Compacting method for improving cutting width precision of plastic materials, and device for implementing compacting method

A technology of cutting width and material, applied in the direction of metal processing, etc., can solve the problems of large deformation of material, unable to reach the cutting width, low sensitivity, etc., to avoid frequent fluctuations, reduce raw material loss, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

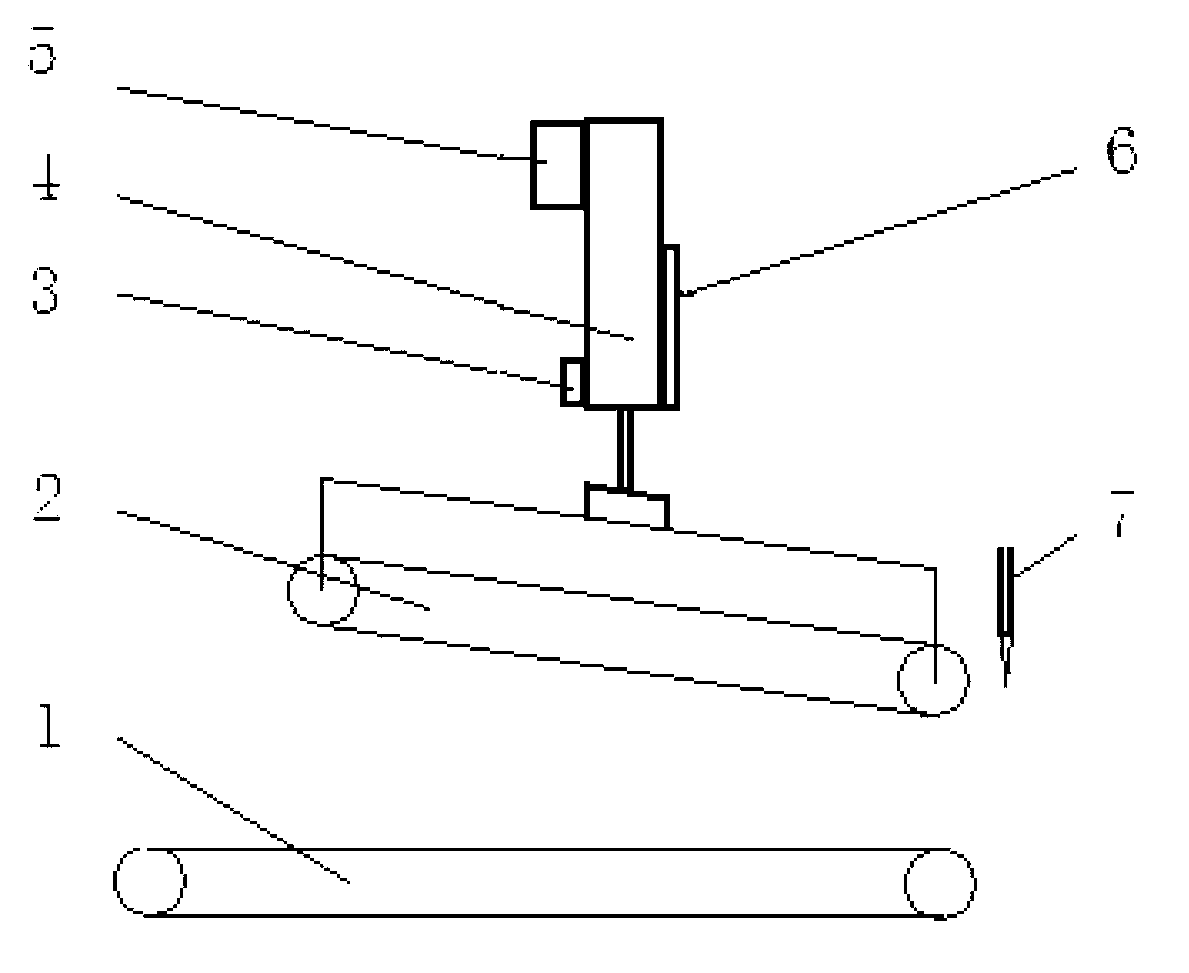

Image

Examples

Embodiment 1

[0019] Install this device on the wire cutter of the test line, the wire cutters L1 and L2 are 50 mm and 80 mm respectively, and the initial height L4 of the wire cutter is 60 mm. By adjusting the material layer height L3 to 2 mm each time, the pressure P1 , P2 are controlled at 1000 kg and 900 kg respectively. Through the experiment, the uniformity of cutting width of the material is increased from 2 sigma to 3 sigma, and the product qualification rate is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com