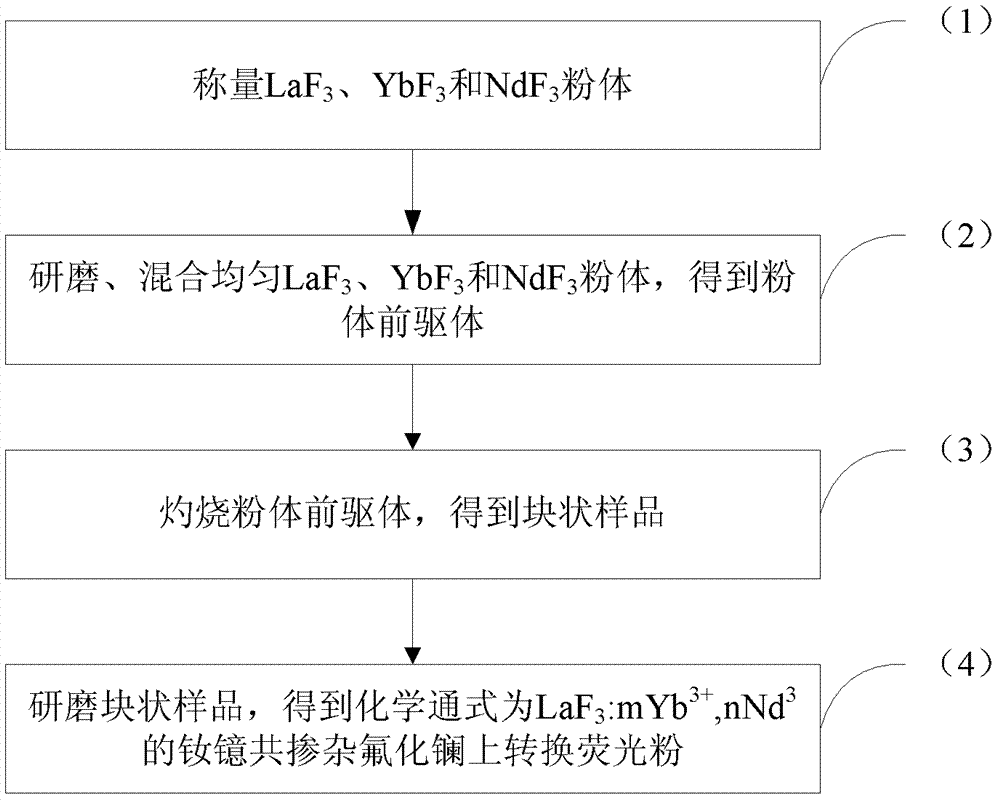

[0021] The preparation method of the above-mentioned neodymium ytterbium co-doped lanthanum fluoride up-conversion phosphor, such as figure 1 shown, including the following steps:

[0022] (1) Weigh LaF with a purity of 99.99% 3 , YbF 3 and NdF 3 The powder has a molar ratio of (92-99.3):(0.5-5):(0.2-3), preferably 96:3:1.

[0023] (2) Grind the powder in step (1) in a corundum mortar for 20 to 60 minutes, preferably 40 minutes, to obtain a uniform powder precursor, that is, a uniformly mixed LaF 3 , YbF 3 and NdF 3 Powder;

[0024] (3) Put the powder precursor in step (2) into a muffle furnace and burn at 800-1000°C (preferably 950°C) for 0.5-5 hours, preferably 3 hours; obtain a block sample

[0025] (4) Lower the temperature of the block sample to 250°C for 2 hours, then cool to room temperature with the furnace to obtain the target block product; take it out and grind it to obtain the general chemical formula LaF 3 :mYb 3+ , nNd 3+ Neodymium-ytterbium co-doped la...

Embodiment 1

[0030] Choose powder with a purity of 99.99%, LaF 3 , YbF 3 and NdF 3 Powder, the molar ratio is 96:3:1 (ie, the molar numbers are 0.96mmol, 0.03mmol, 0.01mmol respectively). Grind in a corundum mortar for 40 minutes to make it evenly mixed, and then burn it in a muffle furnace at 950°C for 3 hours to obtain a uniformly mixed powder precursor, and then place the powder precursor at a temperature of 900°C After burning for 3 hours, a lumpy sample was obtained. Then the block sample was cooled to 250°C for 2 hours, and then naturally cooled to room temperature to take out the block product and crush it to obtain LaF 3 :0.03Yb 3+ , 0.01Nd 3+ Up-conversion phosphors; among them, LaF 3 as matrix, Yb 3+ and Nd 3+ is the luminescent central ion.

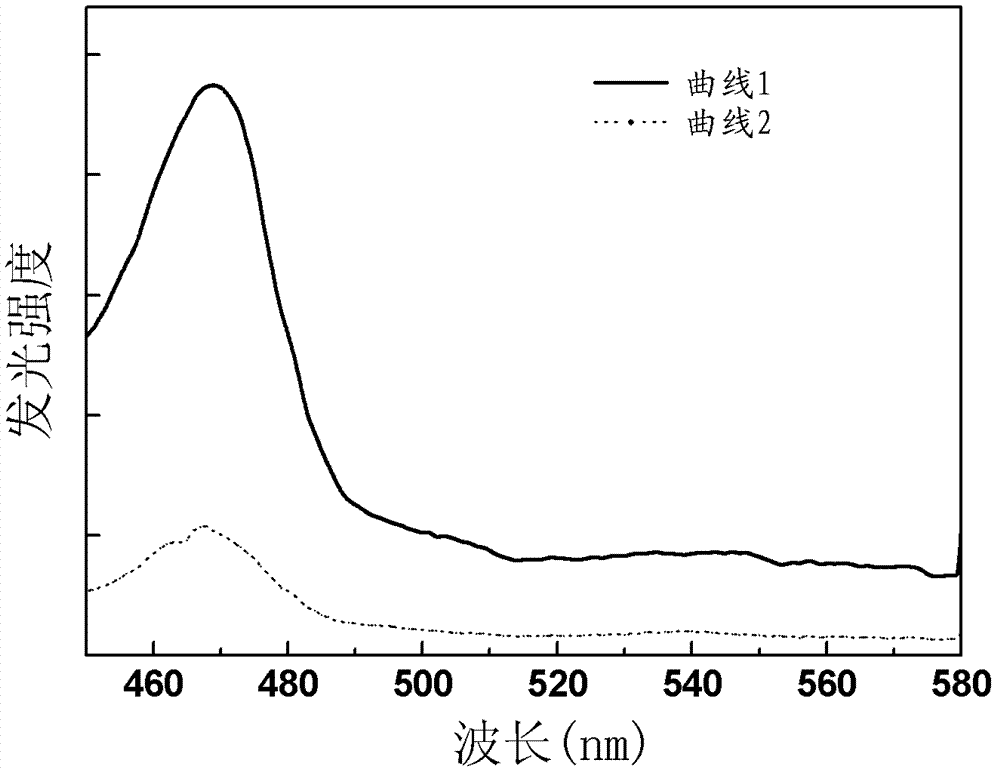

[0031] figure 2 For the neodymium ytterbium co-doped lanthanum fluoride up-conversion phosphor powder and comparative example that are made in embodiment 1, namely undoped ytterbium lanthanum fluoride up-conversion phosphor powde...

Embodiment 2

[0034] Choose powder with a purity of 99.99%, LaF 3 , YbF 3 and NdF 3Powder, the molar ratio is 99.3:5:3 (ie, the molar numbers are 0.965mmol, 0.005mmol, 0.03mmol respectively). Grind in a corundum mortar for 20 minutes to make it evenly mixed, and then burn it in a muffle furnace obtained at 800°C for 3 hours to obtain a uniformly mixed powder precursor, and then place the powder precursor at a temperature of 800°C Burn for 5 hours to obtain a lumpy sample. Then the block sample was cooled to 250°C for 2 hours, and then naturally cooled to room temperature to take out the block product and crush it to obtain LaF 3 :0.005Yb 3+ , 0.03Nd 3+ Up-conversion phosphors; among them, LaF 3 as matrix, Yb 3+ and Nd 3+ is the luminescent central ion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com