Technology for realizing solid burying maximization and residual oil displacement by supercritically injecting CO2 (carbon dioxide) excessively into oil well

An over-injection and supercritical technology, which is applied to other gas emission reduction technologies, wellbore/well components, production fluids, etc., can solve the problems of narrow displacement residual oil area, high cost, and small area, so as to improve oil well resources Effects of utilization rate, stable storage status, and mature application technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

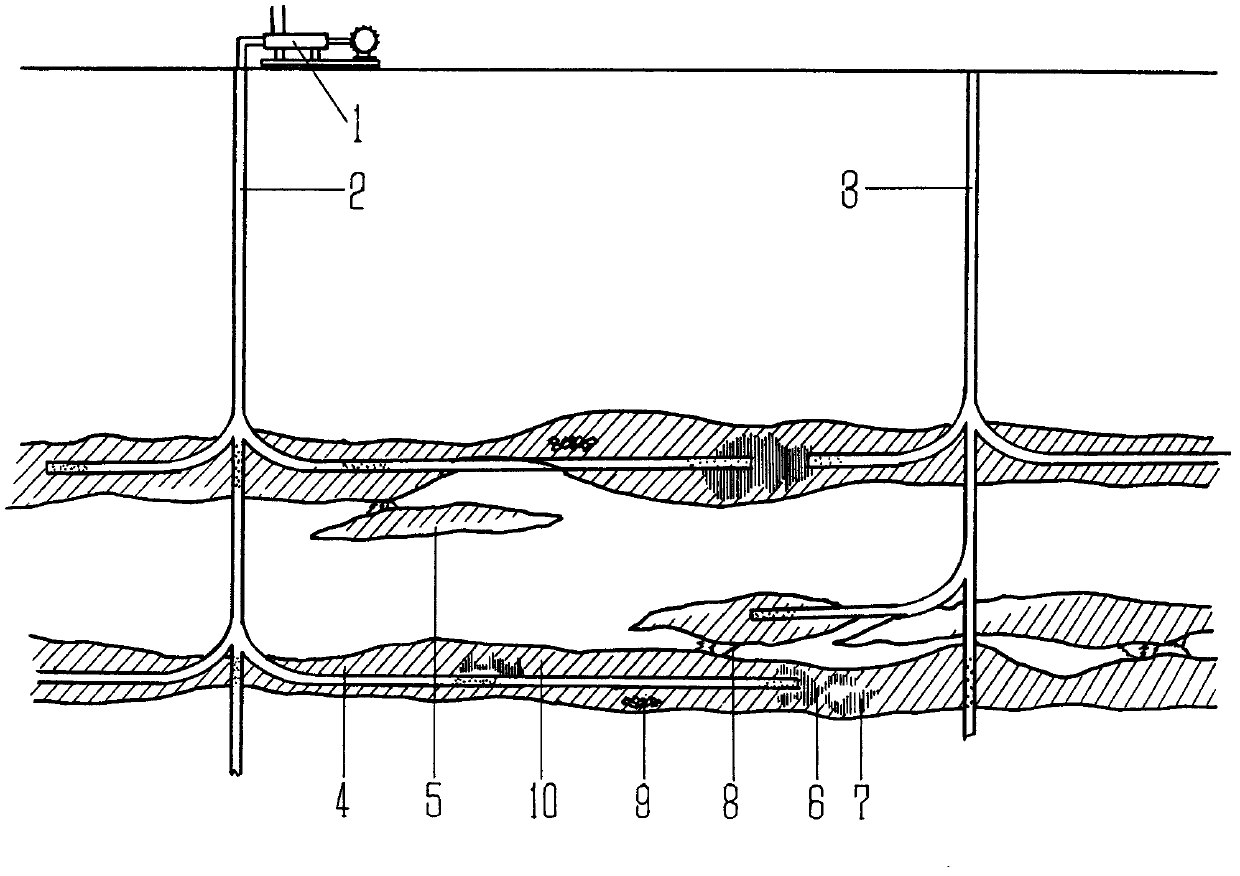

[0014] Below in conjunction with accompanying drawing of description, to oil well supercritical excessive injection of CO of the present invention 2 To achieve the maximum embedding and residual oil displacement technology in further detail:

[0015] Such as figure 1 , shown, abandoned, old oil fields or oil areas, choose to determine the CO 2 In the cementing area, check the archives, re-examine if necessary, select the injection well 2 and the oil output well 3 according to the ratio of 1:3-10, carry out workover operations until they are in good condition, drill new wells if necessary, and install them at the head of the injection well 2 High-pressure air pump 1, infusing CO into the oil layer 4 at supercritical pressure 2 . When there is no obvious pressure change, or the pressure does not rise but falls, the oil well 3 discharges oil and CO 2 When the ratio reaches the set standard, CO is injected into the injection well 2 2 Add a plugging agent to block the smooth c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com