Process for making venetian blind blades

A manufacturing process and technology of blades, applied in the field of manufacturing technology of venetian blinds, can solve the problems of simple manufacturing process, insufficient durability and aesthetics of venetian blinds, and achieve the effect of beautiful appearance, good decorative effect, and not easy to fade paint and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

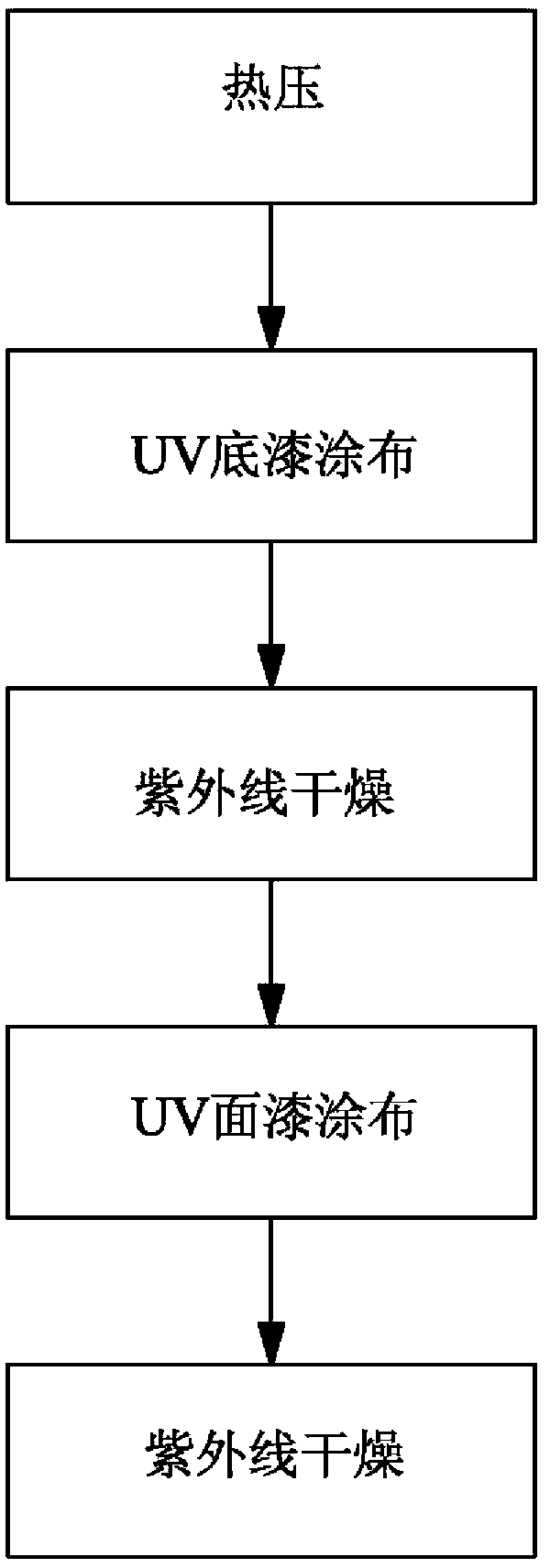

[0021] Please refer to figure 1 Shown, it shows the manufacturing process of the preferred embodiment of the present invention, including the following steps:

[0022] (1) Hot pressing, according to the user's requirements, the leaves are colored and various patterns are formed, and the colored leaves are hot-pressed by a high-temperature hot press at 170°C, so that the color is firmly attached to the leaves;

[0023] (2) UV primer coating, the UV primer is evenly rolled on the aforementioned blades that have been hot-pressed at 170°C by a single steel wheel reverse coater, and the UV primer covers the entire surface of the blade;

[0024] (3) Ultraviolet drying. The blades coated with UV primer are dried by the ultraviolet irradiation machine by the conveyor belt. At this time, the UV primer is firmly attached to the surface of the blade and fully protects the color pattern on the blade. ;

[0025] (4) UV topcoat coating, the UV environmental protection topcoat is evenly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com