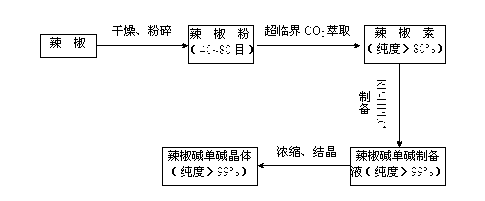

Production process of capsaicin

A production process, capsaicin technology, applied in the production of bulk chemicals, natural dyes, azo dyes, etc., can solve the problems of high sales price and difficult processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Raw material pretreatment

[0035] The peppers are vacuum-dried at low temperature (moisture content <22%), crushed (60 mesh), and set aside.

[0036] (2) Supercritical CO 2 extraction

[0037] 1. Tank washing operation of supercritical extraction device

[0038] The model of supercritical extraction device is HA120-50-01

[0039] ① First add 100ml~200ml of absolute ethanol to the extraction kettle.

[0040] ② Turn on the main power supply on the wall, turn on the main power supply of the equipment, and after the three-phase indicator light shows normal, turn on the power switch of the refrigeration and cold cycle to check whether it works normally.

[0041] ③ Before turning on the temperature control power of the extractor and separator, check whether the motor of the hot water tank can be rotated artificially, check the water level of the hot water tank, if the water level is insufficient, add water. Turn on the power switches of extraction Ⅰ, separation Ⅰ an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com