Tubular TiO2 synthesis method and application of tubular TiO2

A synthetic method, a tubular technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, titanium oxide/hydroxide, etc., can solve the problems of high temperature and pressure of hydrogen absorption and desorption, poor reversibility, etc. Achieve the effects of improved hydrogen release performance, easy control of reaction conditions and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A tubular TiO 2 The synthetic method comprises the following steps:

[0027] 1) Add 0.3120 g TiOSO 4 Dissolve in a mixed solution of 30 ml of ethanol and 15 ml of glycerol, then add 15 ml of ether, stir well to obtain a mixed solution;

[0028] 2) Transfer the above mixed solution to a high-pressure reactor, and then put it into a homogeneous reactor for heating and constant temperature reaction. The reaction temperature is 110 °C, and the reactor speed is 10 °C / min. After 48 h of reaction, it is cooled naturally. A white precipitate is formed;

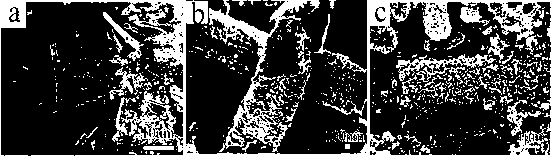

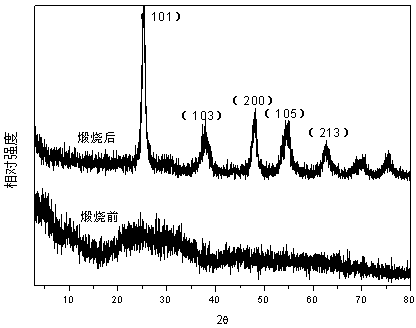

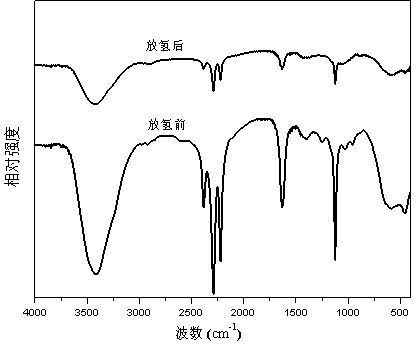

[0029] 3) After the resulting white precipitate was centrifuged, washed three times with absolute ethanol and deionized water, and finally washed once with absolute ethanol, then vacuum-dried at 60 °C for 12 h, and finally dried in an air atmosphere , calcination at 550 °C for 6 h, the tubular TiO 2 finished product. The obtained sample is pure phase anatase, which is consistent with the standard card JCPDS 1-562, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com