Portable miniature energy-storing spot welding machine

A portable spot welding machine technology, applied in energy storage discharge welding, welding power supply, welding equipment, etc., can solve the problems of inaccurate current regulation, low power consumption efficiency, and bulky equipment, so as to improve energy utilization and reduce power supply Voltage, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. However, the examples given are not intended to limit the present invention.

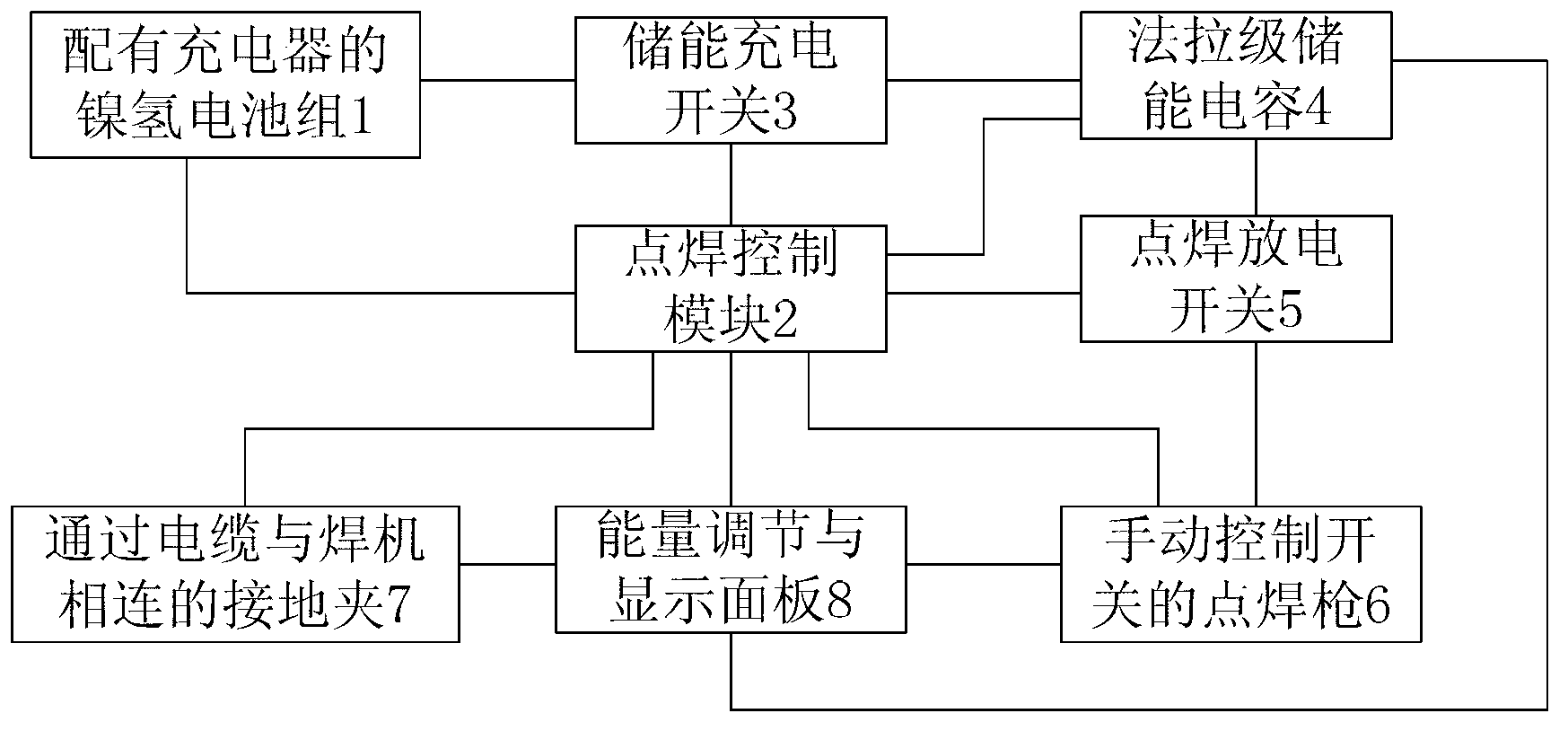

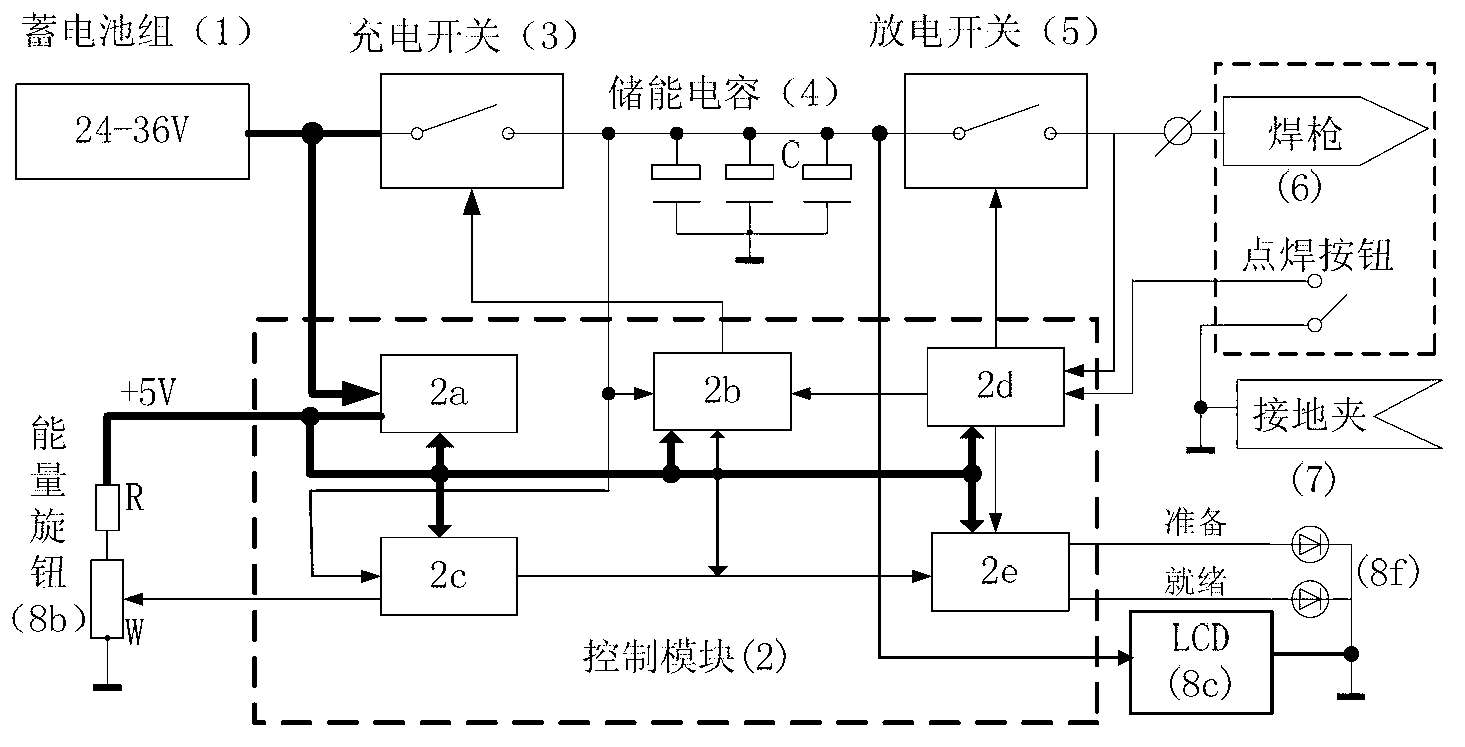

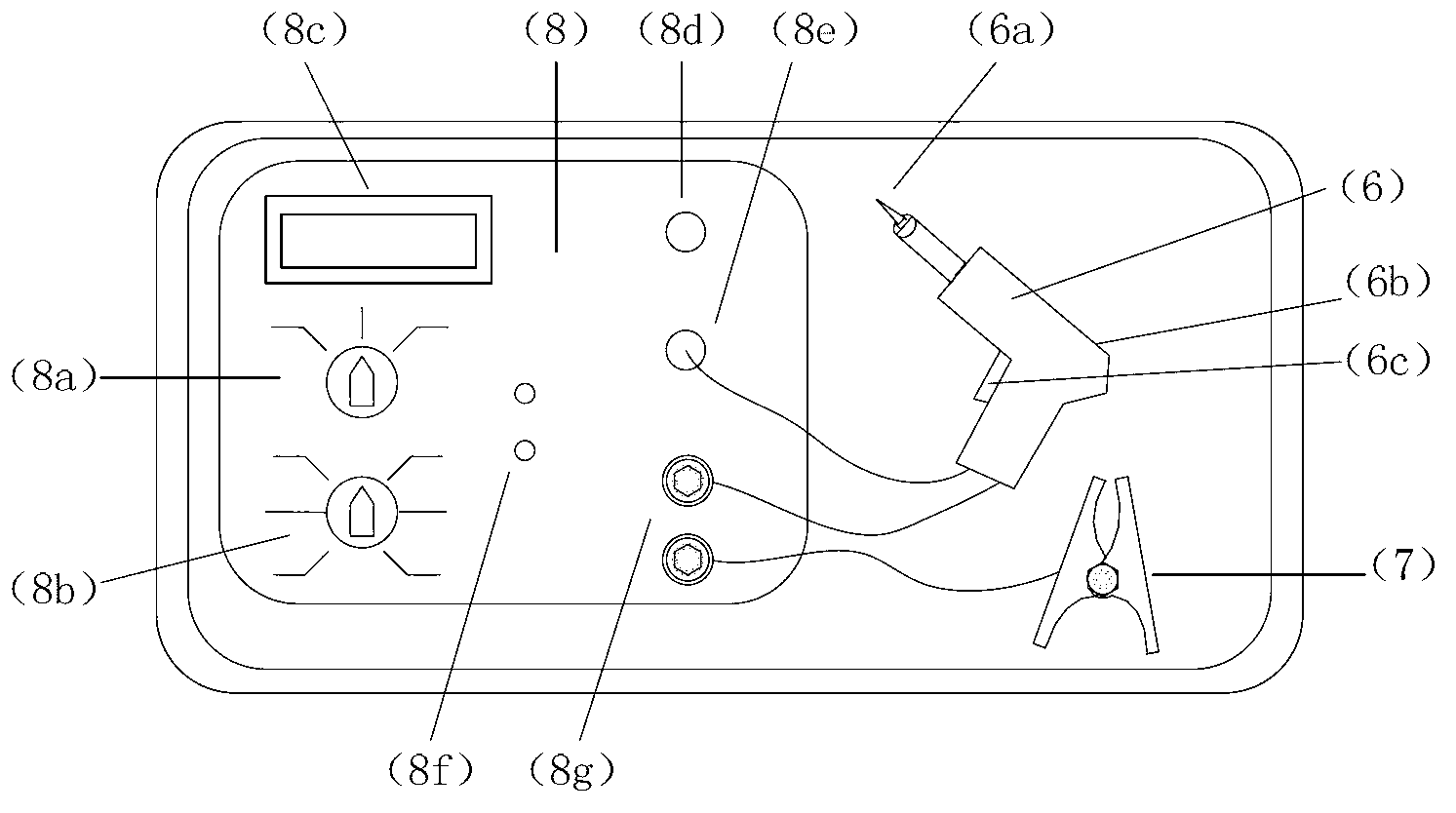

[0020] Such as figure 1 Shown is a schematic structural diagram of the portable micro-energy storage spot welding machine of the present invention, which specifically includes a nickel-metal hydride battery pack (1) equipped with a charger, a spot welding control circuit module (2), an energy storage charging switch (3), Farad level energy storage capacitor (4), spot welding discharge switch (5), spot welding torch with manual control switch (6), grounding clamp (7) connected to the welding machine through cables, and energy adjustment and display panel (8) , wherein, the Ni-MH battery pack (1) equipped with a charger is connected to the spot welding control circuit module (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com