Wood degreasing, deoiling and drying integrated process

A technology of degreasing and degreasing wood, which is applied in the direction of wood processing equipment, wood treatment, wood treatment details, etc., can solve the problems of consuming chemical raw materials, polluting water, gas and wood slag, and taking a long time, so as to maintain natural color and luster, Short production time and reduced longitudinal cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

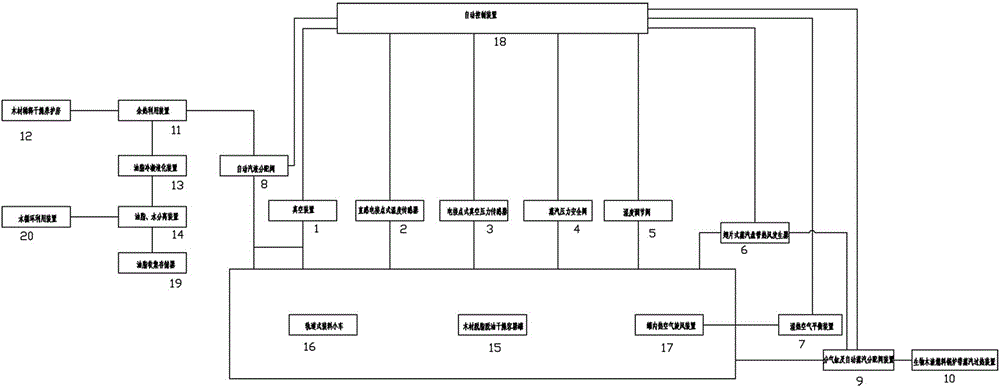

Image

Examples

Embodiment

[0048] Material selection: southern masson pine, thickness 20mm

[0049] The high temperature and high pressure steam degreasing and deoiling process steps of pine wood include:

[0050] 1) Loading: Put the semi-finished wood products and wood trims on the track-type loading trolley 16;

[0051] 2), material into the tank: push the track-type charging trolley 16 into the wood degreasing and deoiling drying container tank 15, and close the tank door;

[0052] 3) Start work: Turn on the automatic control device 18 to make the whole set of devices enter the working state, turn on the bio-wood residue fuel boiler with steam superheating device 10 to transport the superheated steam to the wood degreasing and deoiling drying container tank 15;

[0053] 4), heat up and discharge the air in the container: open the sub-cylinder and the automatic steam distribution valve device 9 to heat up and steam the wood, open the emptying valve on the top of the wood degreasing and deoiling dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com