Surface protection sheet

A protective sheet and vinyl technology, applied to film/sheet-shaped adhesives, adhesive types, safety equipment, etc., can solve problems such as surface protection sheet breakage, reduced operability, and surface protection sheet floating, and achieve Good workability, prevention of breakage, and outstanding effect of preventing floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

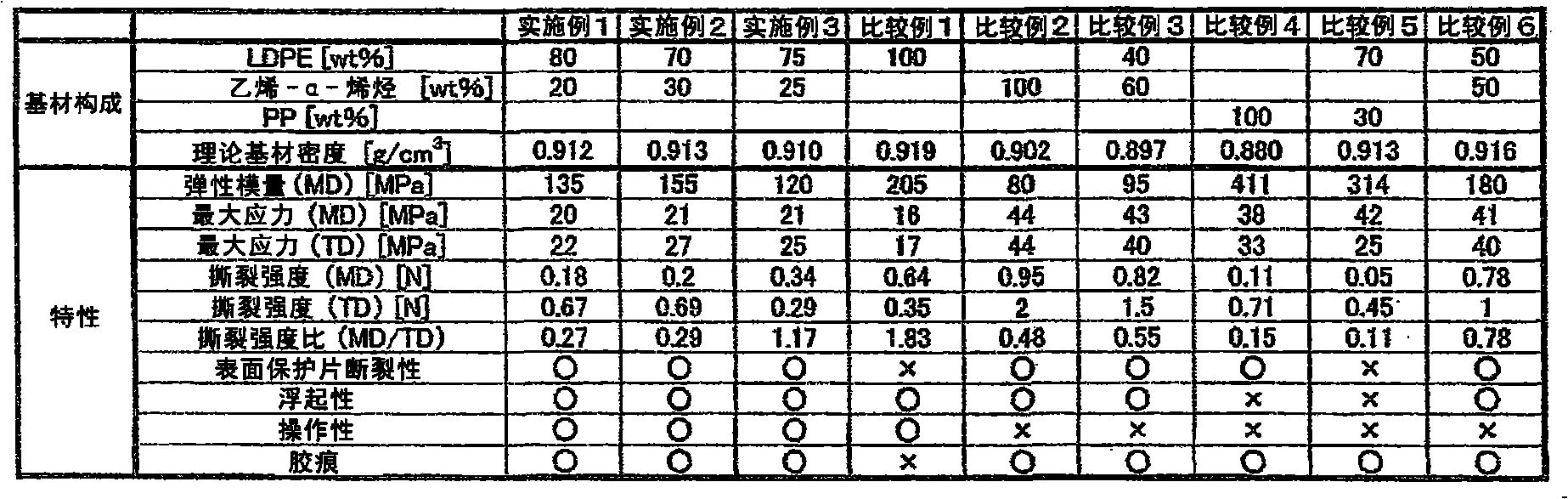

Embodiment 1

[0066] Relative to the density of 0.919g / cm 3 Low-density polyethylene (Sumitomo Mitsui Polyolefin Co., Ltd., Sumikasen F-218) 80% by weight, and a density of 0.882g / cm 3 A resin mixture consisting of 20% by weight of ethylene-octene copolymer (Exxon Mobil, EXACT8201), mixed with 3.8% by weight of carbon black (manufactured by Mitsubishi Chemical, carbon black "#45"), natural silica (average particle diameter 5.0 μm) 0.2% by weight, a film was formed at a die temperature of 170° C. using a blow molding machine to produce a support base material with a thickness of 100 μm. A styrene-ethylene-butylene-styrene polymer (manufactured by Asahi Kasei Co., Ltd., Tuftec H1221) was applied to the obtained supporting substrate so that the thickness after drying was 15 μm, and dried to prepare a surface protection sheet.

Embodiment 2

[0068] Relative to the density of 0.918g / cm 3 70% by weight of low-density polyethylene (manufactured by Japan Polychem Corporation, Nobatec LD LC-500), and a density of 0.902g / cm 3 A resin mixture composed of 30% by weight of an ethylene-octene copolymer (Exxon Mobil, EXACT0201), mixed with 3.8% by weight of carbon black (manufactured by Mitsubishi Chemical, carbon black "#45"), and a weather-resistant stabilizer (Ciba Specialty Chemicals Chimassorb 944 (manufactured by the company) 0.1% by weight was formed into a film at a die temperature of 200° C. using a blow molding machine to produce a supporting base material having a thickness of 80 μm. A solution obtained by dissolving a propylene-based copolymer (manufactured by Sumitomo Chemical Co., Ltd., Tafthren X2135) in a toluene solution and filtering it was applied to the obtained support substrate so that the thickness after drying was 5 μm, and dried to prepare a surface Protective sheet.

Embodiment 3

[0070] Relative to the density of 0.919g / cm 3 Low-density polyethylene (Sumitomo Mitsui Polyolefin Co., Ltd., Sumikasen F-218) 75% by weight, and a density of 0.882g / cm 3 A resin mixture composed of 25% by weight of ethylene-octene copolymer (manufactured by Exxon Mobil, EXACT8201), mixed with 3.8% by weight of carbon black (manufactured by Mitsubishi Chemical, carbon black "#45"), lubricant (manufactured by NOF Corporation, Alflow H50S) 0.6% by weight, the obtained substrate layer component and the adhesive layer component composed of styrene-ethylene-butylene-random polymer (manufactured by JSR Corporation, Dynaron 2324P) were heated at 200° C. The die head temperature was formed into a film by co-extrusion, and a surface protection sheet composed of a base material layer of 110 μm and an adhesive layer of 8 μm was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com