Method for preparing high-purity capsaicin monomer

A capsaicin and high-purity technology, applied in the separation/purification of carboxylic acid amides, organic chemistry, etc., can solve the problems of difficult quality control, high price, and inability to separate, and achieves a mild separation environment, short separation time, and no loss of samples Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: get capsicum 3000g pulverize and extract with 80% ethanol reflux 3 times (every time 1h), suction filtration, filtrate depressurizes to near dryness, add the diethyl ether and sherwood oil mixed solution that volume ratio is 1: 6 recrystallization, Place to obtain capsicum total alkaloid crude extract 9.3g, separate and prepare high-purity capsaicin monomer with the method of the present invention.

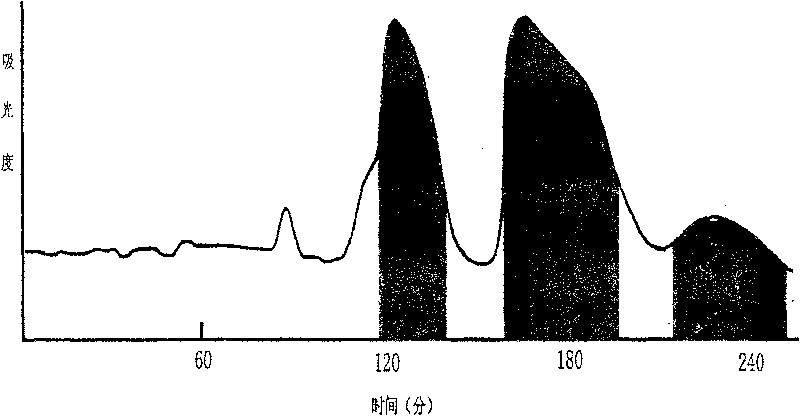

[0022] A semi-preparative high-speed countercurrent chromatograph is used to separate and prepare high-purity capsaicin monomer from capsicum total alkaloids with carbon tetrachloride, chloroform, ethanol and water as the solvent. First, carbon tetrachloride, chloroform, ethanol and water are used to configure the above solvent system in a separatory funnel with a volume ratio of 3:1:4:2, shake it up and let it stand for stratification. Separate the upper and lower phases, take the upper phase as the stationary phase, and the lower phase as the mobile phase, a...

Embodiment 2

[0024] Example 2: After taking 3000g of capsicum and pulverizing it, extract it 3 times with 60% ethanol under reflux (each time for 1h), filter it with suction, depressurize the filtrate to nearly dryness, add a mixed solution of diethyl ether and sherwood oil with a volume ratio of 1:6 for recrystallization, Place to obtain capsicum total alkaloid crude extract 8.5g, separate and prepare high-purity capsaicin monomer with the method of the present invention.

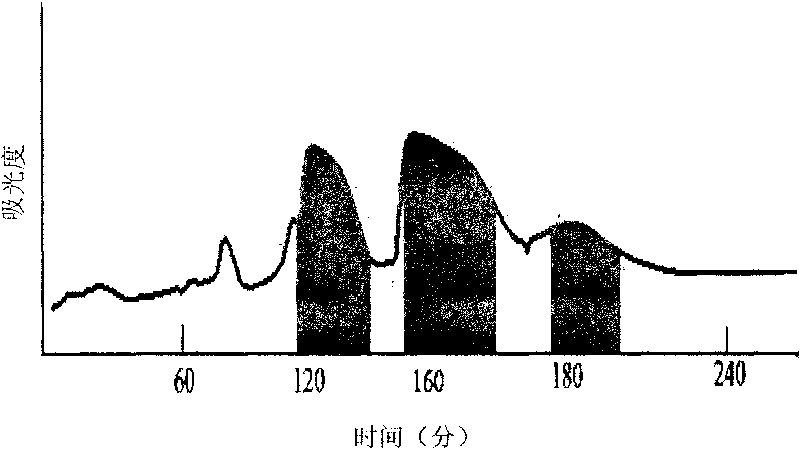

[0025]A semi-preparative high-speed countercurrent chromatograph is used to separate and prepare high-purity capsaicin monomer from total alkaloids of capsicum by using dichloromethane, methanol and water as solvents. Firstly, dichloromethane, methanol and water are arranged in the above-mentioned solvent system in a separatory funnel at a volume ratio of 4:3.5:2, shake well and then stand for stratification. After a period of equilibrium, the upper and lower phases are separated, and the upper and lower phases are take...

Embodiment 3

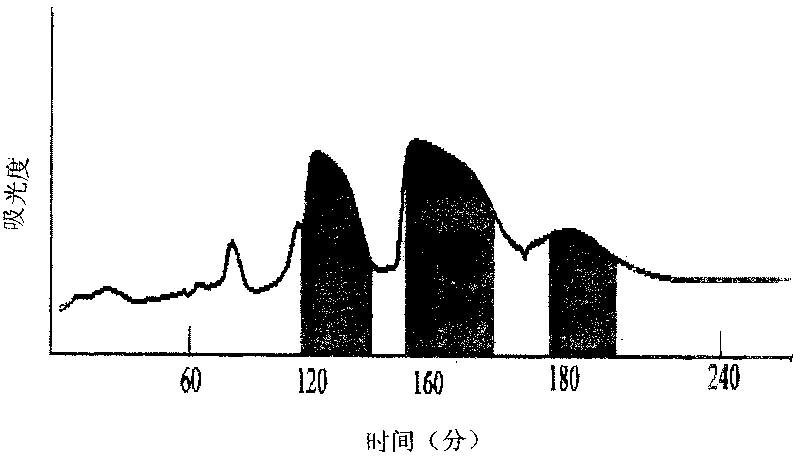

[0028] Embodiment 3: Separation The selected solvent system is carbon tetrachloride: methylene chloride: methanol: water is 3: 1: 1: 2, and the rest of the test steps are the same as in Example 1. 35 mg of dihydrocapsaicin with a purity of 98.4%, 74 mg of capsaicin with a purity of 99.3%, and 2.61 mg of nordihydrocapsaicin with a purity of 98.2% were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com