Colored laminating adhesive

A color laminating adhesive and laminating adhesive technology, applied in the field of colored laminating adhesive, can solve the problems of increased production and use costs, and achieve the effects of stable comprehensive performance, good brightness and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of colored laminating glue, described colored laminating glue comprises the following components by mass fraction:

[0050] Organic pigment 10~20%

[0051] Laminating glue 80~90%

[0052] Wherein, the organic toner comprises the following components by mass fraction:

[0053] Organic toner 40~45%

[0054] Acrylic emulsion 55~60%

[0055] Wherein, laminating adhesive comprises the following components by mass fraction:

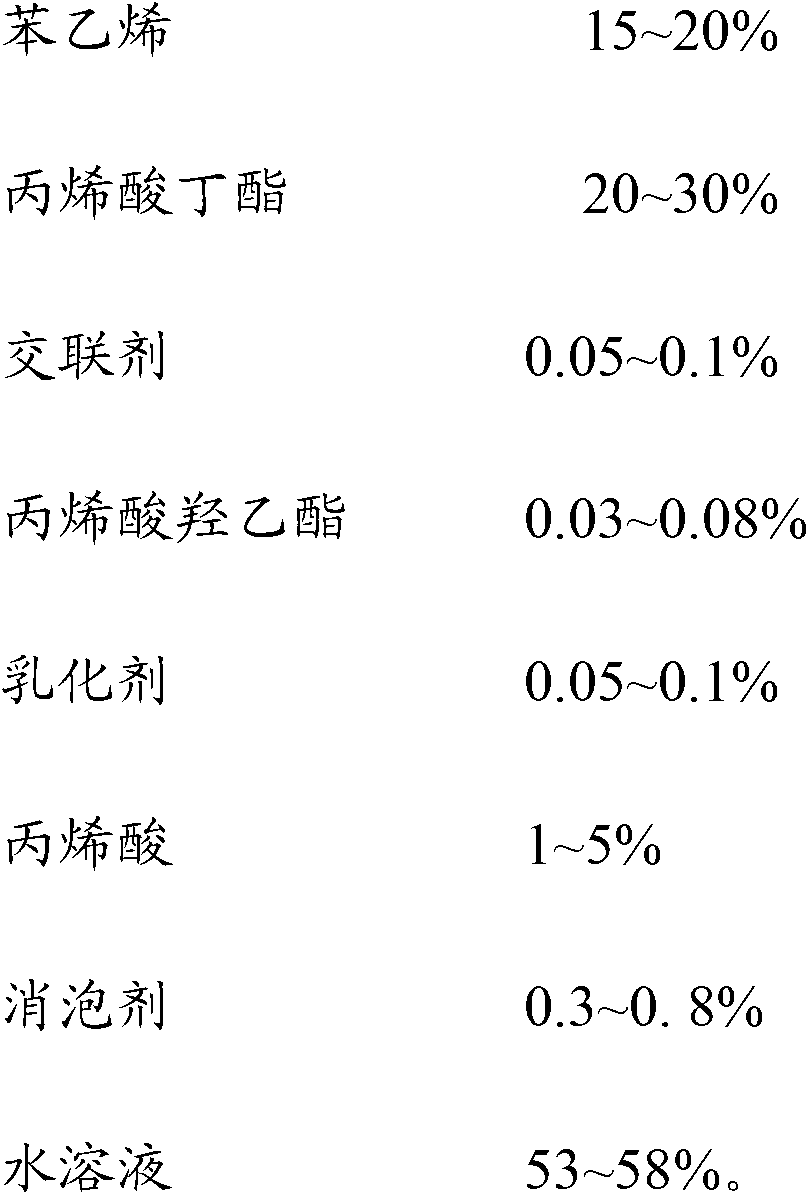

[0056]

[0057] The organic pigments include organic toners and acrylic emulsions with fixed contents, and the organic toners include acrylic pigments in various combinations of madder blue, gamboge, and pink purple. The viscosity of the acrylic emulsion: (CP25) 300-1000, the solid content is not less than 49%, the pH value is about 8.5, the tg is not less than 105, and the acid value is fixed at 55. The emulsifier includes polyoxyethylene oleate, polyoxyethylene stearate, polyoxyethylene abietate, polyol fatty acid ester, castor oil ethyl...

Embodiment 2

[0061] A kind of colored laminating glue, described colored laminating glue comprises the following components by mass fraction:

[0062] Organic pigment 13~18%

[0063] Laminating glue 82~87%

[0064] Wherein, the organic toner comprises the following components by mass fraction:

[0065] Organic toner 41~44%

[0066] Acrylic emulsion 56~59%

[0067] Wherein, laminating adhesive comprises the following components by mass fraction:

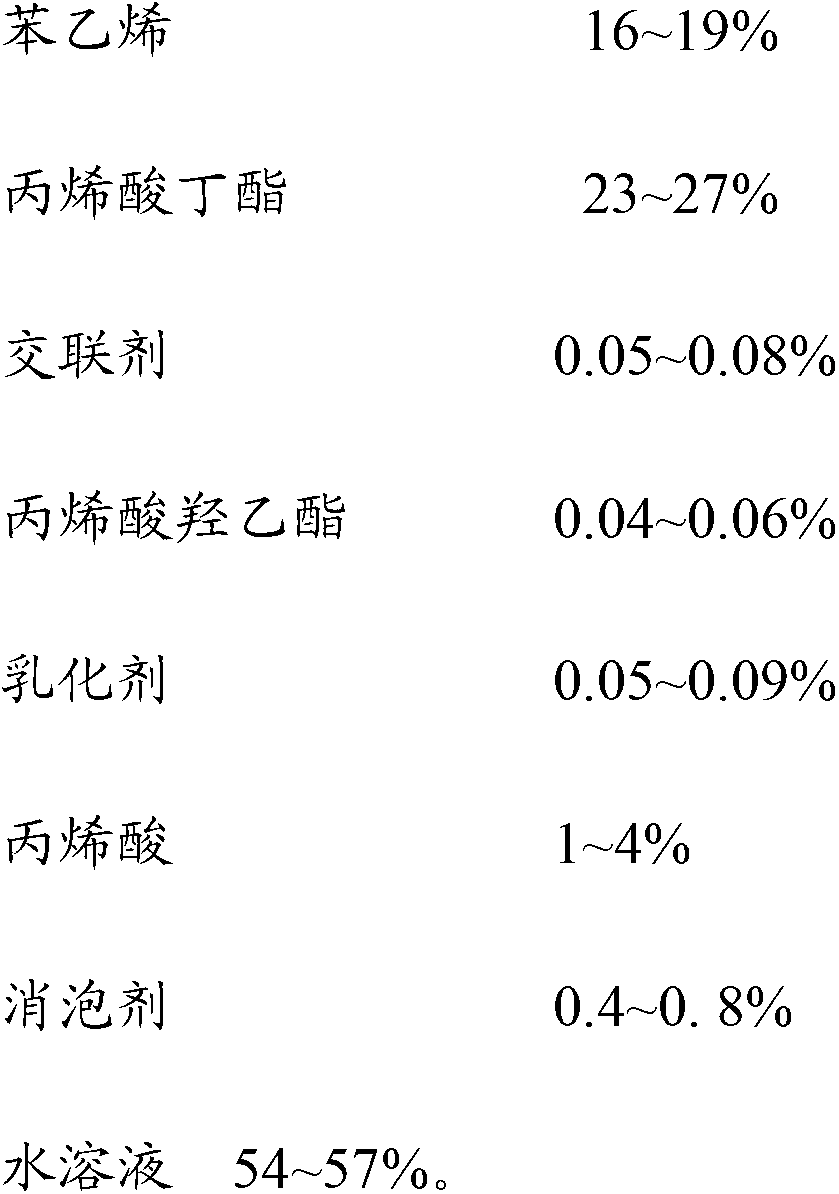

[0068]

[0069]

[0070] The organic pigments include organic toners and acrylic emulsions with fixed content, and the organic toners include acrylic pigments in various combinations of madder blue, gamboge, and pink purple. The viscosity of the acrylic emulsion: (CP25) 300-1000, the solid content is not less than 49%, the pH value is about 8.5, the tg is not less than 105, and the acid value is fixed at 55. The emulsifier includes polyoxyethylene oleate, polyoxyethylene stearate, polyoxyethylene abietate, polyol fatty acid ester, castor ...

Embodiment 3

[0074] A kind of colored laminating glue, the colored laminating glue comprises the following components by mass fraction:

[0075] Organic pigment 14~18%

[0076] Laminating glue 83~86%

[0077] Wherein, the organic toner comprises the following components by mass fraction:

[0078] Organic toner 41~43%

[0079] Acrylic emulsion 57~59%

[0080] Wherein, laminating adhesive comprises the following components by mass fraction:

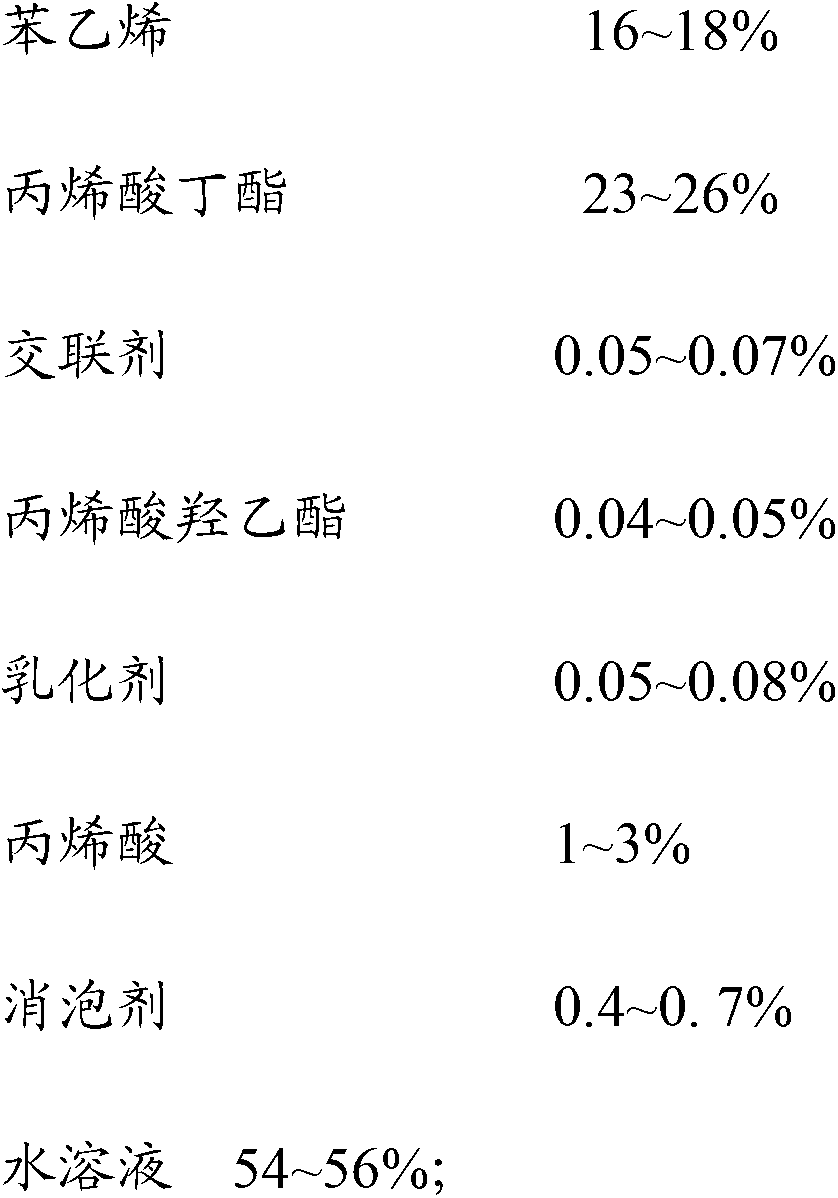

[0081]

[0082] The organic pigments include organic toners and acrylic emulsions with fixed content, and the organic toners include acrylic pigments in various combinations of madder blue, gamboge, and pink purple. The viscosity of the acrylic emulsion: (CP25) 300-1000, the solid content is not less than 49%, the pH value is about 8.5, the tg is not less than 105, and the acid value is fixed at 55. The emulsifier includes polyoxyethylene oleate, polyoxyethylene stearate, polyoxyethylene abietate, polyol fatty acid ester, castor oil ethylene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com