Box-packed nano beancurd making method and beancurd product thereof

A production method and tofu technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of complex production process of nano-tofu, inability to adapt to cooking techniques, poor molding effect, etc., and achieve obvious economic and social benefits. Good molding effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

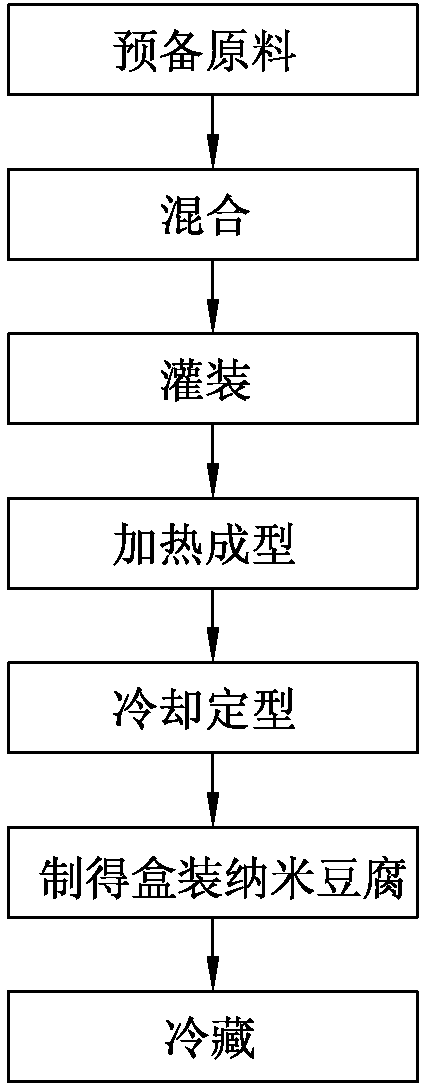

[0030] Embodiment 1: see figure 1 , a method for making boxed nano tofu, comprising the following steps.

[0031] (1) Prepare raw materials: The raw materials include the following components in weight percentage: 93% of soybean milk, 0.32% of composite coagulant, and 6.68% of composite improver, wherein the particle size of the particles in soybean milk is 3-50um.

[0032] (2) Mixing: Cool down the soybean milk until below 30°C, then move the soybean milk to the batching tank, then add the composite coagulant and composite quality improver, and stir evenly.

[0033] (3) Filling: Move the prepared soybean milk to the high-level tank. The bottom of the high-level tank is provided with a slurry outlet nozzle. The soybean milk undergoes natural defoaming, and the soybean milk flows into the small storage tank on the filling and sealing machine under the action of the high-level difference. , and then fill it.

[0034] (4) Thermoforming: transfer the filled product to a thermofo...

Embodiment 2

[0049] Example 2, the boxed nano-tofu production method provided in this example and the tofu products implementing the above-mentioned boxed nano-tofu production method, its preparation steps and components are basically the same as in Example 1, the difference is that its raw materials The composition includes the following components by weight percentage: 98% of soybean milk, 0.28% of composite coagulant, and 1.72% of composite improver, wherein the particle size of the particles in the soybean milk is 3-50um.

Embodiment 3

[0050] Example 3, the boxed nano-tofu production method provided in this example and the tofu products implementing the above-mentioned boxed nano-tofu production method, its preparation steps and components are basically the same as in Example 1, the difference is that its raw materials The composition includes the following components by weight percentage: 96.7% of soybean milk, 0.3% of composite coagulant, and 3% of composite improver, wherein the particle size of the particles in the soybean milk is 3-50um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com