Acid bleaching and brightening method of fluff fibers

An acid bleaching and fiber technology, used in bleaching products, textiles and papermaking, etc., can solve the problems of serious fiber damage, poor product feel, felting, etc., achieve high detergency and carrying power, and improve vividness and brightness. , Improve the effect of strength and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Raw material: white cashmere loose fiber

[0017] Weight: 100kg

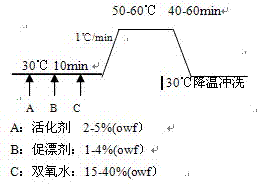

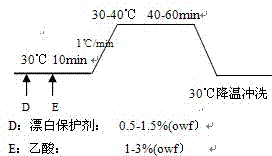

[0018] According to the attached figure 1 Process, add 3% activator at 30°C, add 1% bleach accelerator, 25% hydrogen peroxide, and run for 10 minutes; adjust the pH value to 5.5, raise the temperature at a rate of 1°C / min, rise to 60°C, and keep warm for 50 minutes. Cooling, washing, out of the tank. Add 1% activator at 30°C, add 2% acetic acid, adjust the pH value to 4.2, and run for 10 minutes; heat up at a speed of 1°C / min, rise to 40°C, keep warm for 50 minutes, cool down, and rinse.

[0019] According to the attached figure 2 Process, add 3% no-cleaning agent at room temperature, run for 40 minutes, and rinse.

[0020] Add 2% acetic acid at 30°C according to the attached drawing 3 process in the manual, add 0.8% leveling agent MF, add 2% ammonium sulfate, add 2% no-cleaning agent, and run for 10 minutes; add 0.06% acid red B, run 10 minutes; heat up at a rate of 1°C / min to 90°C a...

Embodiment 2

[0022] Raw material: white cashmere

[0023] Quantity: 50kg

[0024] Bleach:

[0025] According to the attached figure 1 Process, add 4% activator at 30°C, add 2% bleach accelerator, 30% hydrogen peroxide, and run for 10 minutes; adjust the pH value to 6.0, raise the temperature at a rate of 1°C / min, rise to 60°C, and keep warm for 60 minutes. Cool down, rinse. Add 1.5% activator at 30°C, add 1.5% acetic acid, adjust the pH value to 4.0, run for 10 minutes; raise the temperature at 1°C / min to 40°C, keep warm for 60 minutes, cool down, rinse, and leave the tank.

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com