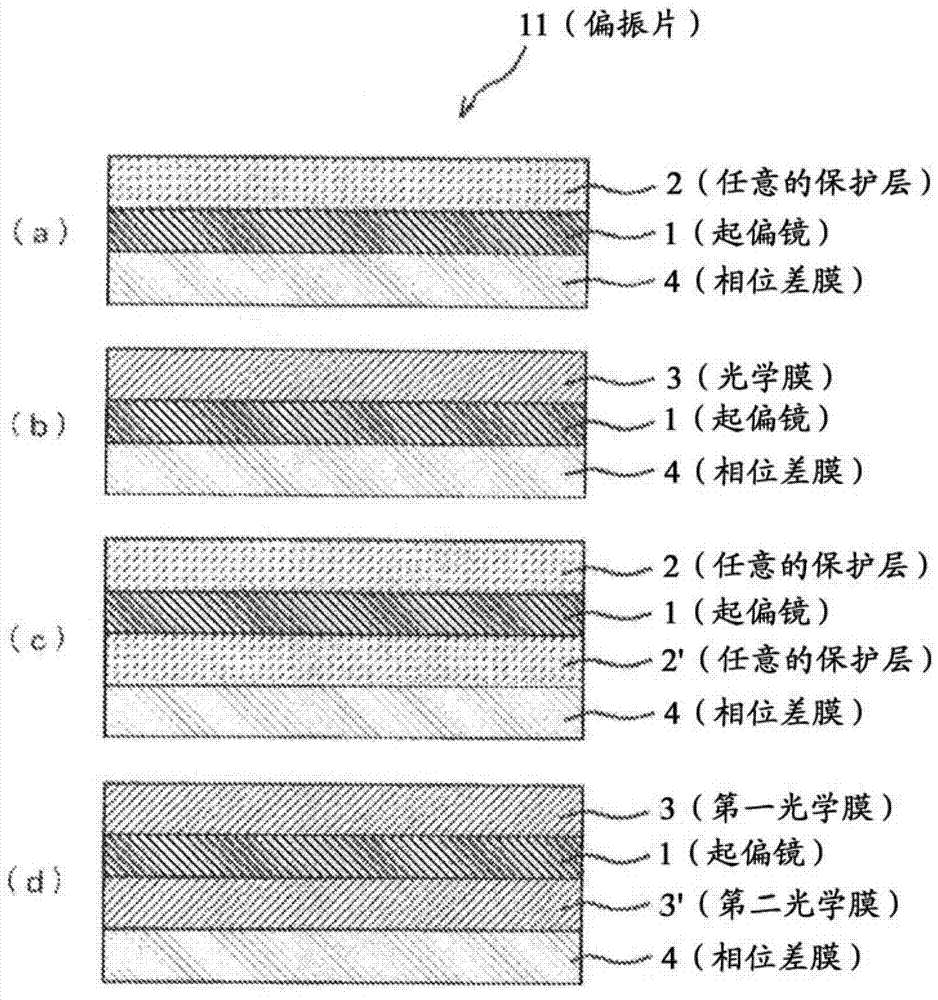

Retardation film, polarizing plate, and display panel device

A technology of retardation film and polarizer, which can be used in polarizing elements, instruments, optical elements, etc., and can solve problems such as improvement of brittleness and film cracking that have not been discussed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

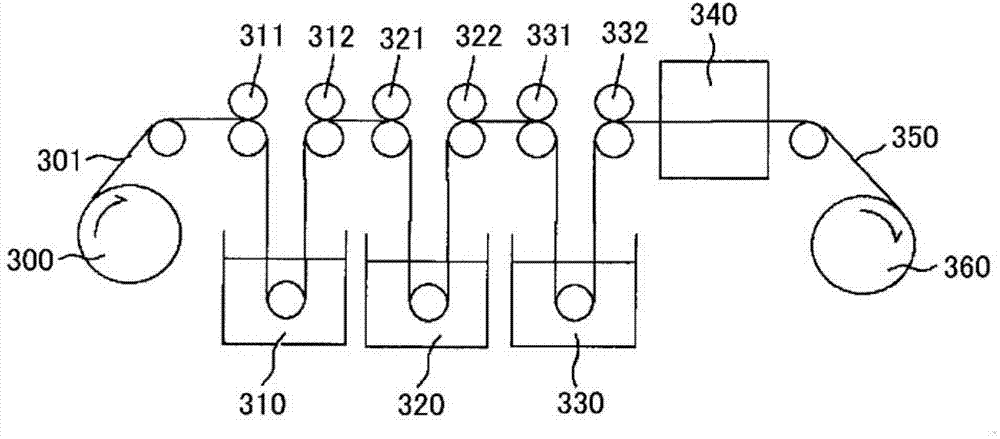

Method used

Image

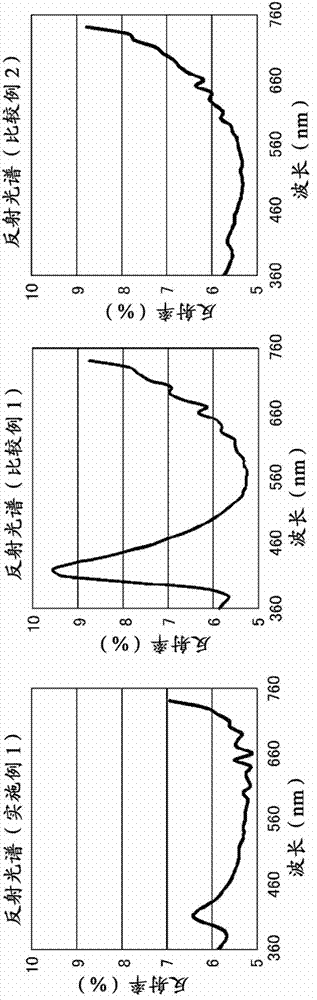

Examples

Embodiment 1

[0152] 8.8 g of polyvinyl alcohol-based resin [manufactured by Nippon Synthetic Chemicals Co., Ltd., trade name "NH-18" (polymerization degree = 1800, saponification degree = 99.0%)] was dried at 105 ° C for 2 hours, and then dissolved in 167.2 g of in dimethyl sulfoxide (DMSO). 2.98 g of 2-methoxy-1-naphthaldehyde and 0.80 g of p-toluenesulfonic acid monohydrate were added thereto, and stirred at 40° C. for 1 hour. 3.18 g of benzaldehyde was added to the reaction solution, stirred at 40° C. for 1 hour, and then 4.57 g of dimethyl acetal was added, and stirred at 40° C. for 3 hours. Then, 2.13 g of triethylamine was added to terminate the reaction. The obtained crude product was reprecipitated with 1 L of methanol. The filtered polymer was dissolved in tetrahydrofuran, and reprecipitated with methanol again. This was filtered and dried to obtain 11.9 g of a white polymer. The polymer is used 1 As a result of H-NMR measurement, it had a repeating unit represented by the fo...

Embodiment 2

[0157] The thickness of the film before stretching was set at 150 μm instead of 135 μm, the stretching temperature was set at 133° C. instead of 135° C., and the stretching ratio was set at 2.2 times instead of 2.1 times. 1 Stretched film (retardation film) A-2 was produced in the same way. Table 1 shows the properties of the obtained retardation film A-2.

Embodiment 3

[0159] The thickness of the film before stretching was set at 130 μm instead of 135 μm, the stretching temperature was set at 130° C. instead of 135° C., and the stretching ratio was set at 2.8 times instead of 2.1 times. 1 Stretched film (retardation film) A-3 was produced in the same way. Table 1 shows the properties of the obtained retardation film A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| drawing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com