A reflective electrochromic fabric and its preparation method

An electrochromic and reflective technology, applied in textiles and papermaking, optics, fiber processing, etc., can solve the problems of insufficient softness, large thickness, and difficulty in realizing flexibility of color-changing devices, and achieves fast change speed, simple preparation method, Rich and vivid color changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

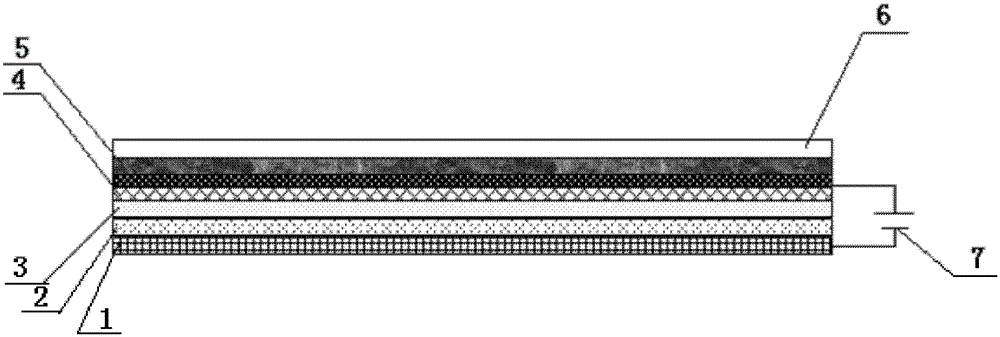

[0033] Embodiment 1, the preparation of electrochromic fabric

[0034] The polyester fabric is used as the base material, treated with 10% NaOH aqueous solution as lye, so that micropores and pits appear on the surface of the fabric, and then through the electroless plating method, metal copper and nickel are plated, and the micropores on the surface of the fabric are used. The metal and the substrate are closely combined to obtain a flexible conductive fabric with a surface resistance of 15Ω / □, which is used as the counter electrode, that is, the lower conductive fabric; the double-layer fabric woven with polyester fiber is used as the base material, and sputtered on one side of the double-layer fabric by sputtering A silver layer to obtain a flexible conductive fabric with a surface resistivity of 10Ω / □, which is used as the working electrode, that is, the upper layer of conductive fabric.

[0035] Using a DC magnetron sputtering system, sputter a nickel oxide film on the co...

Embodiment 2

[0044] Embodiment 2, the preparation of electrochromic fabric

[0045] Silver fibers and cotton fibers are used as warp yarns, arranged in a ratio of 1:1, and weft yarns are also woven with silver fibers and cotton fibers in a 1:3 arrangement to obtain a flexible conductive fabric with a surface resistance of 30Ω / □, which is used as the counter electrode, that is, the lower conductive fabric ; Double-layer fabric woven with polyester fibers is used as the base material, and a silver layer is sputtered on one side of the double-layer fabric by sputtering to obtain a flexible conductive fabric with a surface resistance of 10Ω / □, which is used as the working electrode, that is, the upper conductive fabric.

[0046] Polyaniline (PANI) is coated on the counter electrode with a thickness of 200 μm as an ion storage layer; the side of the silver plated side of the working electrode is coated with aniline / o-phenylenediamine copolymer with a thickness of 200 μm as an electrochromic poly...

Embodiment 3

[0054] Embodiment 3, the preparation of electrochromic fabric

[0055] Silver fibers and cotton fibers are used as warp yarns, arranged in a ratio of 1:2, and weft yarns are also woven with silver fibers and cotton fibers in a 1:3 arrangement to obtain a flexible conductive fabric with a surface resistance of 35Ω / □, which is used as the counter electrode, that is, the lower conductive fabric ; Double-layer fabric woven with nylon fiber is used as the base material, and a silver layer is sputtered on one side of the double-layer fabric by sputtering to obtain a flexible conductive fabric with a surface resistance of 15Ω / □, which is the upper conductive fabric as the working electrode.

[0056] Polyaniline (PANI) is coated on the counter electrode with a thickness of 200 μm as an ion storage layer; the silver-plated side of the working electrode is coated with poly-3-hexylthiophene (in the form of a tetrahydrofuran solution of poly-3-hexylthiophene) Coating: Dissolve poly 3-hexy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com