Method for manufacturing molded glass plate, and device for manufacturing molded glass plate

A manufacturing method and manufacturing device technology, applied in the field of glass ribbons, can solve the problems of manufacturing cost, equipment cost, redundant grinding time and labor, etc., and achieve the effect of excellent flexibility and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

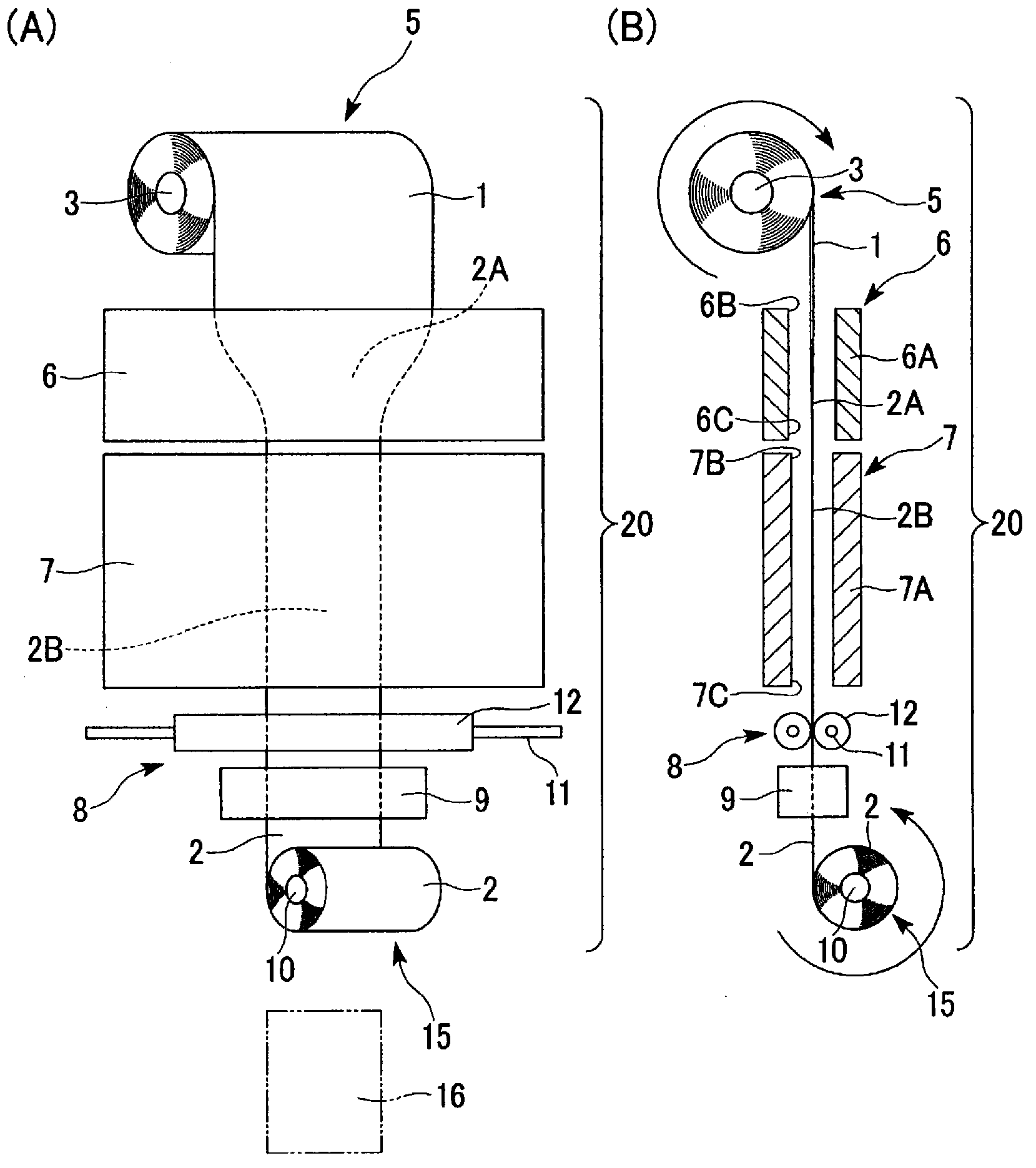

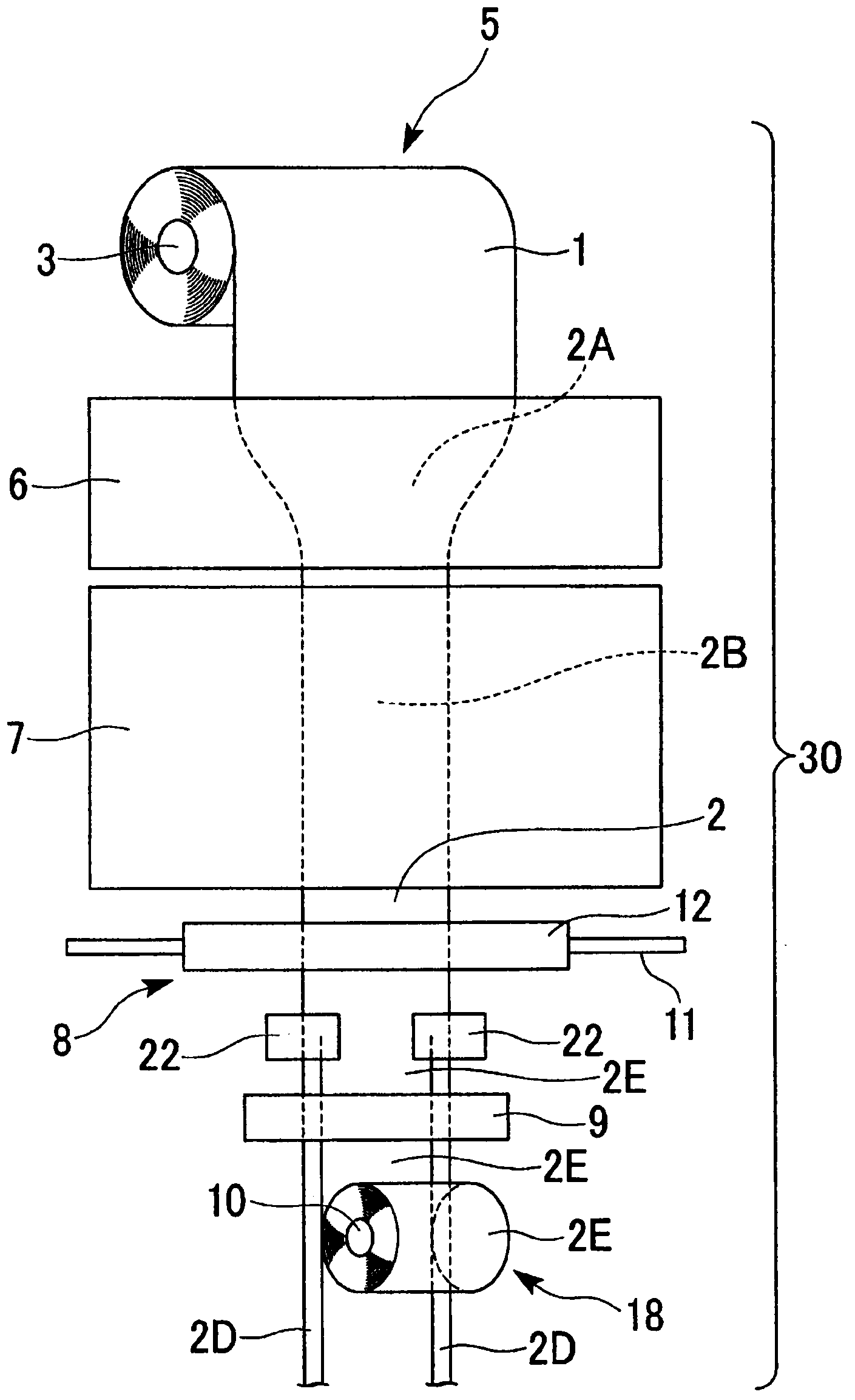

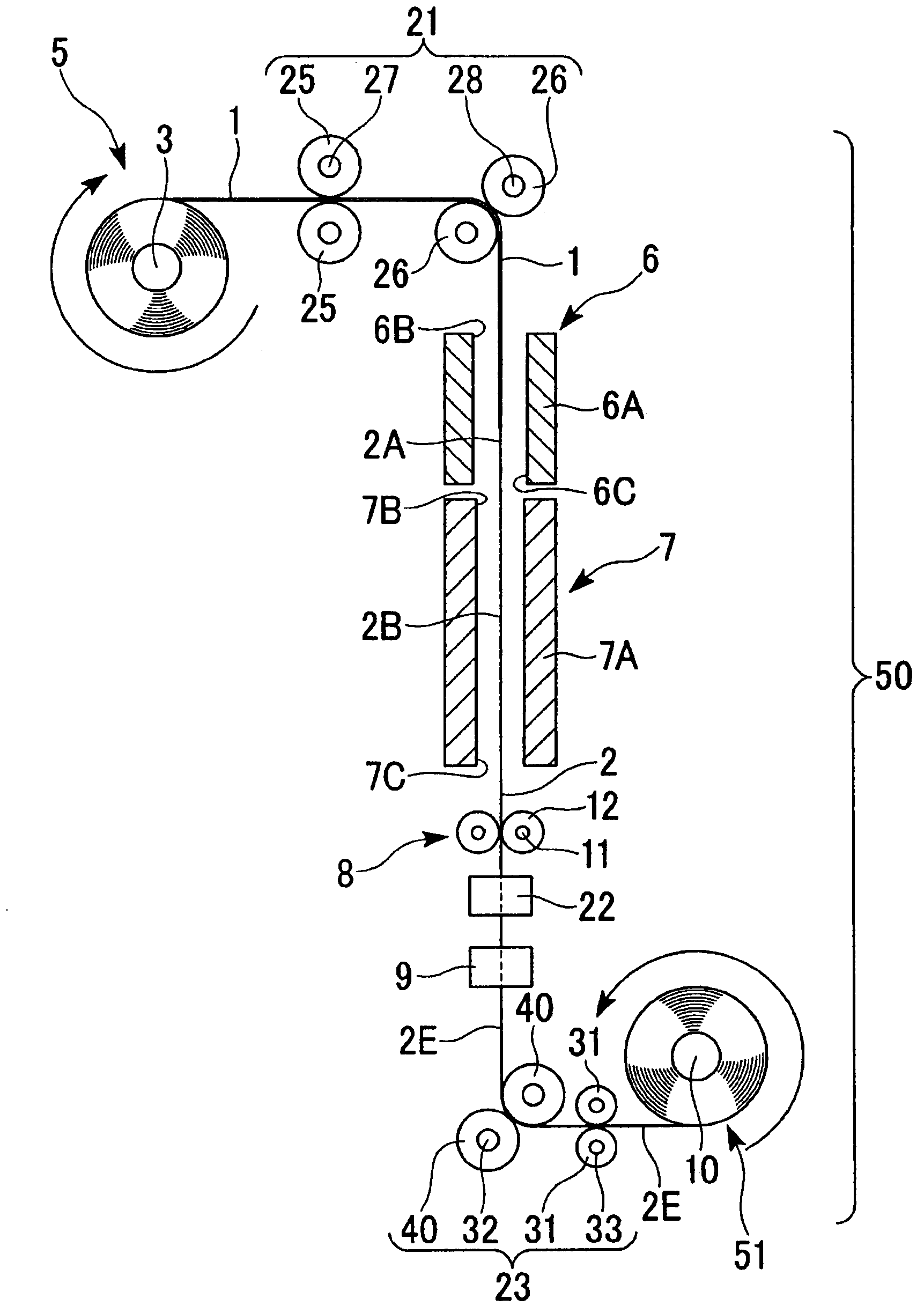

[0050] Hereinafter, 1st Embodiment of the manufacturing apparatus of the glass plate molded article of this invention is demonstrated based on drawing, but this invention is not limited to the following embodiment. In addition, in each of the drawings shown below, the scale of each component is simplified for easy understanding when drawing.

[0051] figure 1 It is a figure showing the overall structure of the manufacturing apparatus of the glass plate molded product of this invention, and the manufacturing apparatus 20 of the glass plate molded product of this embodiment is equipped with the reel 3 which supports the glass plate base material 1 which consists of plate-shaped glass horizontally. A base material supply device 5 wound up into a cylinder, a heating device 6, a slow cooling device 7, a pulling device 8, a cutting device 9 (first cutting device), a roll Winding device (reel) 10.

[0052] Here, the glass plate base material is a raw material (base material) befor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com