Chemical fixing agent for heavy metal contaminated soil remediation and preparation and application thereof

A contaminated soil and chemical immobilization technology, which is applied in the restoration of polluted soil, chemical instruments and methods, and compositions for inhibiting chemical changes, can solve the problems of low heavy metal immobilization efficiency, easy re-release of heavy metals, and secondary pollution. Achieve the effect of low cost, wide source of raw materials, and strengthening the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

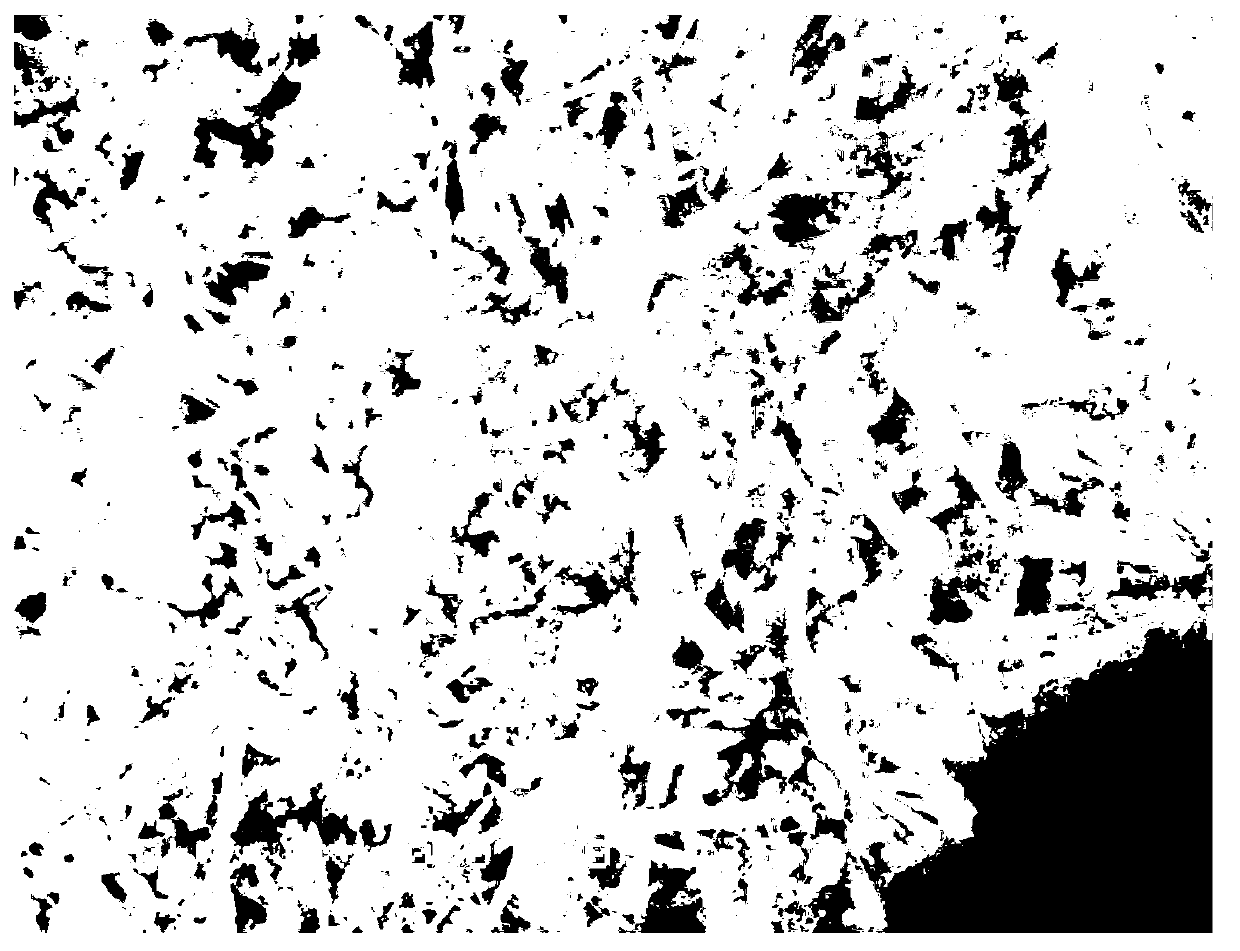

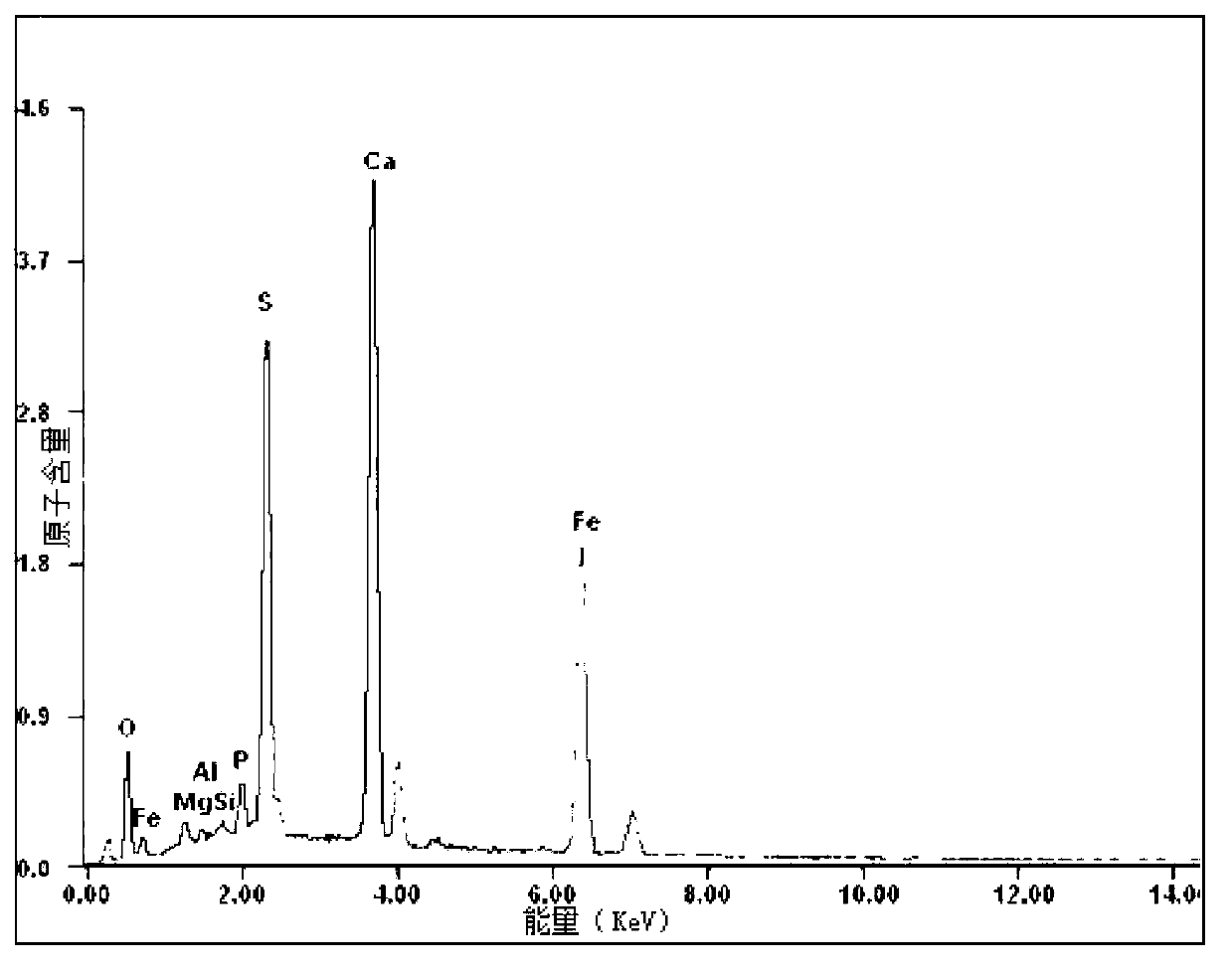

Image

Examples

Embodiment 1

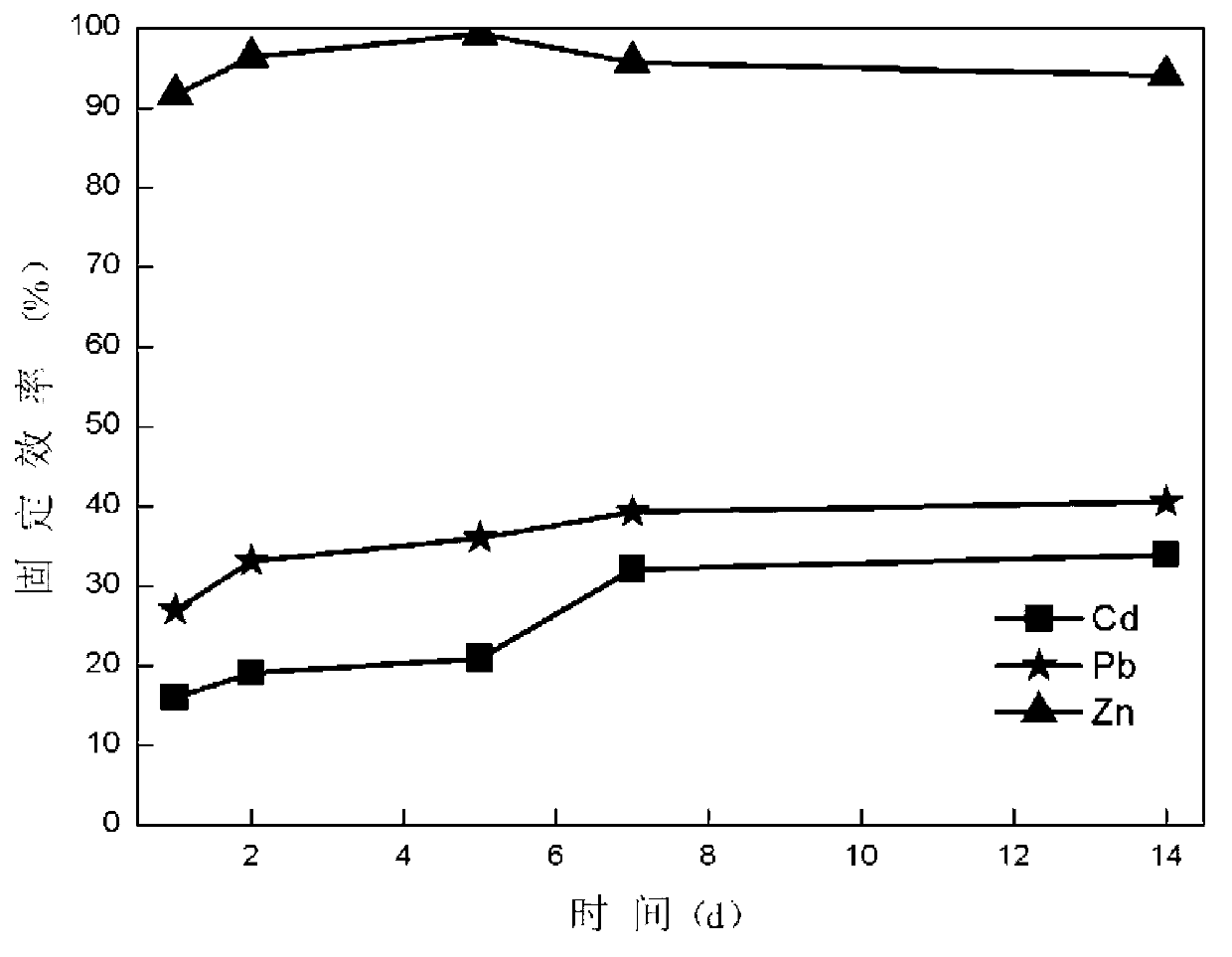

[0028] Dissolve titanium dioxide waste slag in water, and measure its Fe by titration 2+ content, and formulated to 0.3mol L -1 FeSO 4 solution, add Ca(H 2 PO 4 ) 2 powder, stir until completely dissolved; add carbide slag supernatant to the above mixed solution while stirring, adjust the pH of the mixed solution to 7.02; then add the molar ratio of H 2 o 2 : Fe 2+ =1.2:1 Add hydrogen peroxide, react for 90 minutes, vacuum filter, and dry the resulting filter residue in a constant temperature oven at 60°C to constant weight, crush it and pass it through a 20-mesh sieve to prepare a soil heavy metal fixative. Weigh 100g of lead and cadmium contaminated soil, add 5g of the above-mentioned fixative, add tap water according to the soil-water mass ratio of 3:1, and stir until uniform. Samples were taken at 1, 2, 5, 7, and 14 days respectively, and the available Cd, Pb, and Zn contents in the soil (DTPA extraction dosage state) were determined. After testing, the soil availa...

Embodiment 2

[0030] Dissolve titanium dioxide waste slag in water, and measure its Fe by titration 2+ content, and formulated to 0.3mol L -1 FeSO 4 solution, add phosphoric acid to the above solution at a molar ratio of P / Fe=0.08, and stir until completely dissolved; add carbide slag supernatant to the above mixture while stirring, and adjust the pH of the mixture to 8.45; Molby H 2 o 2 : Fe 2+ =1.5:1 Add hydrogen peroxide, oxidize for 120 minutes, vacuum filter, and dry the resulting filter residue in a constant temperature oven at 70°C to constant weight, crush it and pass it through a 20-mesh sieve to prepare a soil heavy metal fixative.

[0031] Weigh 100g of lead and cadmium contaminated soil, add 5g of the above-mentioned fixative, add tap water according to the soil-water mass ratio of 3:1, and stir until uniform. Samples were taken at 1, 2, 5, 7, and 14 days respectively, and the available Cd, Pb, and Zn contents in the soil (DTPA extraction dosage state) were determined. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com