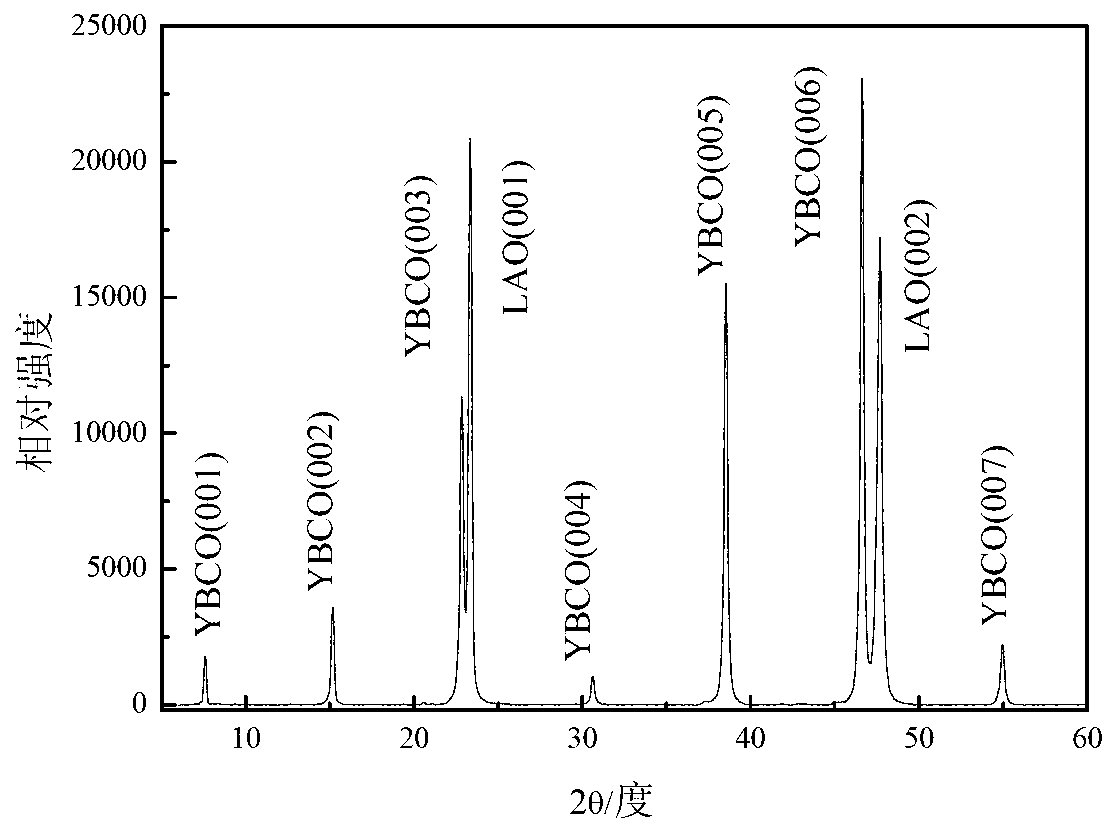

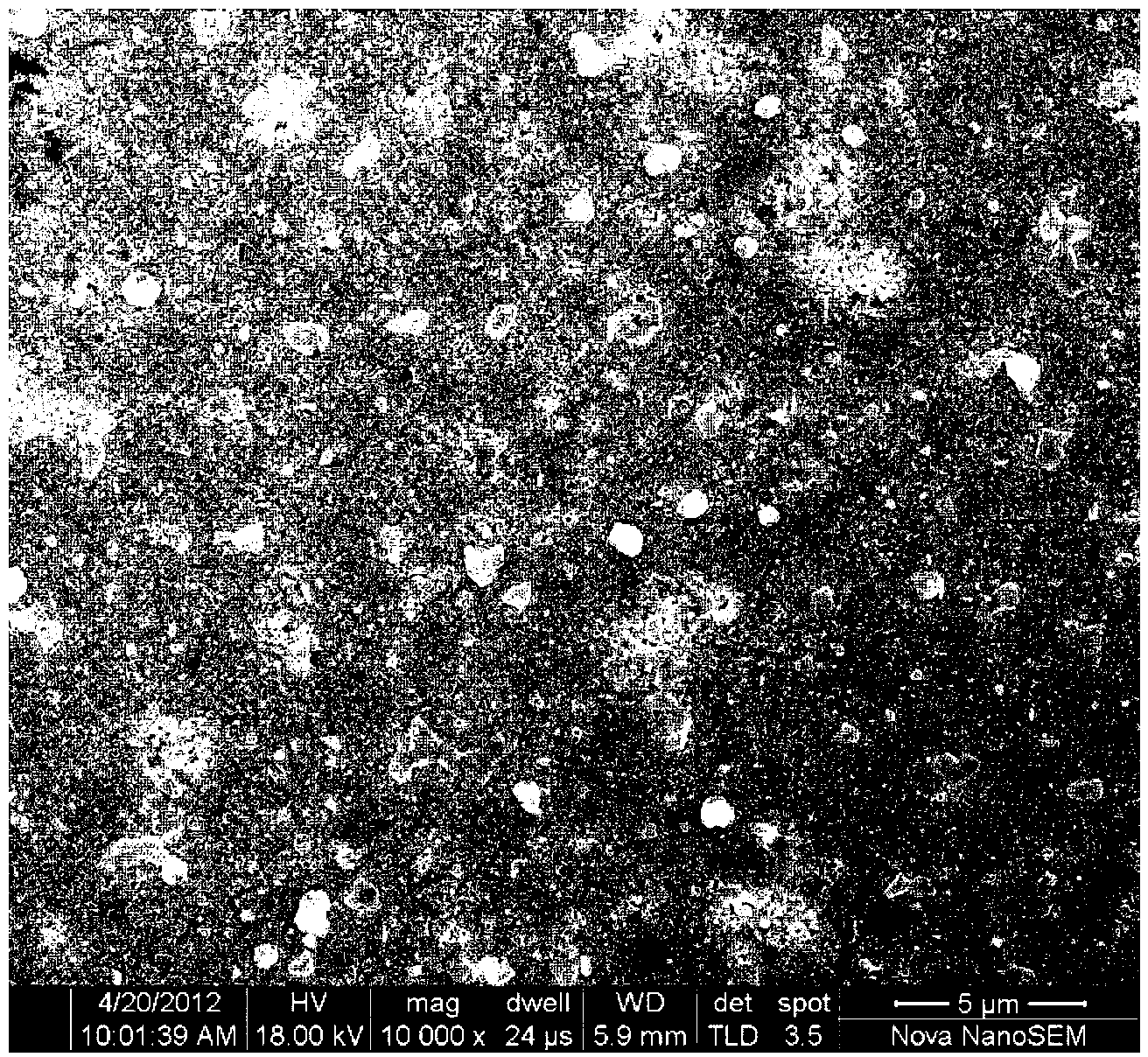

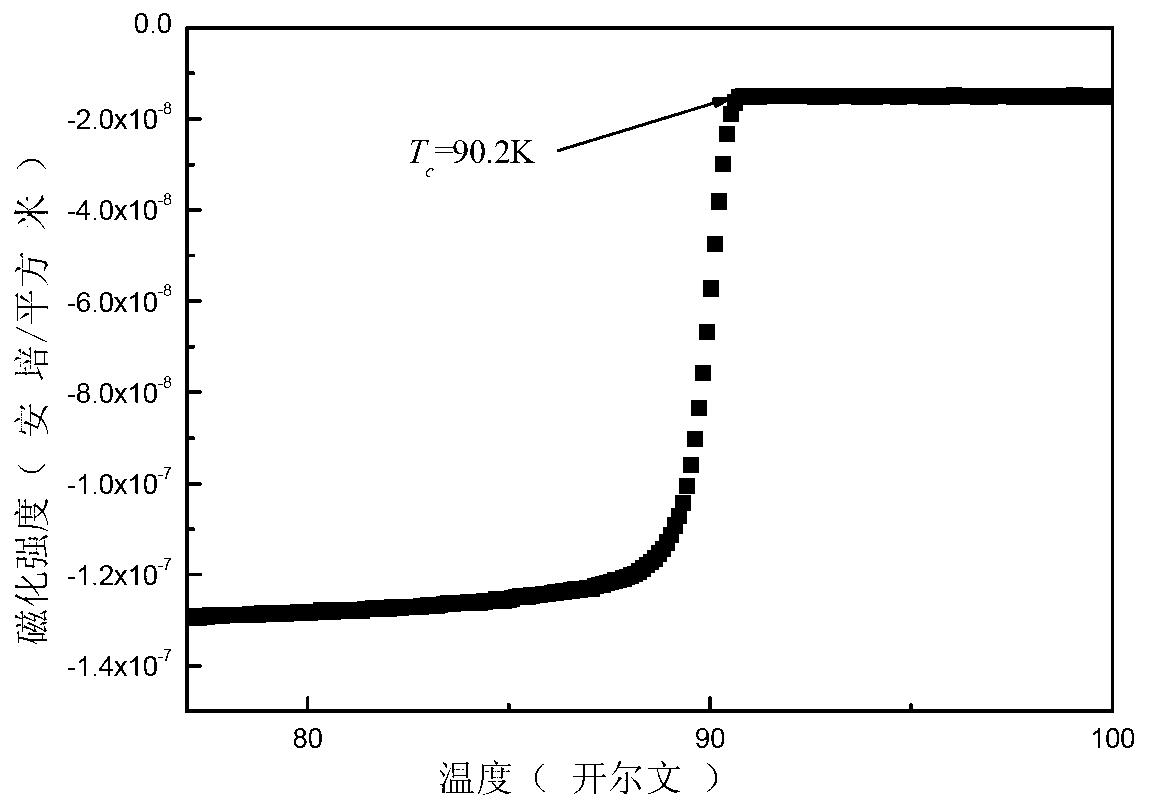

V-doped YBCO (Yttrium Barium Copper Oxide) superconducting thin film and preparation method thereof

A technology of superconducting thin film and precursor liquid, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of high cost, complex equipment, high vacuum, etc., and achieve the effect of high critical transition temperature, low cost, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of V-doped YBCO precursor:

[0026] (1) Dissolve yttrium acetate and barium acetate in deionized water at a molar ratio of 1:2. After fully stirring and dissolving at 50°C, add three Fluoroacetic acid, after reacting at 50°C for 3 hours, was rotovapped at 50°C to obtain a white powder, which was dissolved in anhydrous methanol, the precursor of Y and Ba.

[0027] (2) Dissolve copper acetate and α-methacrylic acid in anhydrous methanol at a molar ratio of 1:4, reflux at 80°C for more than 3 hours, and then rotary evaporate at 50°C to obtain a blue gel, Dissolved with anhydrous methanol to obtain Cu precursor.

[0028] (3) Filter the precursor solutions of Y, Ba, and Cu respectively and mix them to obtain a blue transparent solution. Rotate evaporation at 50°C to obtain a blue gel, and then dilute with anhydrous methanol to control the total cation concentration to 2.0mol / L, is the YBCO precursor.

[0029] (4) Add vanadium acetylacetonate (C 15 h 21 o...

Embodiment 2

[0034] 1. Preparation of V-doped YBCO precursor:

[0035] (1) Dissolve yttrium acetate and barium acetate in deionized water at a molar ratio of 1:2. After fully stirring and dissolving at 55°C, add three Fluoroacetic acid, after reacting at 55°C for 3 hours, was rotovapped at 50°C to obtain a white powder, which was dissolved in anhydrous methanol, the precursor of Y and Ba.

[0036] (2) Dissolve copper acetate and α-methacrylic acid in anhydrous methanol at a molar ratio of 1:4, reflux at 80°C for more than 3 hours, and then rotary evaporate at 50°C to obtain a blue gel, Dissolved with anhydrous methanol to obtain Cu precursor.

[0037](3) Filter the precursor solutions of Y, Ba, and Cu respectively and mix them to obtain a blue transparent solution. Rotate evaporation at 50°C to obtain a blue gel, and then dilute with anhydrous methanol to control the total cation concentration to 2.5mol / L, is the YBCO precursor.

[0038] (4) Add vanadium acetylacetonate (C 15 h 21 o ...

Embodiment 3

[0043] 1. Preparation of V-doped YBCO precursor:

[0044] (1) Dissolve yttrium acetate and barium acetate in deionized water at a molar ratio of 1:2. After fully stirring and dissolving at 60°C, add three Fluoroacetic acid, reacted at 60°C for 3 hours, then evaporated at 55°C to obtain a white powder, which was dissolved in anhydrous methanol, the precursor of Y, Ba.

[0045] (2) Dissolve copper acetate and α-methacrylic acid in anhydrous methanol at a molar ratio of 1:4, reflux at 80°C for more than 3 hours, and then rotary evaporate at 55°C to obtain a blue gel, Dissolved with anhydrous methanol to obtain Cu precursor.

[0046] (3) Filter the precursors of Y, Ba, and Cu separately and mix them to obtain a blue transparent solution. Rotate evaporation at 55°C to obtain a blue gel, which is then diluted with anhydrous methanol to control the total cation concentration to 3mol / L is the YBCO precursor.

[0047] (4) Add vanadium acetylacetonate (C 15 h 21 o 6 V), the added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com