Detection control method and device of inner-coating thickness of rotational molding storage tank

A thickness detection and inner cladding technology is applied in the field of online detection and control of the inner cladding thickness of storage tanks, and the detection and control method and device of the inner cladding thickness of rotomolded storage tanks, which can solve the problems of inability to precisely control the uniformity of wall thickness, etc. Achieve the effect of improving labor safety, strong anti-interference and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

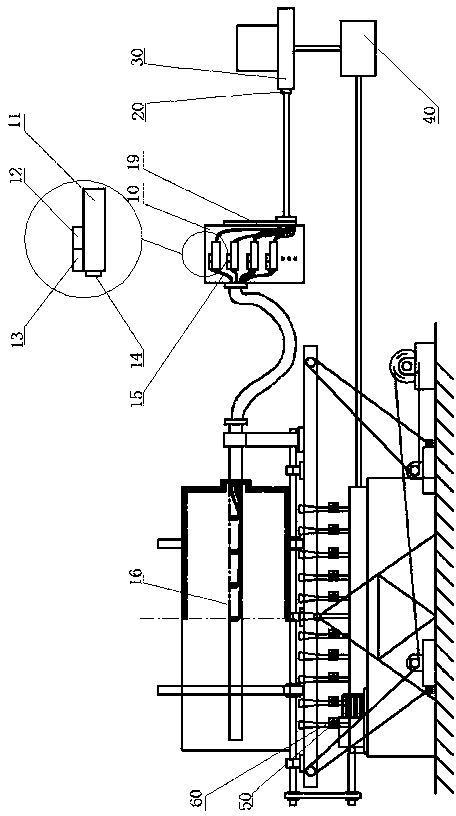

[0040] A method for detecting and controlling the thickness of the inner cladding of a rotomolded storage tank, please refer to figure 1 , 2 , 3. To form 80m 3 (Outer diameter 3350mm, total length 10155mm, barrel length 8490mm, wall thickness 35mm) all-plastic horizontal storage tank, the powder used is linear low-density polyethylene (LLDPE) as an example, and its density is between 0.915 and 0.940 g / cubic centimeter between. The method for detecting and controlling the thickness of the inner cladding layer during the forming process of the storage tank includes the following steps:

[0041] [1] According to the theoretical molding thickness of 35mm and surface area of the storage tank, the mass of material to be added is calculated to be 1833kg. If a bag of LLDPE is 25kg, 69.35 bags are required to put the pre-measured plastic material into the cavity.

[0042] [2] According to the design principle that the body length of the storage tank is 8490mm and that a set of no...

Embodiment 2

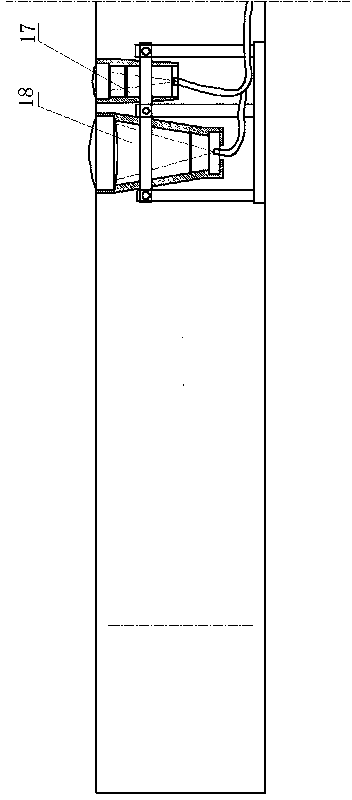

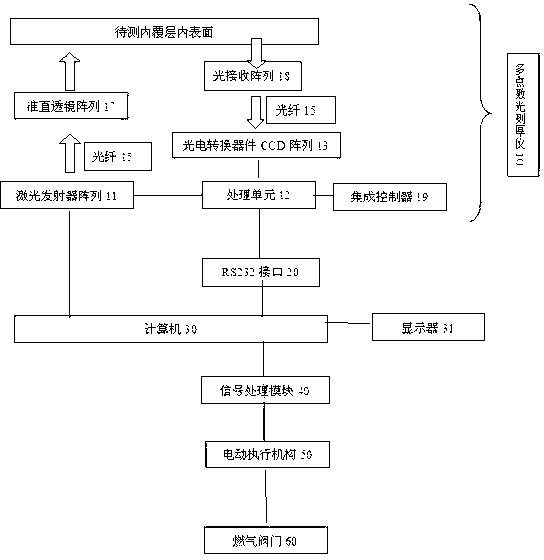

[0056] Such as Figure 1-2 shown.

[0057] A detection and control device for the inner coating thickness of a rotomolded storage tank, especially a multi-point laser thickness measurement device for a revolving body in high-temperature, closed and dynamic processes such as direct-fired rotomolding, including a laser emitter array 11, a photoelectric conversion Device CCD array 13, processing unit array 12, coupling lens 14, optical fiber emitting fiber and receiving optical fiber 15, collimating lens array 17, light receiving array 18, heat insulating sleeve 16, integrated controller 19, RS232 interface 20, computer 30. The input end of the transmitting fiber 15 is connected with the laser transmitter 11 through the coupling lens 14, the output end 14 of the transmitting optical fiber 15 is connected to the collimating lens 17, and the input end of the receiving optical fiber 15 is connected to the optical receiver 18 through the coupling lens 14, and the optical receiver 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com