TiZr base amorphous alloy with low Cu and Ni contents and preparation method thereof

A technology of amorphous alloy and brazing filler metal, which is applied in the field of TiZr-based amorphous alloy brazing filler metal with low Cu and Ni content and its preparation field, and can solve the problem of poor processing performance of titanium-based alloy brazing filler metal, limitation of the use form of brazing filler metal, and brazing joints. performance reduction and other problems, to achieve the effects of excellent toughness and surface quality, improved mechanical properties, and lower melting point of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Composition (mass percentage): Ti38.40%, Zr39.50%, Cu8.15%, Ni3.77%, Co2.84%, Fe1.79%, Al1.30%, Sn3.81%, Si0.44% , namely Ti 50 Zr 27 Cu 8 Ni 4 co 3 Fe 2 al 3 sn 2 Si 1 (atomic percent).

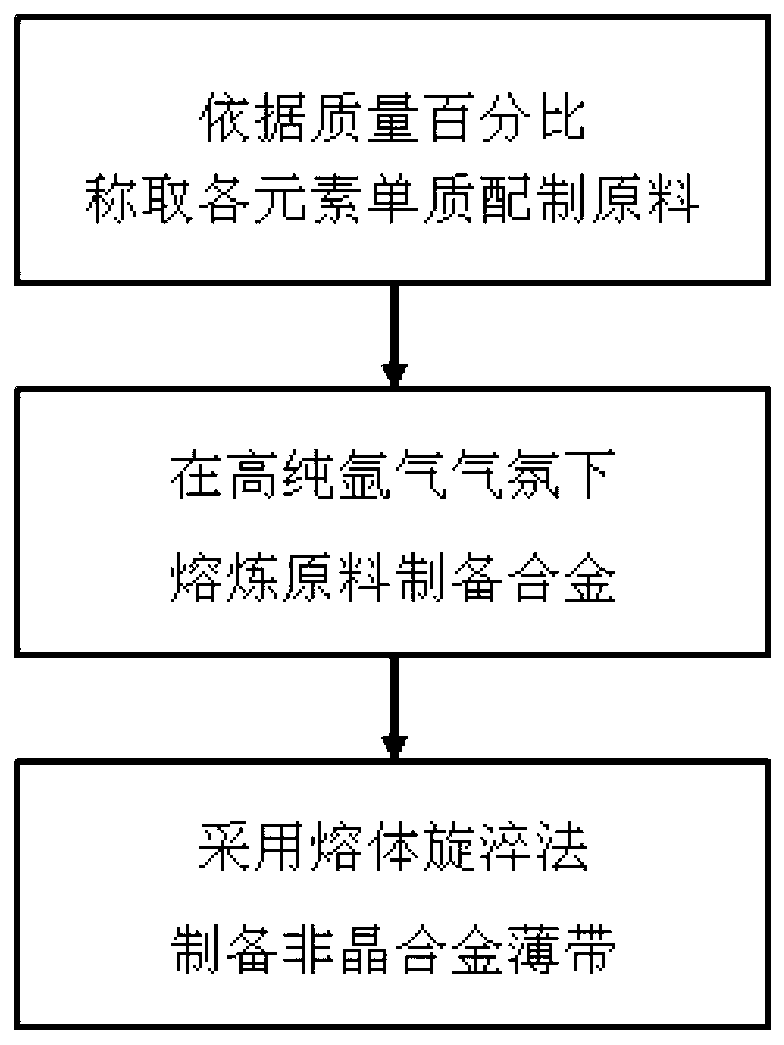

[0037] Preparation:

[0038] (1) Weighing the elemental quality of each element: Weighing the elemental metal raw material of corresponding quality according to the mass percentage;

[0039] (2) Preparation of alloy by smelting: place the metal elemental raw material weighed in step (1) in the arc smelting equipment, and vacuumize until the vacuum degree is 5×10 -3 Pa, filled with high-purity Ar gas, smelting the alloy 4 times by means of arc heating, and taking it out from the smelting equipment after the alloy is cooled with the furnace to obtain the alloy;

[0040] (3) Melt spin quenching method to prepare amorphous alloy thin strips: the alloy prepared in step (2) is broken into small pieces by mechanical crushing, and then placed in a quartz tube with an outlet width of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com