Method for preparing tetrahedral silver phosphate photocatalyst

A technology of tetrahedron and catalyst, which is applied in the field of photocatalysis, can solve the problems of large particle radius dispersion, silver phosphate particles without regular shape size, and irregular shape, etc., to achieve large-scale promotion, low cost, and synthetic short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

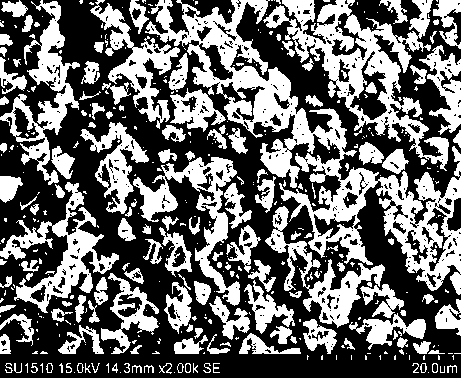

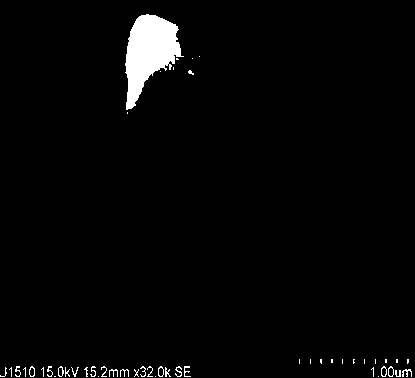

[0021] At room temperature, take 40mL of pure water (deionized water), pour it into a beaker, add 0.318g of silver nitrate under stirring conditions, then add 0.315g of urotropine, stir well, and finally add 123μL of phosphoric acid, stir After five minutes, centrifuge to wash the precipitate, and dry it at 60°C to obtain tetrahedral silver phosphate. figure 1 , figure 2 It is a scanning electron microscope image (SEM) of the product prepared in this embodiment, and it can be seen from the figure that it is tetrahedral.

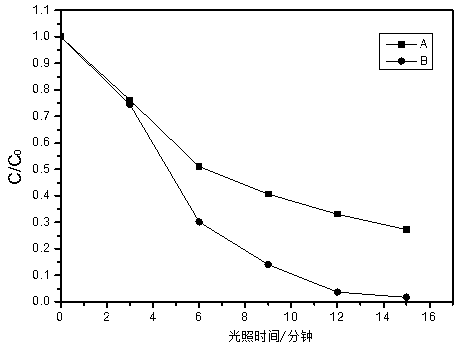

[0022] The obtained tetrahedral silver phosphate and dodecahedral silver phosphate were used as catalysts to degrade Rhodamine B. Weighed 100mg sample and added 200mL Rhodamine B solution (10-50mg / L), and stirred in the dark for 30 minutes to make the Rhodamine B solution Adsorption / desorption equilibrium is reached on the catalyst surface. Then turn on the light source for photocatalytic reaction, take 15mL reaction solution every 3 minutes, after centri...

Embodiment example 2

[0024] At room temperature, take 40mL of pure water (deionized water), pour it into a beaker, add 0.3g of silver nitrate under stirring conditions, then add 0.2g of urotropine, stir well, and finally add 100μL of phosphoric acid, stir After five minutes, centrifuge to wash the precipitate, and dry it at 40°C to obtain tetrahedral silver phosphate.

Embodiment example 3

[0026] At room temperature, take 40mL of pure water (deionized water), pour it into a beaker, add 0.4g of silver nitrate under stirring conditions, then add 0.4g of urotropine, stir well, and finally add 130μL of phosphoric acid, stir After five minutes, centrifuge to wash the precipitate, and dry it at 50°C to obtain tetrahedral silver phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com