Cleaning method of substrates

A substrate and cleaning agent technology, applied in the field of cleaning, can solve problems such as induced product defects, difficulty in removing small foreign matter on the substrate surface, and low product yield, and achieve the effects of increasing molecular activity, improving yield, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

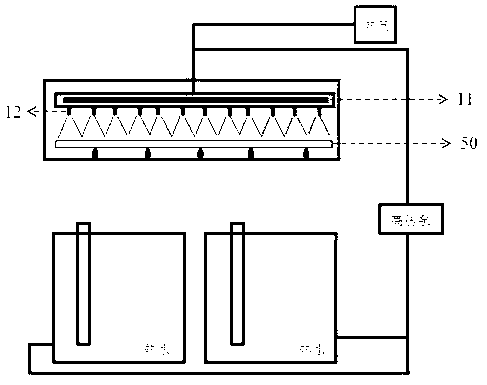

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

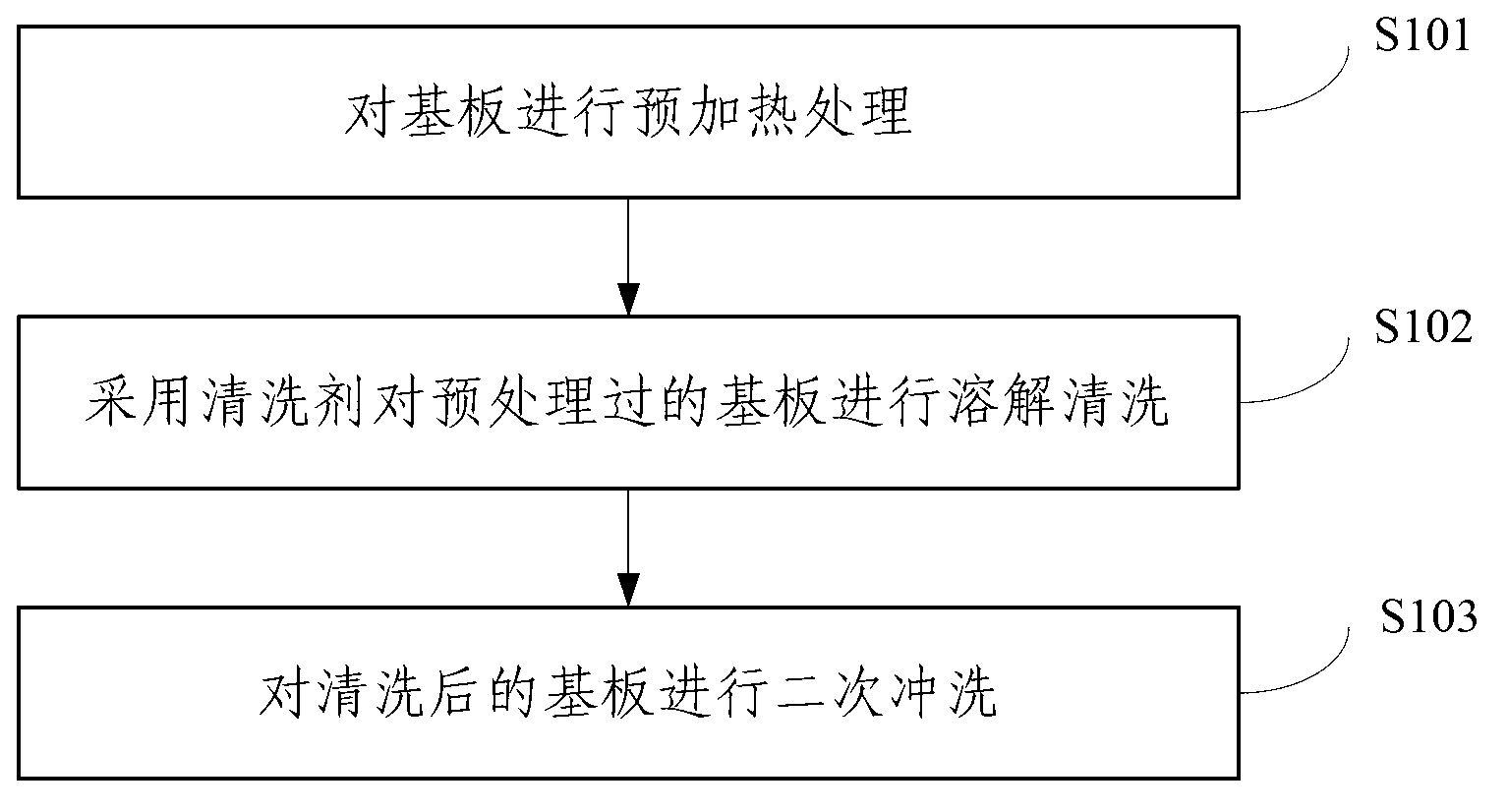

[0032] Such as figure 1 As shown, the substrate cleaning method provided in this embodiment specifically includes the following steps:

[0033] Step S101 , preheating the substrate.

[0034] Specifically, a heat source such as a hot gas source, a hot water source, or an infrared heat source is used to heat the substrate. The heating temperature of the hot water source is 80-100° C., and the heating temperature of the substrate using a hot air source or an infrared heat source can be 100-120° C.

[0035] The preheating temperature of the substrate is 25-120°C, preferably, the substrate is preheated to 40-120°C, more preferably, the substrate is preheated to 100-120°C. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com