Production process for extra-large aperture super wall thickness square steel pipe

A square steel pipe and production process technology, which is applied to the production process of extra-large-diameter and ultra-thick-wall square steel pipes, can solve the problems of increased defects and influences, low work efficiency, and a large degree of influence on mechanical properties, so as to improve performance strength and save electric energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further elaborate the technical means and effects that the present invention adopts to achieve the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows :

[0038] A production process of super-large-diameter and super-thick square steel pipes is to use a steel plate billet with a specified thickness and length that is commensurate with the size of the final product. Submerged arc welding, final straightening and shaping to form the final super-large-diameter ultra-thick square steel pipe that is not affected by the restrictions of the base material and the width of the material.

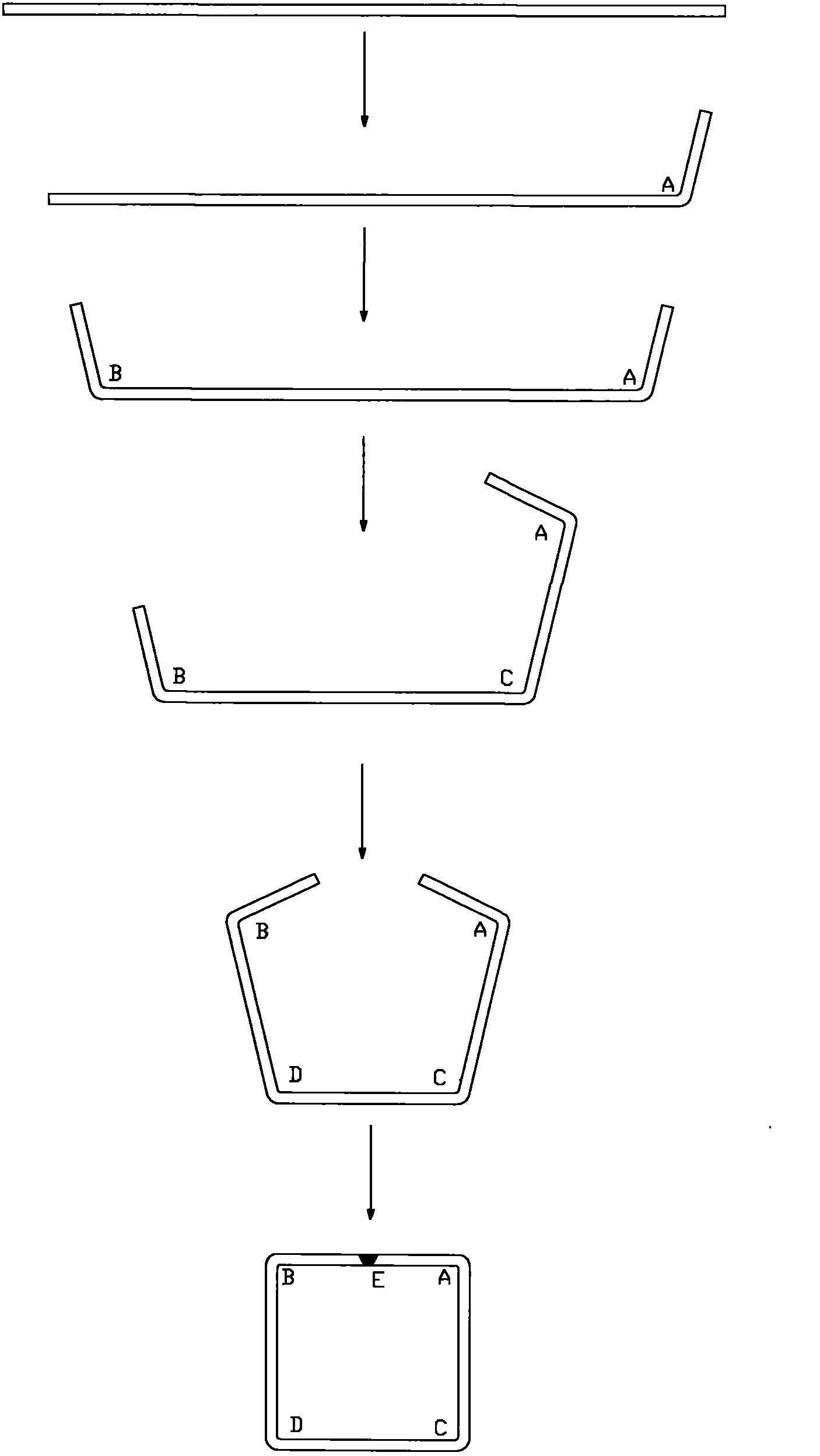

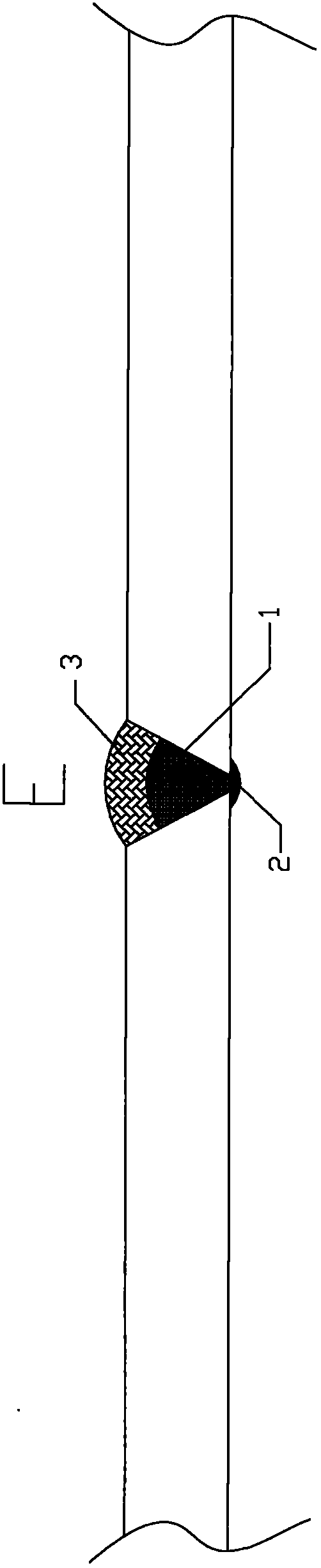

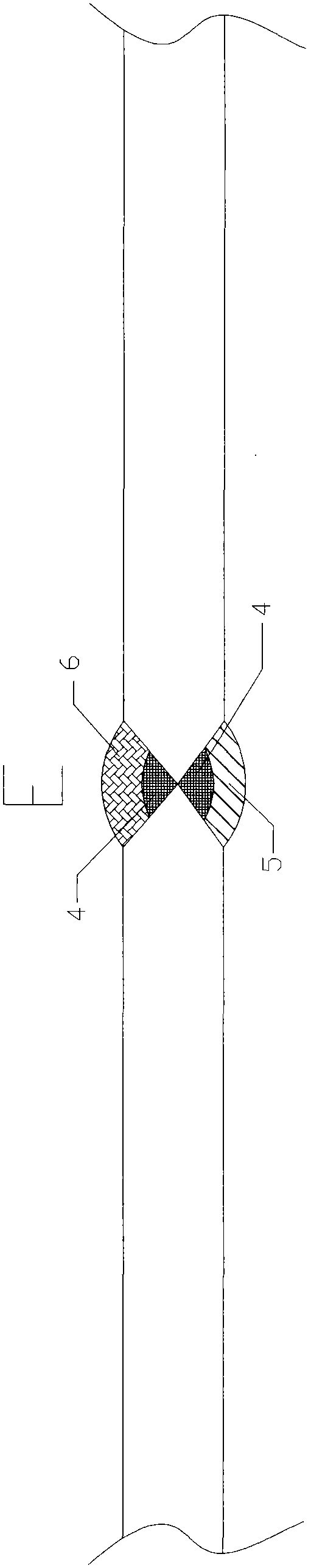

[0039] Such as figure 1 Shown:

[0040] (1) Select a flat steel blank with specified thickness and length commensurate with the size of the final product;

[0041] (2) The steel flat billet passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com