Energy-saving method and device for controlling moisture discharging of roller-type cut-tobacco dryer

A control method and technology of a silk drying machine, which are applied in the fields of tobacco preparation, application, and tobacco, can solve the problems of difficulty in determining the tidal volume, large fluctuation of pressure at the measuring point, poor control quality, etc., so as to reduce steam consumption, The effect of reducing operating power and heat output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

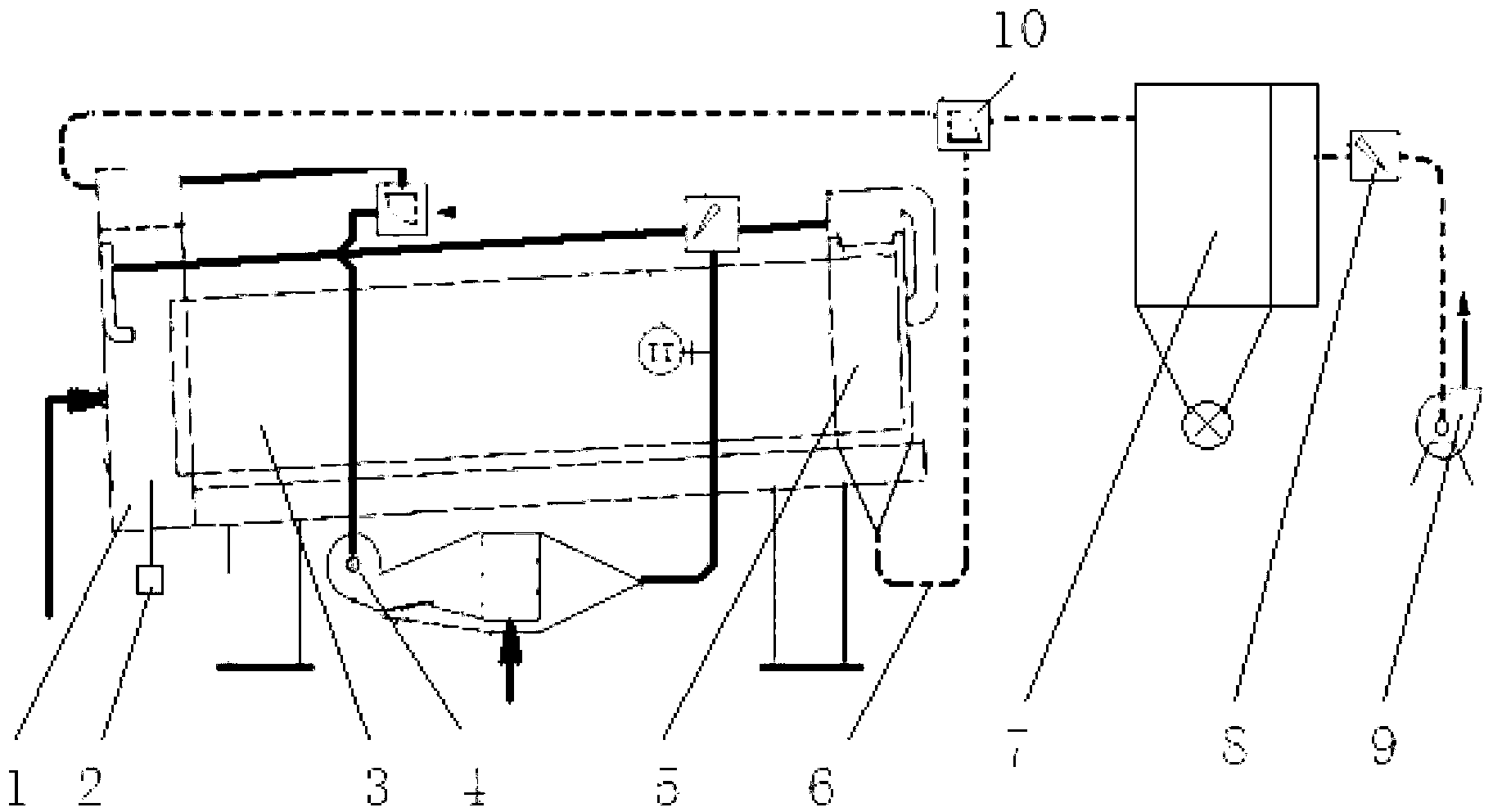

[0027] The pressure sensor 2 is arranged in the back room 1 of the silk drying machine, and the moisture is discharged in the back room 1 or the front room 5 through the moisture conversion valve 10, and the discharged moisture is sequentially passed through the configured bag filter 7, the damper 8 and Tidal blower fan 9 is discharged outdoors. The pressure sensor 2, the damper 8 and the hot air fan 4 are all connected to the control system, and the air pressure P (1Pa) controlled by the pressure sensor 2 measuring point in the working room is set in the control system, and the tolerance P1 (0.5Pa) of the air pressure is set, and the hot air fan is set. 4 The rotational speeds in the working and idle states are respectively Q1 (50%) and Q2 (30%), and the adjustment amount Q3 (2%) and the adjustment time t (10S) of the damper 8 are set each time.

[0028] When the tidal exhaust blower 9 is started, the damper 8 is in a closed state to reduce the starting load of the tidal exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com