Method for preparing intelligent temperature regulation fiber by melt spinning process

A technology of intelligent temperature regulation and melt spinning, which is applied in rayon manufacturing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of easy degradation or deterioration of phase change materials, loss of energy storage and temperature regulation functions, etc., and achieve high The effect of efficiency and fast response efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

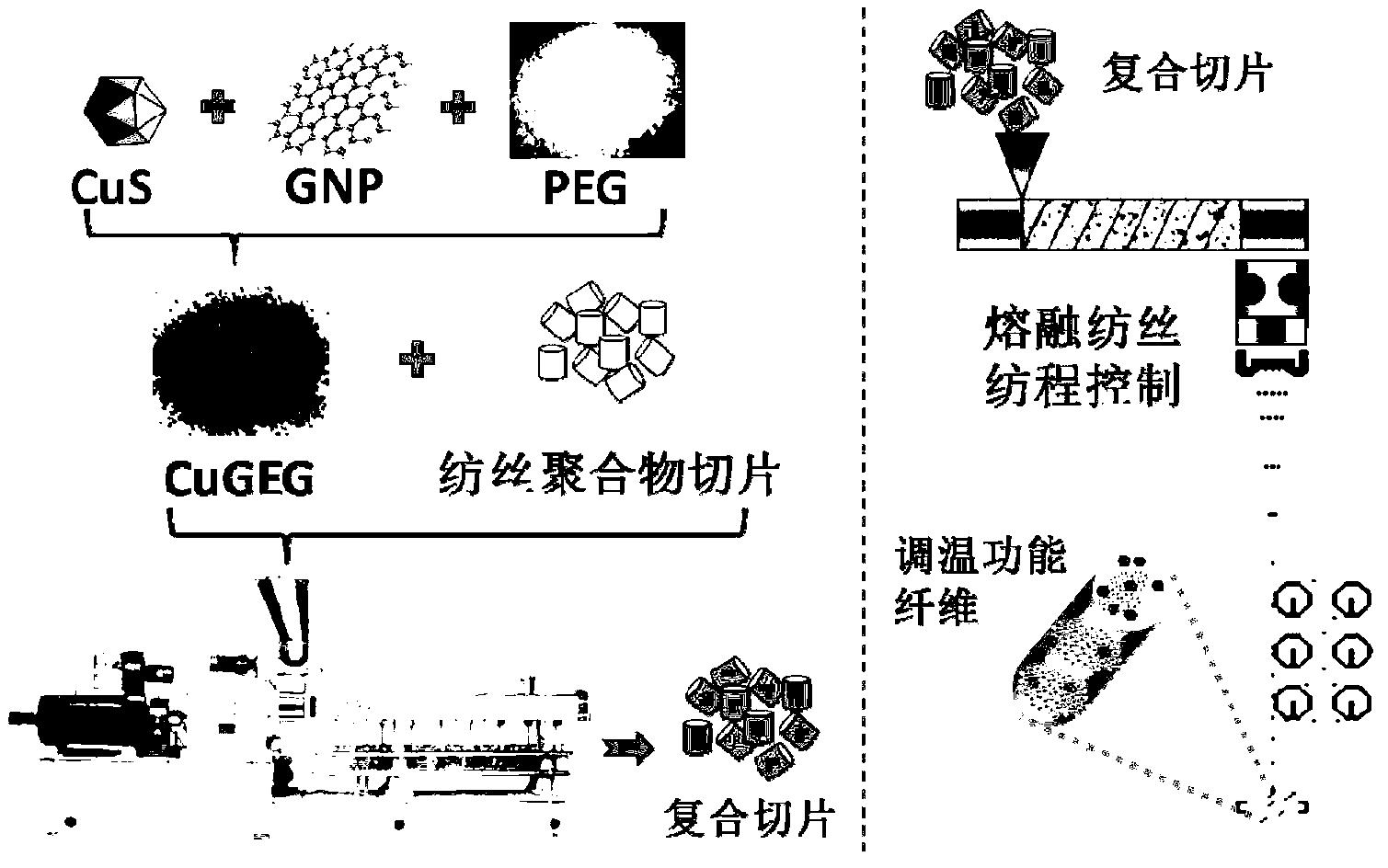

[0025] Firstly, graphene, copper sulfide and polyethylene glycol with a mass ratio of 1:1:1000 were fully blended at 60°C for 2 hours to obtain a ternary composite phase change medium (CuGEG); secondly, a mass ratio of 5 : 95 CuGEG and polypropylene (PP) slices were blended and granulated by twin-screw at 190°C to obtain composite slices; finally, after the composite slices were dried, and the moisture content was controlled at 50-100ppm, the energy storage adjustment was obtained by melt spinning. warm fiber. figure 1 A schematic diagram of the preparation of temperature-regulated fibers is given.

Embodiment 2

[0027] Firstly, graphene, copper sulfide and polyethylene glycol with a mass ratio of 50:50:1000 were fully blended at 80°C for 4 hours to obtain a ternary composite phase change medium (CuGEG); secondly, a mass ratio of 40 : 60 CuGEG and polyethylene terephthalate (PET) slices were mixed and granulated by twin-screw at 280°C to obtain composite slices; finally, after the composite slices were dried, the water content was controlled at 50-100ppm, and melted Spinning to obtain energy storage temperature-regulating fibers.

Embodiment 3

[0029] First, using graphene, copper sulfide and polyethylene glycol acrylate (Mn≈1000) with a mass ratio of 5:5:1000, adding N,N'-methylene glycol acrylate with a mole fraction of 20% Based on bisacrylamide as a crosslinking agent, CuGEG was obtained by solution radical polymerization; secondly, CuGEG and polybutylene terephthalate (PBT) with a mass ratio of 30:70 were granulated by twin-screw blending at 290°C Composite slices are obtained; finally, after the composite slices are dried, and the water content is controlled at 50-100 ppm, the energy storage and temperature-regulating fibers are obtained by melt spinning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com