Brewage technique capable of enhancing trace ester content in fermented distilled white spirit

A technology of trace and esters, which is applied in the field of brewing technology to increase the content of trace esters in fermented and distilled liquor, which can solve the problems of liquor loss and achieve the effect of maintaining natural mellow aroma and improving mellow aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

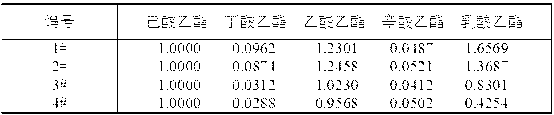

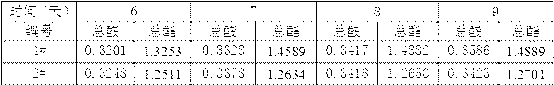

Examples

specific Embodiment

[0016] A wine-making process capable of increasing the content of trace esters in fermented and distilled liquor, comprising the following steps:

[0017] 1) Take cloves, nutmeg and woody incense, wash them, dry them, and grind them to 60-mesh powder for later use;

[0018] 2) Take 50 parts of cereal starchy raw materials by weight, wash them and add 5 parts of clove powder, 2 parts of nutmeg powder and 5 parts of woody powder, mix well and steam in a steamer for 1 to 2 hours , to obtain the clinker, and set aside; clove, nutmeg and woody spices have relatively high ester content, and the aroma after fermentation is pure, and the ester does not undergo structural transformation at the fermentation temperature;

[0019] 3) Naturally cool the clinker to 30°C, then transfer it to a fermentation container, take 0.2% of the weight of grain-based starchy raw material for brewing koji, add it to the fermentation container, stir evenly, add boiled water cooled to 30°C, and continue st...

Embodiment 1

[0027] A wine-making process capable of increasing the content of trace esters in fermented and distilled liquor, comprising the following steps:

[0028] 1) Take cloves, nutmeg and woody incense, wash them, dry them, and grind them to 60-mesh powder for later use; use a mechanical pulverizer to grind cloves, nutmeg and woody incense until they can pass through a 60-mesh sieve. The purpose is to facilitate the effective utilization of raw materials.

[0029] 2) Take 50Kg of clove powder, 20Kg of nutmeg powder, 50Kg of woody powder and 500Kg of rice in parts by weight, wash the rice, mix it evenly, put it in a steamer and steam for 1 hour to obtain clinker, and set aside;

[0030] 3) Naturally cool the clinker to 30°C, then transfer it to a fermentation container, add 5Kg of distiller's yeast, stir evenly, add boiled water cooled to 30°C, and continue stirring;

[0031] 4) Put the fermentation container into a constant temperature box, control the temperature at 36-38°C, a...

Embodiment 2

[0034] A wine-making process capable of increasing the content of trace esters in fermented and distilled liquor, comprising the following steps:

[0035] 1) Take cloves, nutmeg and woody incense, wash them, dry them, and grind them to 60-mesh powder for later use; use a mechanical pulverizer to grind cloves, nutmeg and woody incense until they can pass through a 60-mesh sieve. The purpose is to facilitate the effective utilization of raw materials.

[0036] 2) Take 50Kg of clove powder, 20Kg of nutmeg powder, 50Kg of woody powder and 500Kg of corn in parts by weight, wash the corn, mix them evenly, put them in a steamer and steam for 1 hour to obtain clinker, and set aside;

[0037] 3) Naturally cool the clinker to 30°C, then transfer it to a fermentation container, add 5Kg of distiller's yeast, stir evenly, add boiled water cooled to 30°C, and continue stirring;

[0038] 4) Put the fermentation container into a constant temperature box, control the temperature at 36-38°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com