Sugarcane top crusher

A crusher and sugarcane leaf technology are applied in the field of biomass pellet fuel crushing and processing equipment to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of this sugarcane leaf shredder is described in detail below in conjunction with embodiment and accompanying drawing, but specific embodiment of the present invention is not limited to following embodiment.

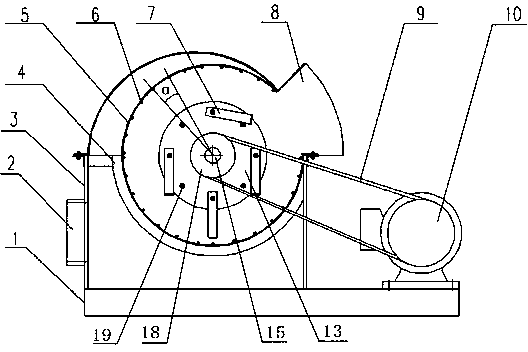

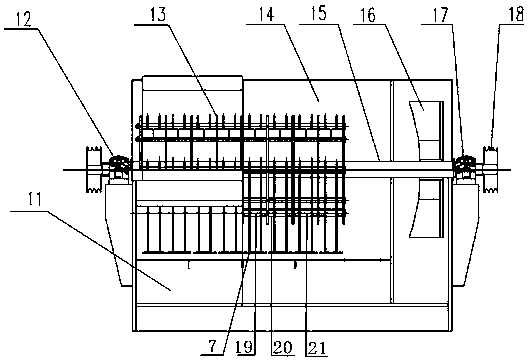

[0014] Such as figure 1 As shown, the motor 10 installed on the base 1 is connected with the pulley 18 through the transmission belt 9, and the pulley 18 is installed on the rotating main shaft 15, and the rotating main shaft 15 is evenly distributed with rotating crushing cutterheads 13, and each rotating crushing cutterhead 13 peripherals are evenly provided with eight holes with a diameter of 20 mm so that the rotary cutter shaft 19 passes through, and the T-shaped rotary cutter 7 is installed on the rotary cutter shaft 19. The net reinforcing plate 4 and the screen 5 are formed, the screen 5 is arc-shaped and evenly provided with a choke bar 6, the inlet 8 and the outlet 2 are respectively at the upper right and lower left of the bin bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com