Preparation method of apple vinegar

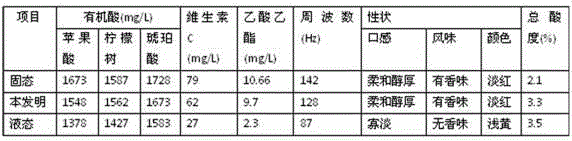

An apple cider vinegar and apple technology, applied in the field of food processing, can solve the problems of poor liquid fermentation quality and long solid state fermentation period, and achieve the effects of long residence time, shortened brewing period and reduced fermentation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of apple cider vinegar, comprising the following steps:

[0028] (1) Wash and crush the apples, control the sugar content at 10-12%, and then energize and magnetize to obtain magnetized apple juice;

[0029] (2) Add 0.025% yeast and 1.5% alcohol to the magnetized apple juice, keep the temperature at 33-37°C, and ferment for 3 days to obtain apple wine;

[0030] (3) Add acetic acid bacteria with 0.1% of the mass of apple juice in the apple wine, keep the temperature at 23-27°C, and ferment for 2.5 days to obtain apple cider vinegar;

[0031] (4) Drenching and sterilizing the apple cider vinegar, then adding 0.01% of the mass of apple cider vinegar with methylglyoxal, aging for 12 days, adjusting the acidity to 3.5-4%, and the finished product is obtained.

Embodiment 2

[0033] A preparation method of apple cider vinegar, comprising the following steps:

[0034] (1) Wash and crush the apples, control the sugar content at 10-12%, and then energize and magnetize to obtain magnetized apple juice;

[0035] (2) Add 0.02% yeast and 0.5% alcohol to the magnetized apple juice, keep the temperature at 33-37°C, and ferment for 2.5 days to obtain apple wine;

[0036] (3) Add acetic acid bacteria with 0.1% of the mass of apple juice in the apple wine, keep the temperature at 23-27°C, and ferment for 2 days to obtain apple cider vinegar;

[0037] (4) Drenching and sterilizing the apple cider vinegar, then adding 0.01% of the mass of apple cider vinegar with methylglyoxal, aging for 11 days, adjusting the acidity to 3.5-4%, and the finished product is obtained.

Embodiment 3

[0039] A preparation method of apple cider vinegar, comprising the following steps:

[0040] (1) Wash and crush the apples, control the sugar content at 10-12%, and then put the crushed apple juice in a magnetization machine for magnetization to obtain magnetized apple juice;

[0041] (2) Add 0.015% yeast and 1% alcohol to the magnetized apple juice, keep the temperature at 33-37°C, and ferment for 2 days to obtain apple wine;

[0042] (3) Add acetic acid bacteria with 0.1% of the mass of apple juice in the apple wine, keep the temperature at 23-27°C, and ferment for 3 days to obtain apple cider vinegar;

[0043] (4) Drenching and sterilizing the apple cider vinegar, then adding 0.01% of the mass of apple cider vinegar with methylglyoxal, aging for 10 days, adjusting the acidity to 3.5-4%, and the finished product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com