Halogen-free flame-retardant casing material for protecting automotive rubber tube

An automotive rubber hose and sleeve technology, applied in the field of sleeves, can solve the problems of poor flame retardant performance, easy to wrinkle, contain halogens, etc., and achieve solvent resistance and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

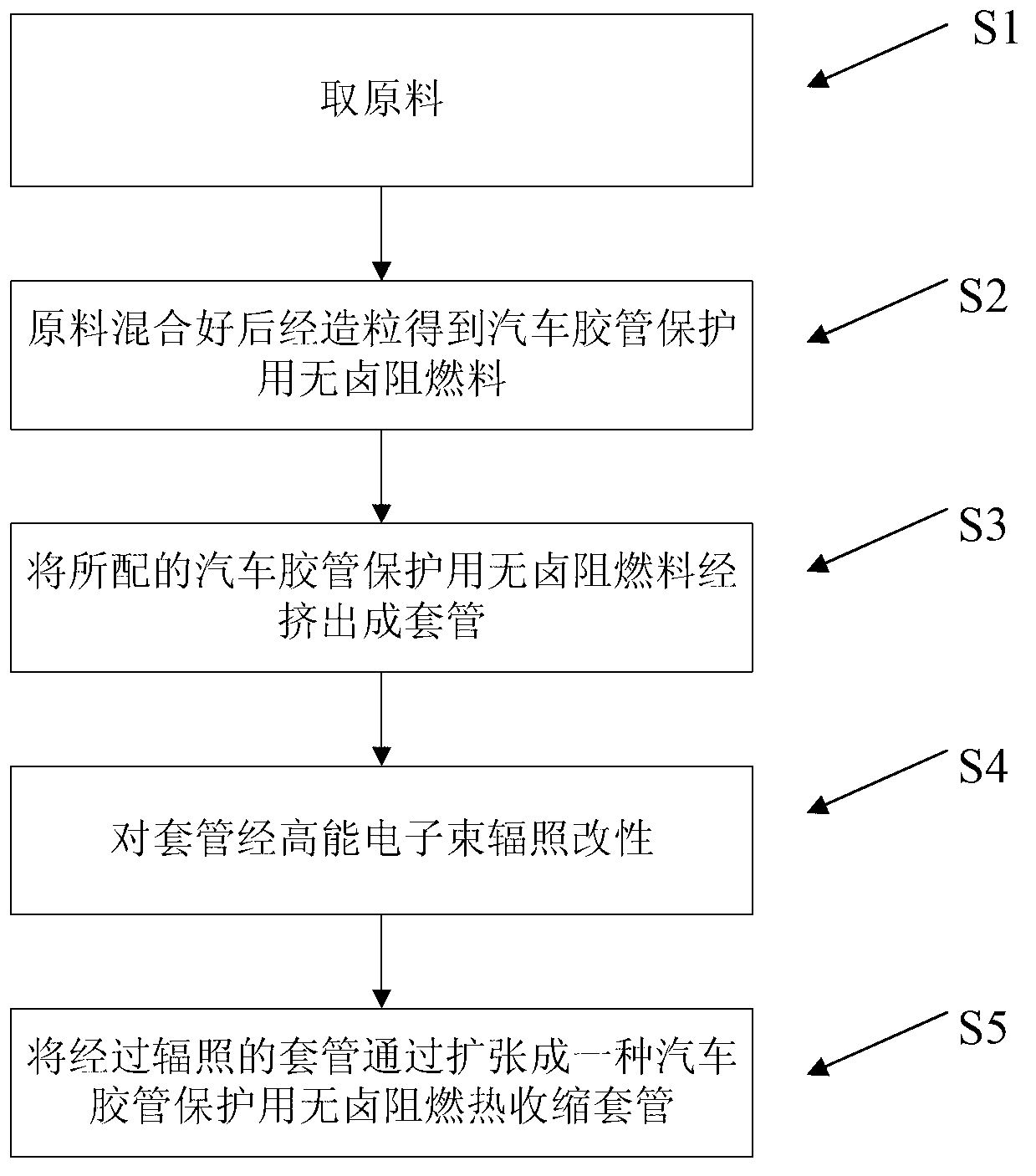

Method used

Image

Examples

Embodiment

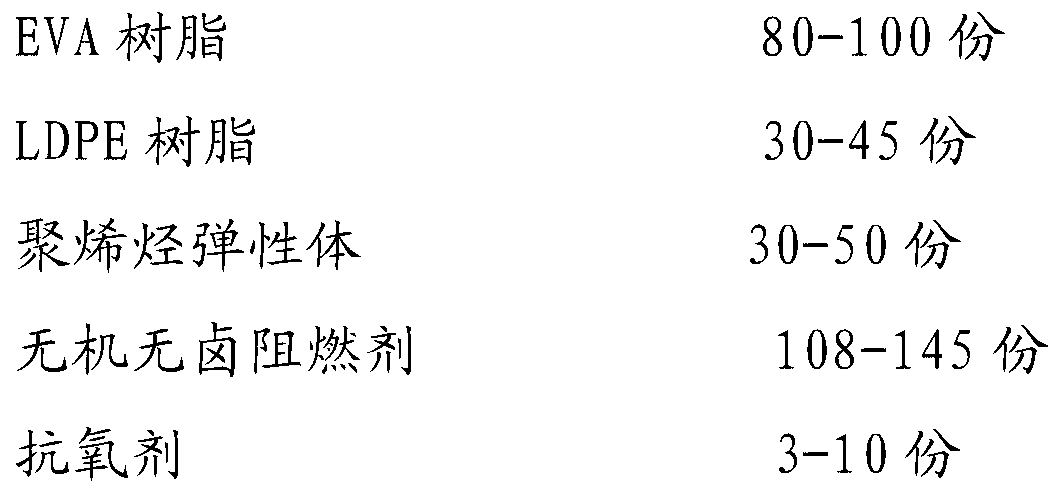

[0033] Take 100 kg of EVA resin, 40 kg of LDPE resin, 40 kg of polyolefin elastomer, 110 kg of aluminum hydroxide 250 mesh, 10 kg of red phosphorus, 5 kg of tetraerythritol ester (antioxidant), and 5 kg of silane (coupling agent) 5 kg of color masterbatch mixed and granulated to obtain halogen-free retardant fuel for automobile rubber hose protection. It is extruded into a tubular shape by equipment to obtain a halogen-free flame-retardant sleeve for automobile rubber hose protection; it is modified by high-energy electron beam radiation; and finally expanded by an expansion machine to obtain a halogen-free flame-retardant heat-shrinkable sleeve for automobile rubber hose protection. The inner diameter before shrinkage is 30mm, and the wall thickness before shrinkage is 0.5mm. The inner diameter after shrinkage is 15mm, and the wall thickness after shrinkage is 1.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com