Cinnamon essential oil-cyclodextrin mixture inclusion compound and preparation method thereof

A technology for mixing cyclodextrin and cinnamon essential oil, applied in the field of medicine, can solve the problems of low solubility, low inclusion rate of cinnamon essential oil, poor stability, etc., and achieves high inclusion rate, easy control of production conditions, and improved inclusion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

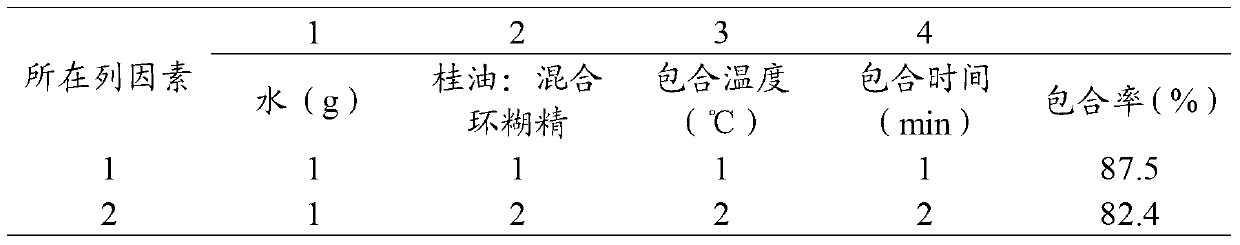

[0016] Example 1: Research on inclusion process of cinnamon essential oil and mixed cyclodextrin

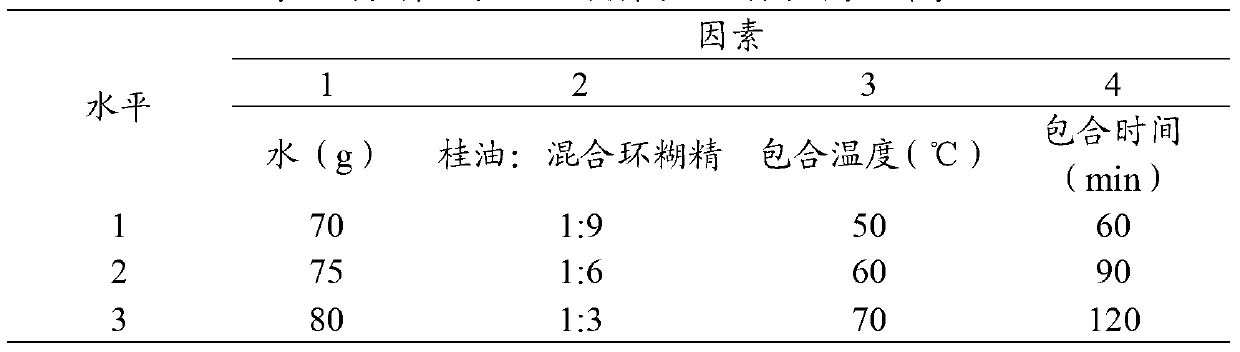

[0017] (1) Determination of the optimal ratio of α-cyclodextrin, β-cyclodextrin and γ-cyclodextrin

[0018] Three different ratios of α-cyclodextrin, β-cyclodextrin and γ-cyclodextrin were selected. After many experiments, the mixed cyclodextrins containing different proportions were packaged at the same temperature and inclusion time. According to the level of inclusion rate, select the best ratio of α-cyclodextrin, β-cyclodextrin and γ-cyclodextrin. The data in Table 1 are obtained through experiments:

[0019] Table 1 Determination table of optimal ratio of α-cyclodextrin, β-cyclodextrin and γ-cyclodextrin

[0020]

[0021] Cyclodextrin cyclodextrin CD for short.

[0022] From the experimental results, it can be seen that when the ratio of α-cyclodextrin, β-cyclodextrin and γ-cyclodextrin is 4:2:1 by weight, the inclusion rate of cinnamon essential oil is the highest.

...

Embodiment 2

[0032] 15 parts of mixed cyclodextrin (the ratio of α-cyclodextrin, β-cyclodextrin and γ-cyclodextrin is 4:2:1), 75 parts of water, heated to 70°C to make mixed cyclodextrin Saturated aqueous solution, cooled to 50°C, add 2 parts of cinnamon essential oil drop by drop, use a shearing machine to carry out clathrate under stirring at 5000r / min, keep the temperature of the system above 50°C, stir for 60 minutes, and check the clathrate by microscope , naturally cooled to room temperature, spray-dried the cinnamon essential oil clathrate solution to obtain the product, and the clathrate rate of the cinnamon essential oil was 92.3%.

Embodiment 3

[0034] 16 parts of mixed cyclodextrin (the ratio of α-cyclodextrin, β-cyclodextrin and γ-cyclodextrin is 4:2:1), 80 parts of water, heated to 70°C to make mixed cyclodextrin Saturated aqueous solution, cooled to 55°C, adding 2 parts of cinnamon essential oil dropwise and stirring with a shearing machine at 5000r / min for clathrate, the temperature of the system was kept above 50°C, stirred for 60 minutes, and the clathrate was checked by microscope. Naturally cool down to room temperature, spray-dry the cinnamon essential oil clathrate solution to obtain the product, and the clathrate rate of the cinnamon essential oil is 92.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com