Oxygen-hydrogen co-production device and method based on chemical chain reaction

A technology of chemical chain and oxygen, applied in the field of chemical chain, can solve the problems of high energy consumption, high energy consumption of hydrogen production, unsuitable for industrial production, etc., and achieve the effects of low energy consumption, reduced production cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

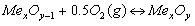

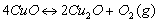

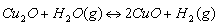

Method used

Image

Examples

Embodiment 1

[0033] (1) Add the copper-based oxygen carrier particles into the oxygen-generating fluidized bed from the feeding port of the oxygen-generating fluidized bed, control the temperature of the oxygen-generating fluidized bed in the oxygen-generating fluidized bed to 1100°C, and Deoxygenation reaction and release of oxygen;

[0034] Open the flow control device of the carrier gas inlet of the oxygen-producing fluidized bed, and pass in the pure oxygen carrier gas. The ratio of the carrier gas flow rate to the oxygen flow rate released by the reaction is controlled at 5:1. The final oxygen carrier particles also enter the oxygen generation cyclone separator, and the gas-solid separation is carried out in the oxygen generation cyclone separator. The carrier gas and oxygen enter the oxygen storage cabinet through the upper exhaust port of the oxygen generation cyclone separator. Oxygen particles enter the feed port of the hydrogen production fluidized bed through the lower part of t...

Embodiment 2

[0045] (1) Add the cobalt-based oxygen carrier particles into the oxygen-generating fluidized bed from the feeding port of the oxygen-generating fluidized bed, control the temperature of the oxygen-generating reactor in the oxygen-generating fluidized bed to 800°C, and Deoxygenation reaction and release of oxygen;

[0046] Open the flow control device of the carrier gas inlet of the oxygen-producing fluidized bed, and pass in the carbon dioxide carrier gas. The ratio of the carrier gas flow rate to the oxygen flow rate released by the reaction is controlled at 3:1. The oxygen is brought into the oxygen-producing cyclone separator by the carrier gas. After deoxygenation The oxygen carrier particles also enter the oxygen generation cyclone separator, and the gas-solid separation is carried out in the oxygen generation cyclone separator. The carrier gas and oxygen enter the oxygen storage cabinet through the upper exhaust port of the oxygen generation cyclone separator. The solid...

Embodiment 3

[0052] (1) Add manganese-based oxygen carrier particles into the oxygen-generating fluidized bed from the feed / feed port of the oxygen-generating fluidized bed, control the temperature of the oxygen-generating fluidized bed in the oxygen-generating fluidized bed to 500°C, and Deoxygenation reaction and release of oxygen;

[0053] Open the flow control device of the carrier gas inlet of the oxygen production fluidized bed, and introduce industrial flue gas rich in carbon dioxide as the carrier gas. The ratio of the flow rate of the carrier gas to the oxygen flow rate released by the reaction is controlled at 1:1, and the oxygen is brought into the oxygen production by the carrier gas. In the cyclone separator, the deoxygenated oxygen carrier particles also enter the oxygen generation cyclone separator, and the gas-solid separation is carried out in the oxygen generation cyclone separator, and the carrier gas and oxygen enter the oxygen storage cabinet through the upper exhaust p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com