Wire rope pickling method

A steel wire rope acid and steel wire rope technology, applied in the field of steel wire rope manufacturing, can solve the problems of extensive pickling process, repeated use of materials, waste, etc., and achieve the effects of improving adhesion and anti-corrosion ability, improving protection, and preventing re-corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

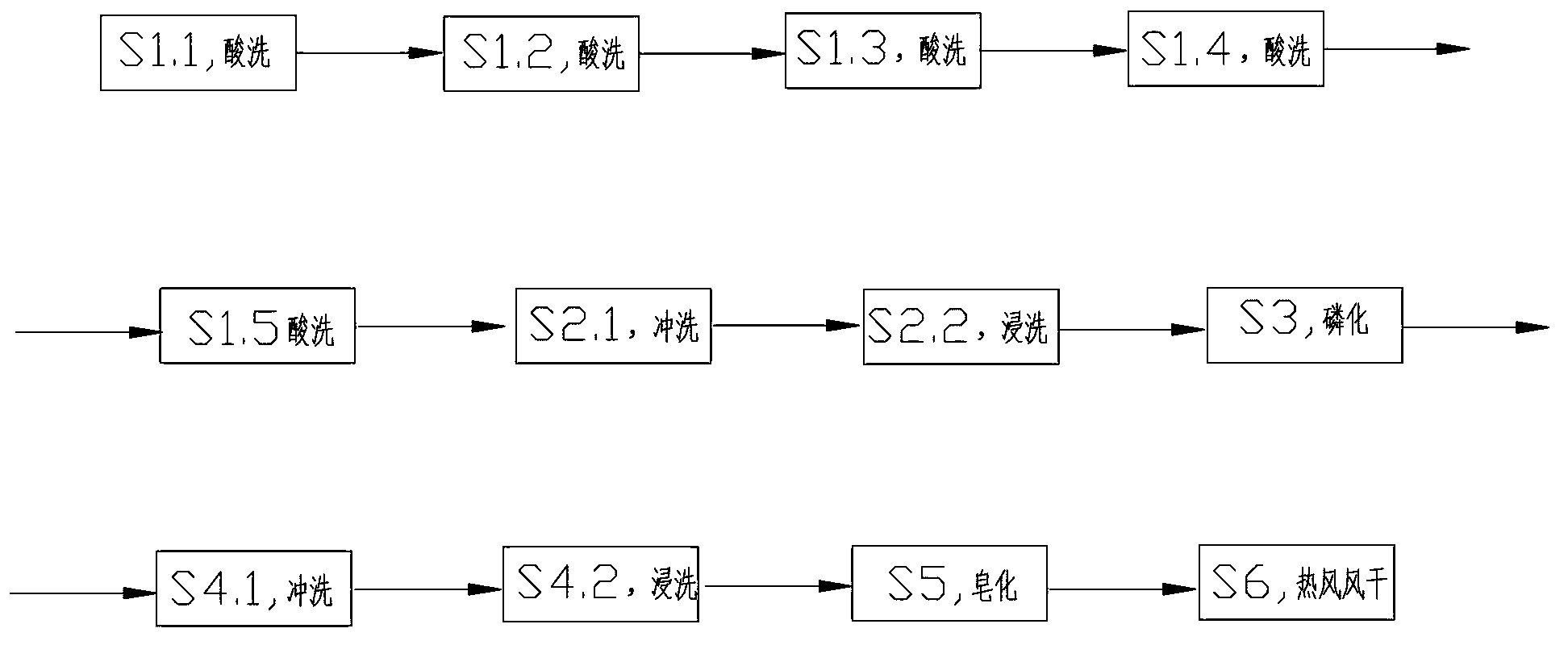

[0023] Embodiment 1: as figure 1 As shown, the invention discloses a steel wire rope pickling method, comprising:

[0024] S1.1. Immerse the steel wire rope in a hydrochloric acid solution with a mass concentration of 9%, and soak for 5 minutes at 28°C.

[0025] S1.2. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.1 in the hydrochloric acid solution with a mass concentration of 12%, and soak for 5 minutes at 28°C.

[0026] S1.3. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.2 into the hydrochloric acid solution with a mass concentration of 15%, and soak for 5 minutes at 28°C.

[0027] S1.4. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.3 into the hydrochloric acid solution with a mass concentration of 18%, and soak for 5 minutes at 28°C.

[0028] S1.5. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.4 in the hydrochloric acid solution with a mass concentration of ...

Embodiment 2

[0039] Embodiment 2: the invention discloses a steel wire rope pickling method, comprising:

[0040] S1.1. Immerse the steel wire rope in a hydrochloric acid solution with a mass concentration of 8%, and soak for 4 minutes at 30°C.

[0041] S1.2. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.1 in the hydrochloric acid solution with a mass concentration of 11%, and soak for 4 minutes at 30°C.

[0042] S1.3. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.2 into the hydrochloric acid solution with a mass concentration of 14%, and soak for 4 minutes at 30°C.

[0043] S1.4. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.3 into the hydrochloric acid solution with a mass concentration of 17%, and soak for 4 minutes at 30°C.

[0044] S1.5. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.4 into the hydrochloric acid solution with a mass concentration of 21%, and soak for 4 m...

Embodiment 3

[0052] Embodiment 3: the invention discloses a steel wire rope pickling method, comprising:

[0053] S1.1. Immerse the steel wire rope in a hydrochloric acid solution with a mass concentration of 10%, and soak for 6 minutes at 15°C.

[0054] S1.2. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.1 in the hydrochloric acid solution with a mass concentration of 13%, and soak for 6 minutes at 15°C.

[0055] S1.3. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.2 into the hydrochloric acid solution with a mass concentration of 16%, and soak for 6 minutes at 15°C.

[0056]S1.4. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.3 into the hydrochloric acid solution with a mass concentration of 20%, and soak for 6 minutes at 15°C.

[0057] S1.5. Immerse the steel wire rope soaked in the hydrochloric acid solution in S1.4 into the hydrochloric acid solution with a mass concentration of 23%, and soak for 6 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com