Noise suppression sheet made from compound material

A technology of noise suppression sheet and composite material, applied in electrical components, magnetic field/electric field shielding, etc., can solve problems such as reducing resonance frequency, occupying circuit area, and reducing system reliability of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Further, the preparation method of the above-mentioned NiZn ferrite includes the following.

[0039] Step 1.1, the Fe 2 o 3 , NiO, CuO, ZnO by weight ratio to Fe 2 o 3 : 62~68wt%, NiO: 4~30wt%, CuO: 3~12wt%, ZnO: 1~22wt%, mixed and stirred into powder.

[0040] Step 1.2, add deionized water of equal mass to the powder obtained in step 1.1, put it into a ball mill jar and mill for 1 to 4 hours, wherein the ratio of the grinding medium to the powder is 4:1 to 5:1 (most Good is 5:1).

[0041] Step 1.3, drying the powder obtained in step 1.2 at a temperature of 100-190°C to remove moisture.

[0042] In step 1.4, put the powder obtained in step 1.3 into a sintering furnace for pre-sintering, wherein the pre-sintering temperature is 900-1000° C., and the pre-sintering time is 1.8-2.5 hours.

[0043] Step 1.5, put the powder obtained in step 1.4 back into the ball mill tank, add deionized water of equal mass, the ratio of grinding medium to powder is 4:1~5:1 (preferably ...

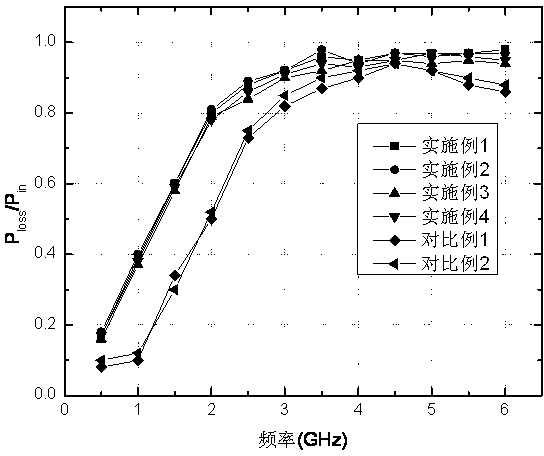

Embodiment 1

[0065] Example 1: The mixing ratio of NiZn ferrite and FeSiAl composite material is 1:4 and the tape casting method is used. The test sample size is 5*5*0.1cm.

Embodiment 2

[0066] Example 2: The mixing ratio of NiZn ferrite and FeSiAl composite material is 1:5, using tape casting method. The test sample size is 5*5*0.1cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com