Tin ball production method and equipment for semiconductor packaging

A solder ball and equipment technology, applied in the field of solder ball manufacturing and equipment for semiconductor packaging, can solve the problems of high cost of production equipment, uneven thickness of tin wires, affecting the size of solder balls, etc., and achieves convenient operation and high yield. , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

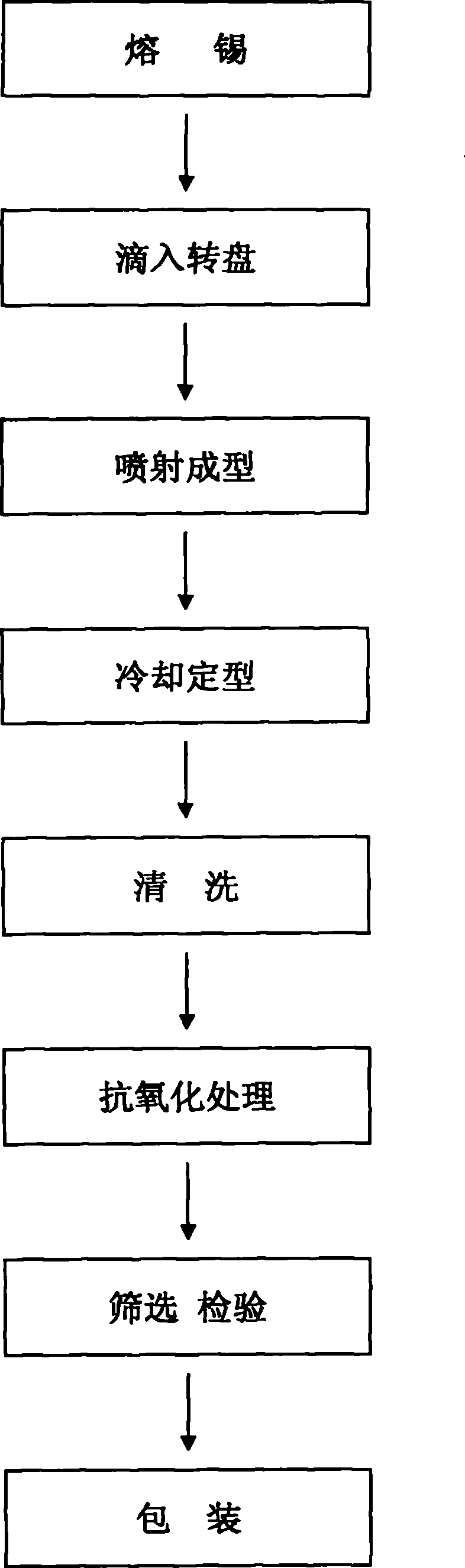

[0024] Such as figure 1 As shown, the production method created by the present invention includes steps such as melting tin, flowing into a turntable, injection molding, cooling and shaping, cleaning, anti-oxidation treatment, screening, inspection, and packaging.

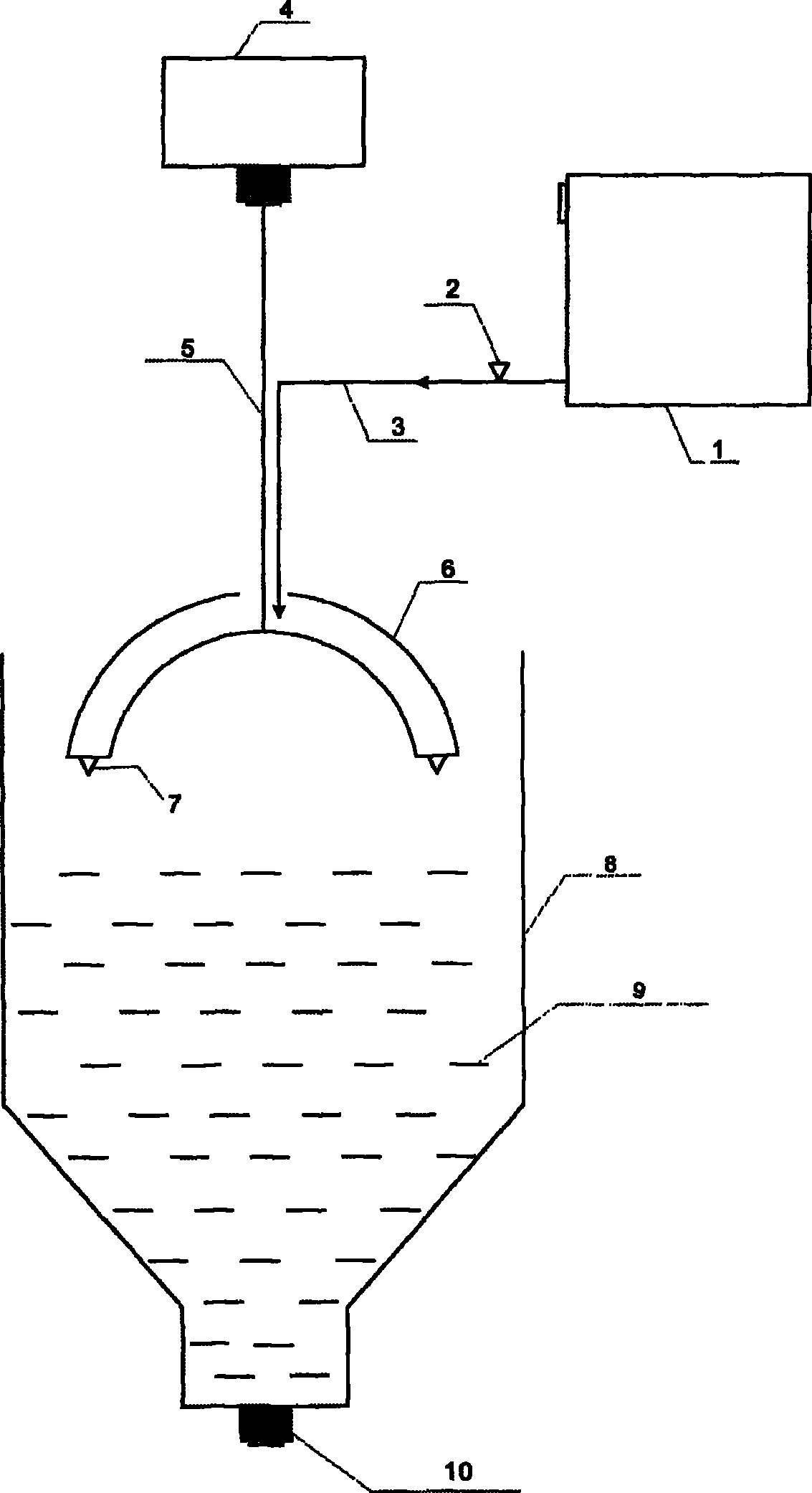

[0025] Such as figure 2 Shown, the equipment that the present invention creates comprises melting furnace 1, pipeline 3, injection molding device, and injection molding device comprises turntable 6, agitator 4, cooling tank 8, coolant 9, and melting furnace 1 is connected to the normal of turntable 6 by pipeline 3 At the top, the tin material is melted in the melting furnace 1 and flows into the turntable 6 through the pipeline. The stirrer 5 is connected to the bottom of the mixer 4. The stirrer 4 is fixed by the inner spherical surface of the stirrer 5 and the turntable 6. The turntable 6 is in the shape of a hemisphere, and a nozzle 7 is installed at the bottom. A cooling tank 8 is provided directly below the ...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 lies in that the arc of the turntable 6 in the above equipment is 150°, the width of the inner cavity is 8 cm, and the radius of the outer ball is 20 cm. When producing lead-free solder balls with a ball diameter of 1.0mm, first put the lead-free tin material alloy into the melting furnace 1 to heat and melt, and make the temperature of the tin liquid reach 450°C, open the flow valve 2 to make the tin liquid flow continuously and evenly The rotation speed reaches 1100 rpm and is preheated to 450°C in the turntable 6, and it is ejected from a nozzle 7 with a diameter of 1.1 mm, and falls into a cooling chamber filled with a cooling liquid 9-polyethylene glycol 800 with a temperature of 50°C. 1.0mm lead-free solder ball in the cooling process, and then taken out through the discharge valve 10 at the bottom of the cooling tank 8, the solder ball is cleaned, anti-oxidation treatment, screening, inspection, and then pack...

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 lies in that the arc of the turntable 6 in the above equipment is 180°, the width of the inner cavity is 10 cm, and the radius of the outer ball is 25 cm. When producing tin-lead alloy tin balls with a ball diameter of 0.1 mm, first put the tin-lead alloy tin ball tin material alloy into the melting furnace 1 to heat and melt, and make the temperature of the tin liquid reach 350°C, and open the flow valve 2 to make the tin liquid continue And evenly flow into the turntable 6 with a rotation speed of 2000 rpm and preheated to 350°C, and spray it out from a nozzle with a diameter of 0.2mm, and fall into the cooling liquid 9-polyethylene glycol with a temperature of 70°C 600 in the cooling tank 8, and during the cooling process, it is shaped into 0.1mm lead-free solder balls, and then taken out through the discharge valve 10 at the bottom of the cooling tank 8, the solder balls are cleaned, anti-oxidation treatment, sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com