Cavity ring-down fiber grating sensing demodulating device based on calibrated fiber grating

A technology for calibrating optical fibers and fiber gratings, applied in light demodulation, using optical devices to transmit sensing components, optics, etc., can solve problems such as system performance limited by environmental factors, limited light source wavelength, drift, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

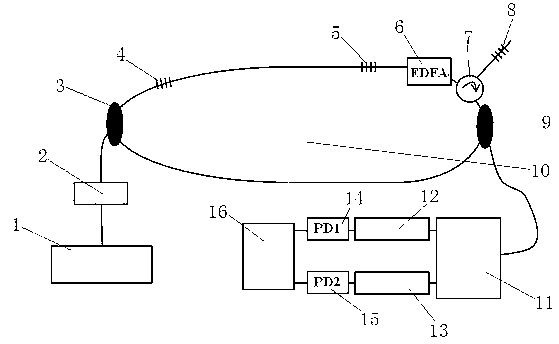

[0014] Such as figure 1 As shown, the present invention is realized in this way, it comprises dual-wavelength tunable narrow-linewidth laser 1, optical switch 2, optical coupler I 3, calibration fiber grating 4, sensing fiber grating 5, erbium-doped fiber amplifier 6, light ring shaper 7, denoising fiber grating 8, optical coupler II9, fiber ring cavity 10, optical coupler III11, optical filter I12, optical filter II13, photodetector I14, photodetector II15 and signal processor 16, Its structural feature is that an optical switch 2 is connected between the dual-wavelength tunable narrow-linewidth laser 1 and the optical coupler I3, and the optical fiber ring cavity 10 is sequentially connected with the optical coupler I3, the calibration fiber Bragg grating 4, and the sensing fiber Bragg grating 5 in a clockwise direction. , erbium-doped fiber amplifier 6, optical circulator 7 and optical coupler Ⅱ 9, optical circulator 7 is also connected with denoising fiber grating 8, optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com