Laser remelting one-step reinforcing processing method and device thereof for plasma sprayed thermal barrier coating with double-layer structure

A double-layer structure, thermal barrier coating technology, applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems of complicated process and easy cracks in the coating, and achieve simple process and remelting coating High layer quality and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

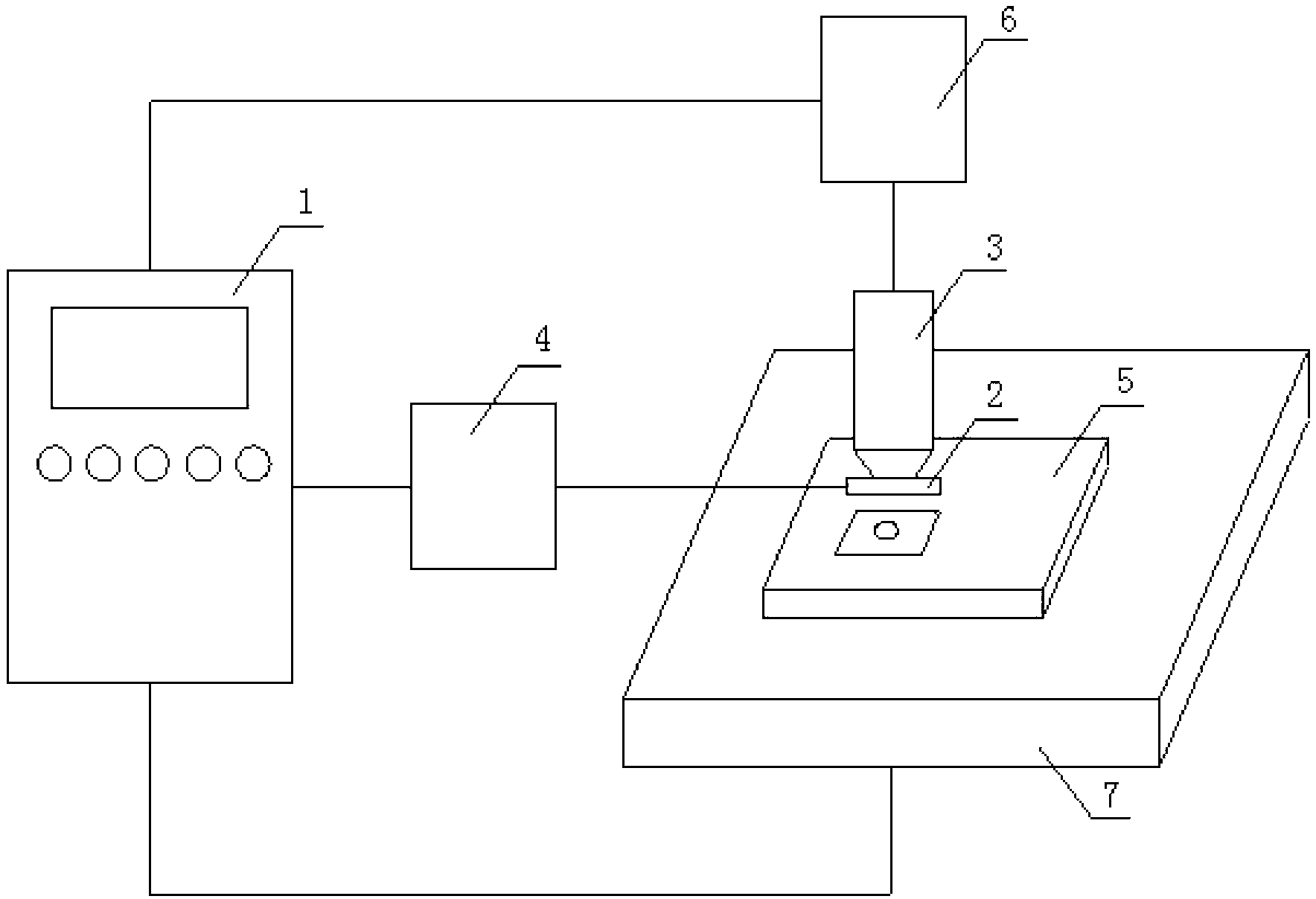

[0023] like figure 1 As shown, the processing device of the present invention includes an induction heating coil 2, a laser head 3, and a high-frequency induction heater 4. The high-frequency induction heater 4 is connected to the induction heating coil 2, and the induction heating coil 2 is fixed on the laser head 3. Above, the laser emitted by the laser head 3 is located in the center of the heating area of the induction heating coil 2, and the sample 5 is fixed on the workbench 7. This device also uses the numerical control console 1 to control the laser 6 and the high-frequency induction heater 4 respectively, and the laser 6 It is connected with the laser head 3.

[0024] One-step enhanced plasma spraying of MCrAlY / ZrO on the surface of nickel-based superalloy substrate using induction heating assisted laser remelting composite process 2 Double-layer structure thermal barrier coating, the specific steps are as follows:

[0025] (1) The surface of the GH4033 nickel-bas...

Embodiment 2

[0029] In this example, the induction heating-assisted laser remelting composite process is used to intensify the plasma spraying of MCrAlY / ZrO on the surface of the nickel-based superalloy substrate in one step. 2 -MgO double-layer structure thermal barrier coating, the specific steps are as follows:

[0030] (1) The surface of the GH4033 nickel-based superalloy substrate is pretreated by grinding, degreasing, sandblasting and cleaning;

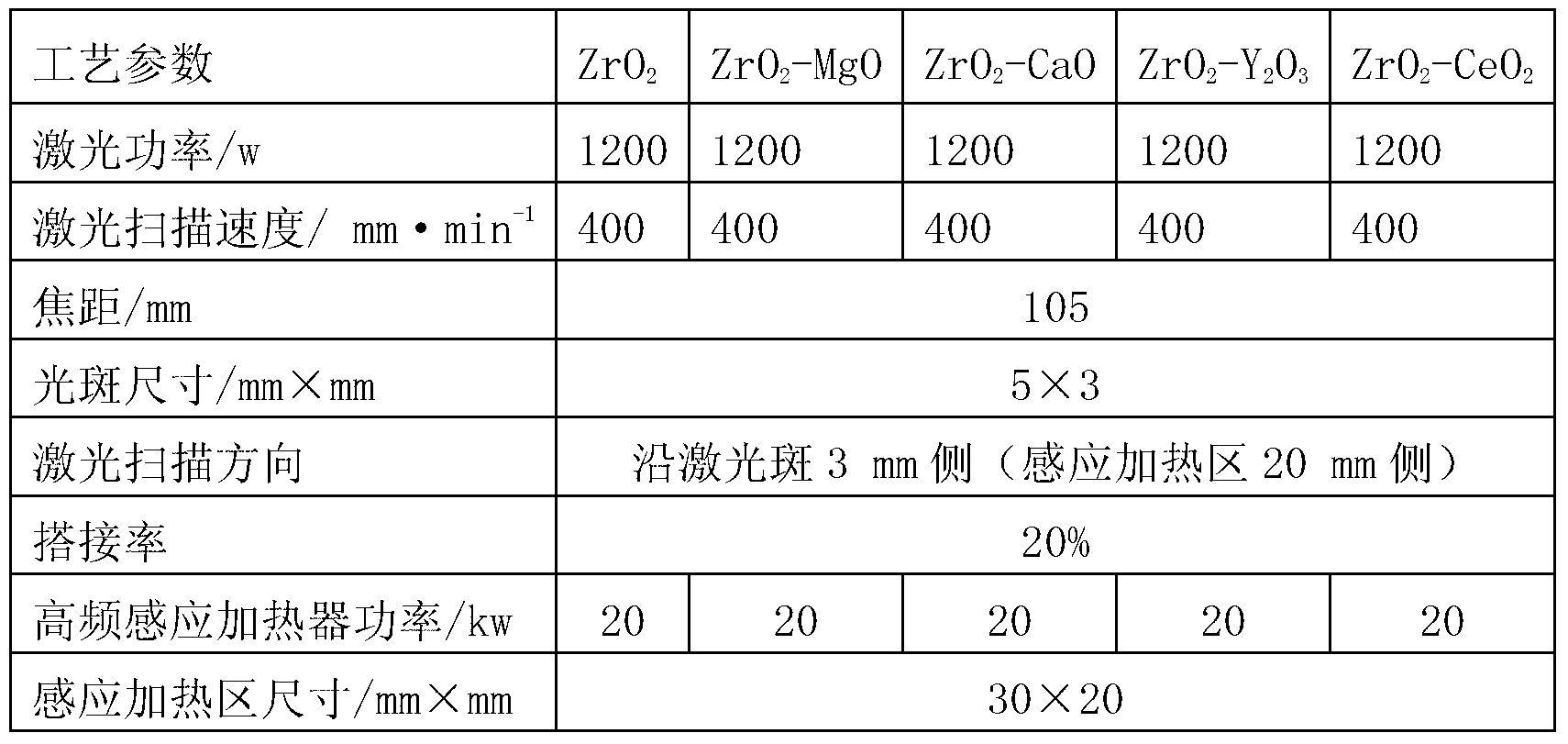

[0031] (2) Spray MCrAlY metal bonding layer and ZrO on the surface of nickel-based superalloy substrate in sequence 2 -22%MgO (mass fraction) surface ceramic layer, spraying process parameters are shown in Table 1;

[0032] (3) Through laser remelting treatment, the ZrO in the double-layer structure thermal barrier coating 2 The -22%MgO surface ceramic layer and the MCrAlY metal bonding layer are melted at the same time, so that the ZrO 2 The interface between the -22%MgO surface ceramic layer and the MCrAlY metal bonding layer, and the i...

Embodiment 3

[0035] In this example, the induction heating-assisted laser remelting composite process is used to intensify the plasma spraying of MCrAlY / ZrO on the surface of the nickel-based superalloy substrate in one step. 2 -CaO double-layer structure thermal barrier coating, the specific steps are as follows:

[0036](1) The surface of the GH4033 nickel-based superalloy substrate is pretreated by grinding, degreasing, sandblasting and cleaning;

[0037] (2) Spray MCrAlY metal bonding layer and ZrO on the surface of nickel-based superalloy substrate in sequence 2 -15%CaO (mass fraction) surface ceramic layer, spraying process parameters are shown in Table 1;

[0038] (3) Through laser remelting treatment, the ZrO in the double-layer structure thermal barrier coating 2 The -22%MgO surface ceramic layer and the MCrAlY metal bonding layer are melted at the same time, so that the ZrO 2 -15%CaO surface ceramic layer and MCrAlY metal bonding layer interface, MCrAlY metal bonding layer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com