Vehicle safety integrated monitoring system for running trains

A comprehensive monitoring and train technology, applied in the control system of the transportation center, railway signal and safety, signal indicators on vehicles, etc., can solve the problems of high operation and maintenance costs, inability to monitor temperature distribution, and lack of monitoring camera devices , to achieve the effect of improving processing speed and reliability, avoiding unreliable information transmission, and saving operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

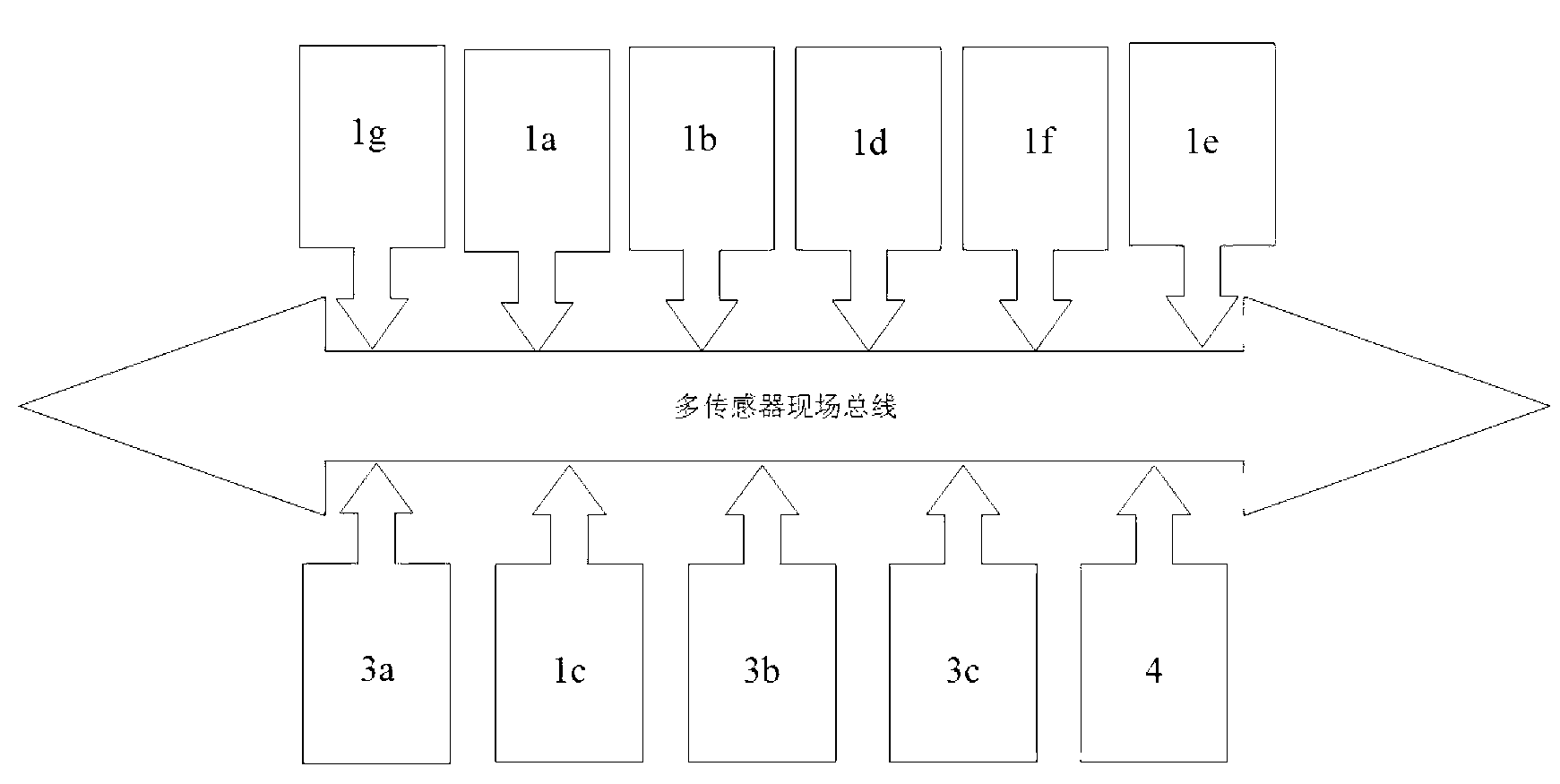

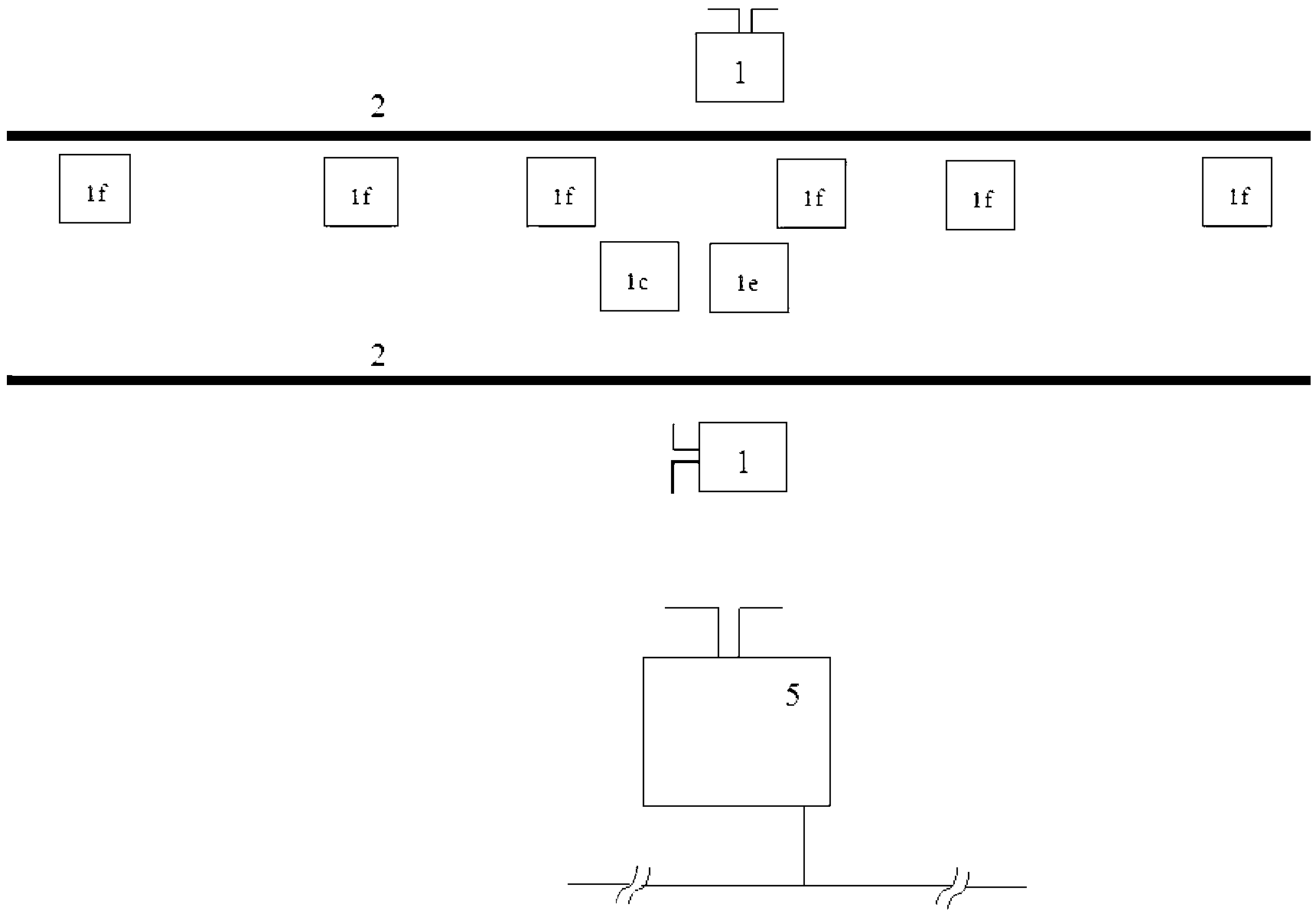

[0047] Such as figure 1 and figure 2 Shown, a kind of specific embodiment of the present invention is, a kind of integrated safety monitoring system of running train vehicle, comprises:

[0048] Railside multi-sensor field bus intelligent detection unit 1, located on the outside of rail 2, is used to detect the train vehicle data information under the normal operation state or sudden speed change, emergency stop, stop and restart operation state of the train passing through this area; The multi-sensor field bus of the trackside multi-sensor field bus intelligent detection unit 1 is matched with the sensor, and is used to collect, distribute and transmit the data information detected by the sensor;

[0049] The transfer computer unit 3 of the multi-element information processor is used for buffering, storing and transferring the data information transmitted by the multi-sensor field bus;

[0050] The trackside wireless communication unit 4 is used to wirelessly transmit the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com