Low-smoke aluminum hypophosphite compounded fire retardant and preparation method thereof

A technology of compounding flame retardant and aluminum hypophosphite, applied in the chemical field, can solve problems such as toxicity, and achieve the effects of reducing the reduction of polymer mechanical properties, good flame retardant and smoke suppression performance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

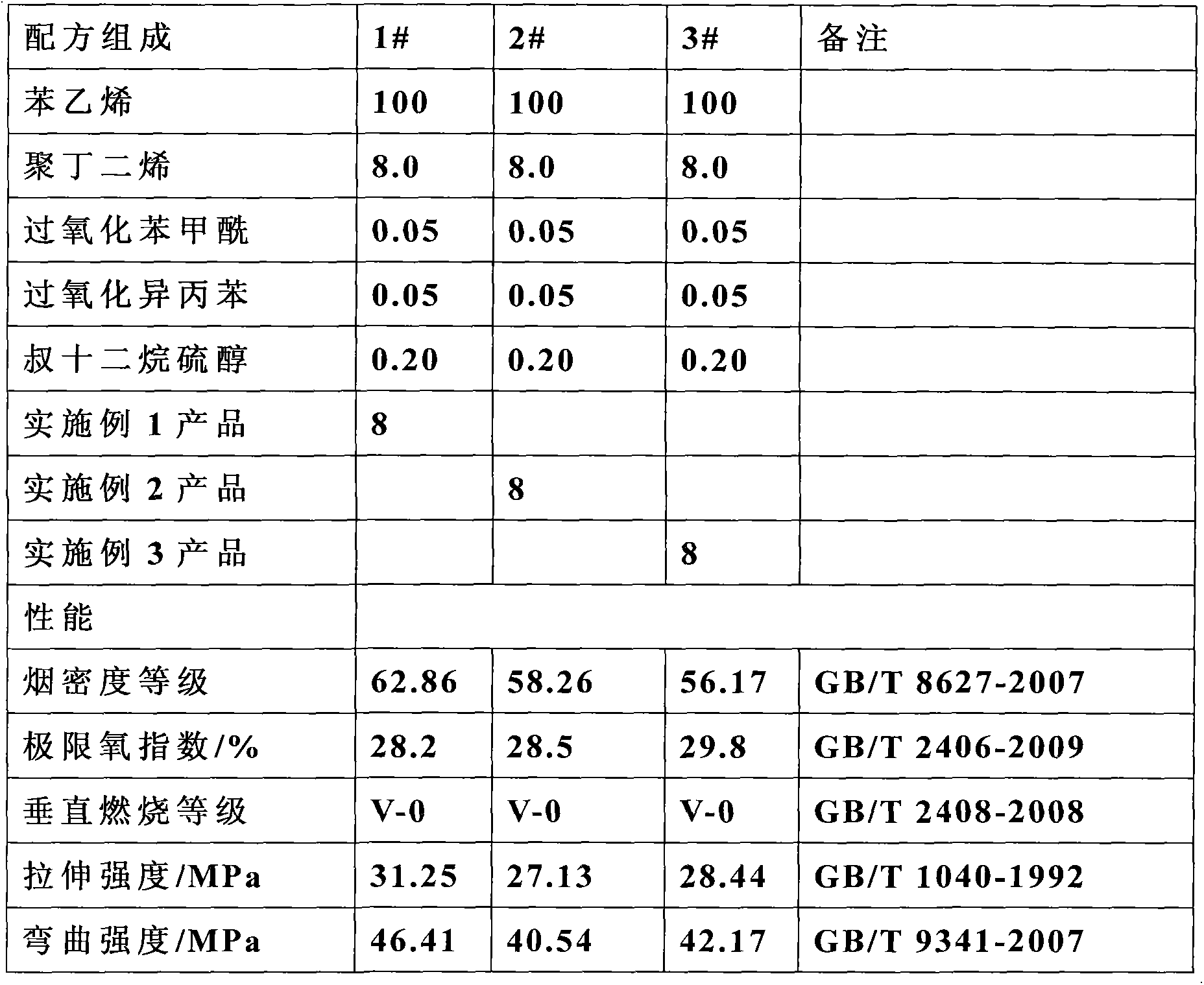

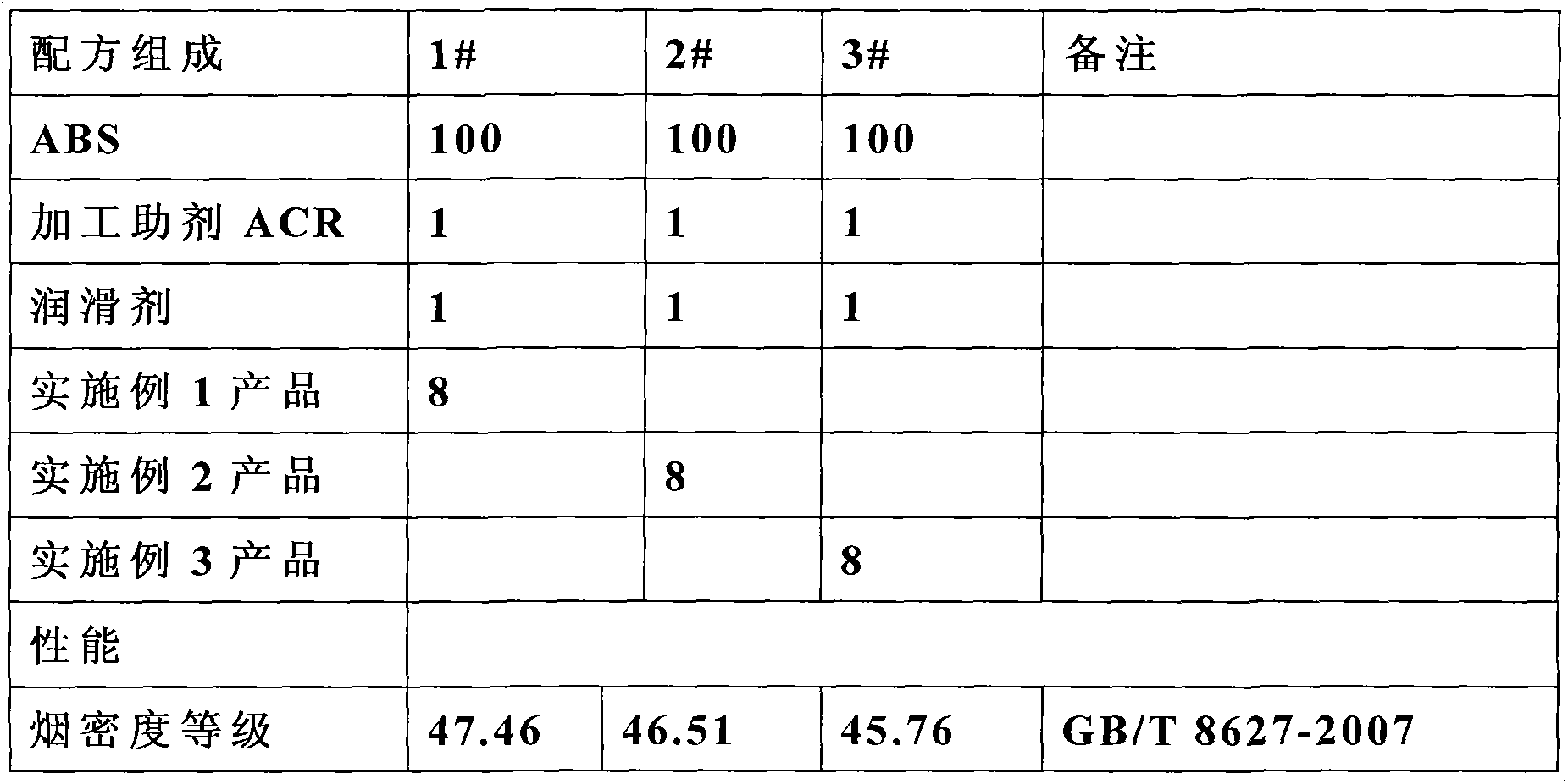

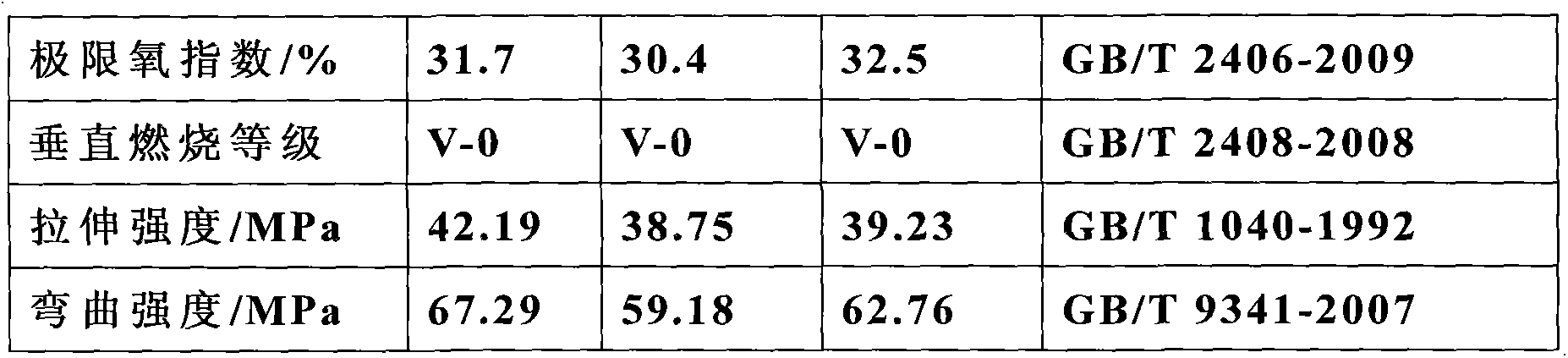

Examples

Embodiment 1

[0023] A low-smoke aluminum hypophosphite compound flame retardant, comprising the following raw materials:

[0024] Aluminum hypophosphite 25kg (main content above 99%), hydrotalcite 10kg, zinc borate 10kg, diatomaceous earth 4kg, magnesium oxide 3kg, tetrabutyl titanate coupling agent 1kg;

[0025] Its preparation method comprises the following steps:

[0026] S1. Weigh the raw materials of low-smoke aluminum hypophosphite compound flame retardant:

[0027] S2. Put the above-mentioned prepared components into a high-speed mixer with water cooling function and mix evenly, the mixing time is 40min, and control the temperature of the material in the mixer to be lower than 100°C during the mixing process;

[0028] S3. Transport the uniformly mixed material to the vibrating screen for preliminary screening, remove large particles or agglomerated materials, and then transport the preliminary screened material to the centrifugal screen for secondary screening; the vibrating screen...

Embodiment 2

[0031] The difference from Example 1 is: Weigh low-smoke aluminum hypophosphite compound flame retardant raw materials: aluminum hypophosphite 50kg (main content more than 99%), hydrotalcite 30kg, zinc borate 30kg, diatomaceous earth 8kg, oxidized Magnesium 8kg, tetrabutyl titanate coupling agent 3kg;

[0032] Its preparation method:

[0033] First, put the above-mentioned prepared components into a high-speed mixer with water cooling function and mix them evenly. The mixing time is 50 minutes, and during the mixing process, the temperature of the materials in the mixer is controlled to be lower than 100°C;

[0034] Secondly, the uniformly mixed material is sent to the vibrating screen for preliminary screening to remove large particles or agglomerated materials, and then the preliminary screened material is sent to the centrifugal screen for secondary screening; the model of the vibrating screen is ZS -650, motor 1.5kw, speed 1370rpm; centrifugal sieve model is LXS-300.

[...

Embodiment 3

[0037] The difference from Example 1 is: Weigh low-smoke aluminum hypophosphite compound flame retardant raw materials: aluminum hypophosphite 40kg (main content above 99%), hydrotalcite 15kg, zinc borate 15kg, diatomaceous earth 6kg, oxidized Magnesium 4kg, tetrabutyl titanate coupling agent 1kg;

[0038] Its preparation method is as follows:

[0039] First, put the above-mentioned prepared components into a high-speed mixer with water cooling function and mix them evenly. The mixing time is 60 minutes, and during the mixing process, the temperature of the materials in the mixer is controlled to be lower than 100°C;

[0040] Secondly, the uniformly mixed material is sent to the vibrating screen for preliminary screening to remove large particles or agglomerated materials, and then the preliminary screened material is sent to the centrifugal screen for secondary screening; the model of the vibrating screen is ZS -650, motor 1.5kw, speed 1370rpm; centrifugal sieve model is LXS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com