Surface smoothing and modification system for ceramic balls

A ceramic ball and mounting base technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve problems such as the inability to meet process requirements, reduce manual operation errors and human resources, compact body, spherical shape high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

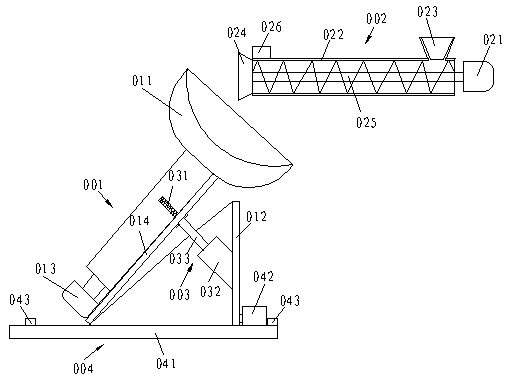

[0013] A system for polishing and modifying the surface of ceramic balls, comprising a sugar coating machine 001 for rolling ceramic balls and an automatic feeding device 002. The sugar coating machine 001 includes a pot mouth 011, a mounting base 012, a motor 013 that drives the pot mouth to rotate, and an inclined fixed The pot mouth 011 is installed on the bracket 014 on the base 012; the automatic feeding device 002 is composed of a motor 021, a conveying pipeline 022, and a feeding port 023 and a feeding port 024 arranged at the two ends of the conveying pipeline 022, and the conveying pipeline 022 is provided with a screw The conveying shaft 025 and the extended end of the screw conveying shaft 025 are connected to the motor 021, and the feeding port 024 is provided with a vibrating feeding device 026, which is a pulse vibrating machine. The feeding opening 024 is set corresponding to the pot mouth 011 of the sugar coating machine 001, the bottom end of the support 014 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com