Large-span greenhouse and construction method thereof

A large-span, greenhouse technology, applied in the direction of building structure, botany equipment and methods, construction, etc., can solve the problems of short life, complex structure, and insufficient firmness, and achieve long life, simple structure, easy placement and transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

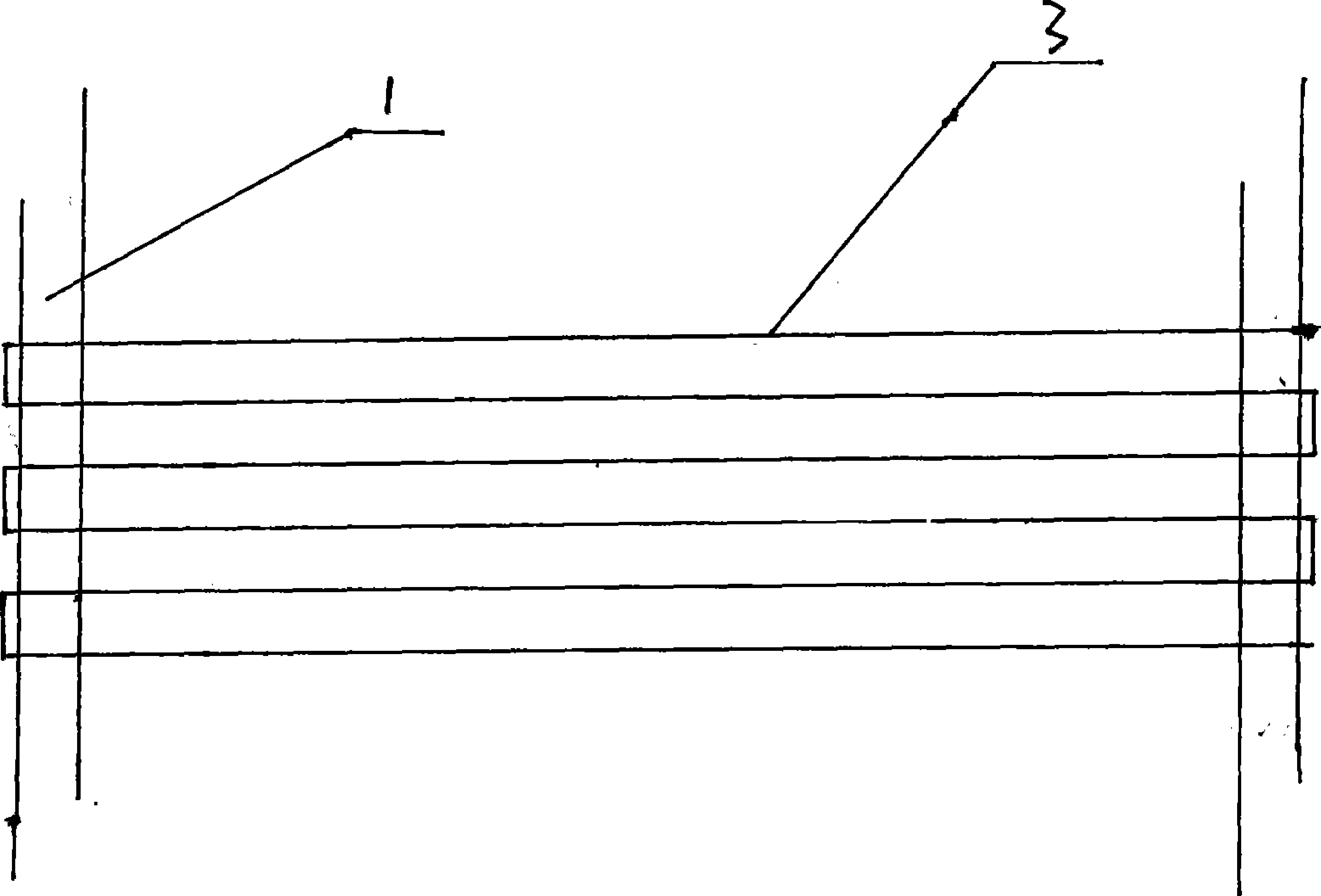

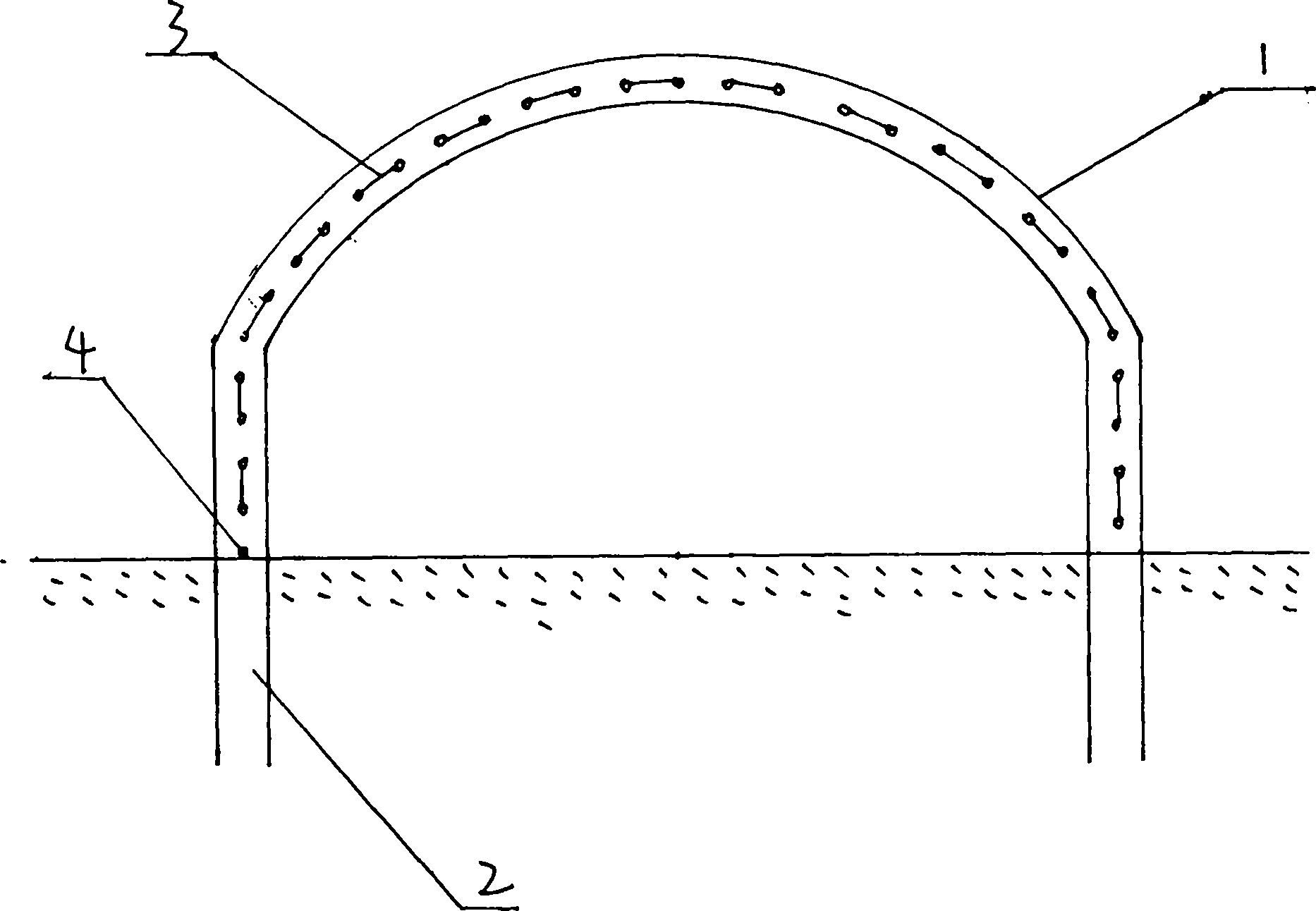

[0021] Build a large-span greenhouse with an integrated structure of ground piles and frames. This scheme is more suitable for implementation when the amount of construction is small and the specifications of the greenhouses are inconsistent.

[0022] First drill a deep well underground, the depth of the well is proportional to the span of the greenhouse, and the cross section of the well is greater than or equal to the cross section size of the frame.

[0023] Then build the formwork for the frame on the side of the well, place the ground piles and the steel bars inside the frame, and the steel bars should be an integral structure.

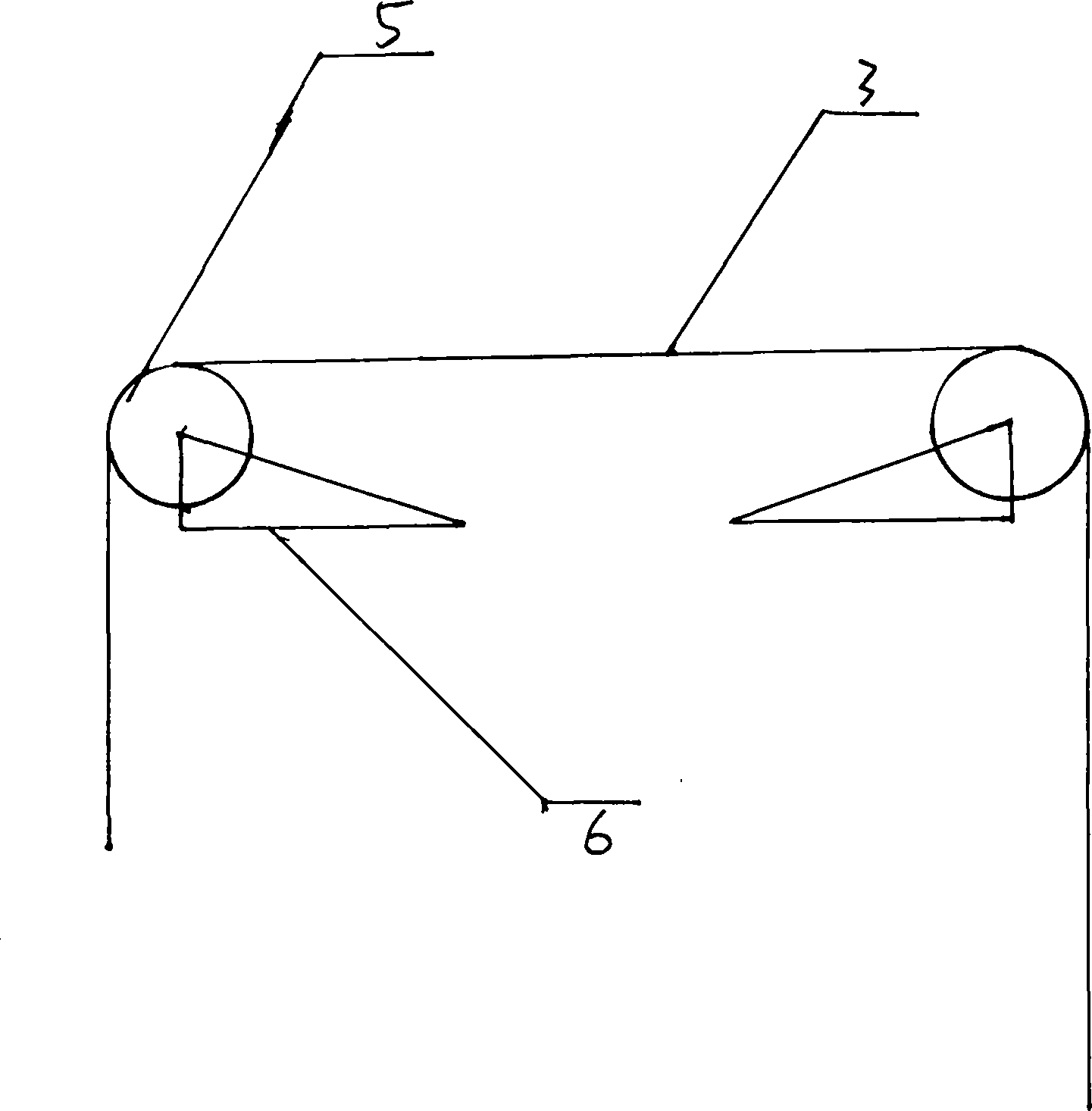

[0024] Then pouring with concrete (leave the hole (4) that wears steel cable when pouring, also can leave the hole or pit of fixing fixed pulley). After the concrete is solidified, the formwork is removed to form the frame (1), the reinforced concrete pile (2) and the hole (4) of the integrated structure.

[0025] Set up diagonal braces (not sh...

Embodiment 2

[0032] Build ground piles and frames to form a large-span greenhouse. This scheme is especially suitable for large-scale construction of greenhouses with standard specifications, and the construction time is relatively short using this scheme.

[0033] Process the reinforced concrete soil pile (2) and the frame (1) of the standard specifications in the factory (the connection work should be done in advance at the joint during processing) and transport the reinforced concrete soil pile (2) to the construction site with a pile driver ) into the ground and then connect the frame (1) above the ground pile.

[0034] The remaining roof weaving and tarpaulin covering methods are the same as in Embodiment 1.

[0035] This scheme is also especially suitable for the construction of multi-span greenhouses. When building multi-span greenhouses, two adjacent sheds can share a ground pile and a section vertical to the ground on the frame. The holes on the two adjacent frames only need to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com