Tobacco-coated controlled-release fertilizer as well as preparation method and application thereof

A technology of coated controlled-release fertilizer and controlled-release fertilizer, which is applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of restricting the quality of tobacco leaves and low potassium content, and achieve excellent nutrient resistance control function, smooth and consistent surface, Effect of increasing potassium content in tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

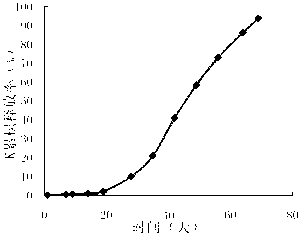

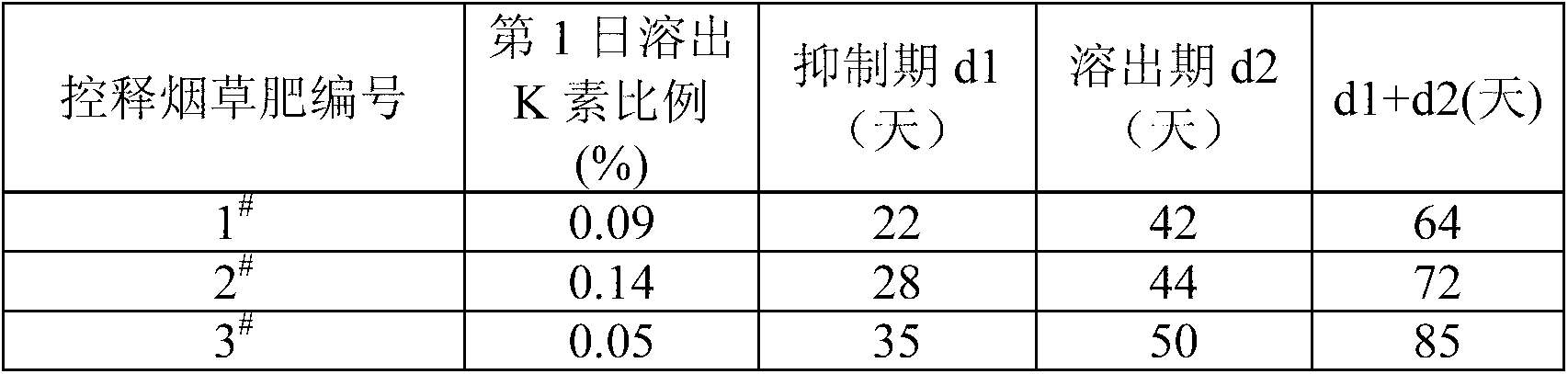

[0056] Embodiment 1, the preparation of tobacco-coated controlled-release fertilizer

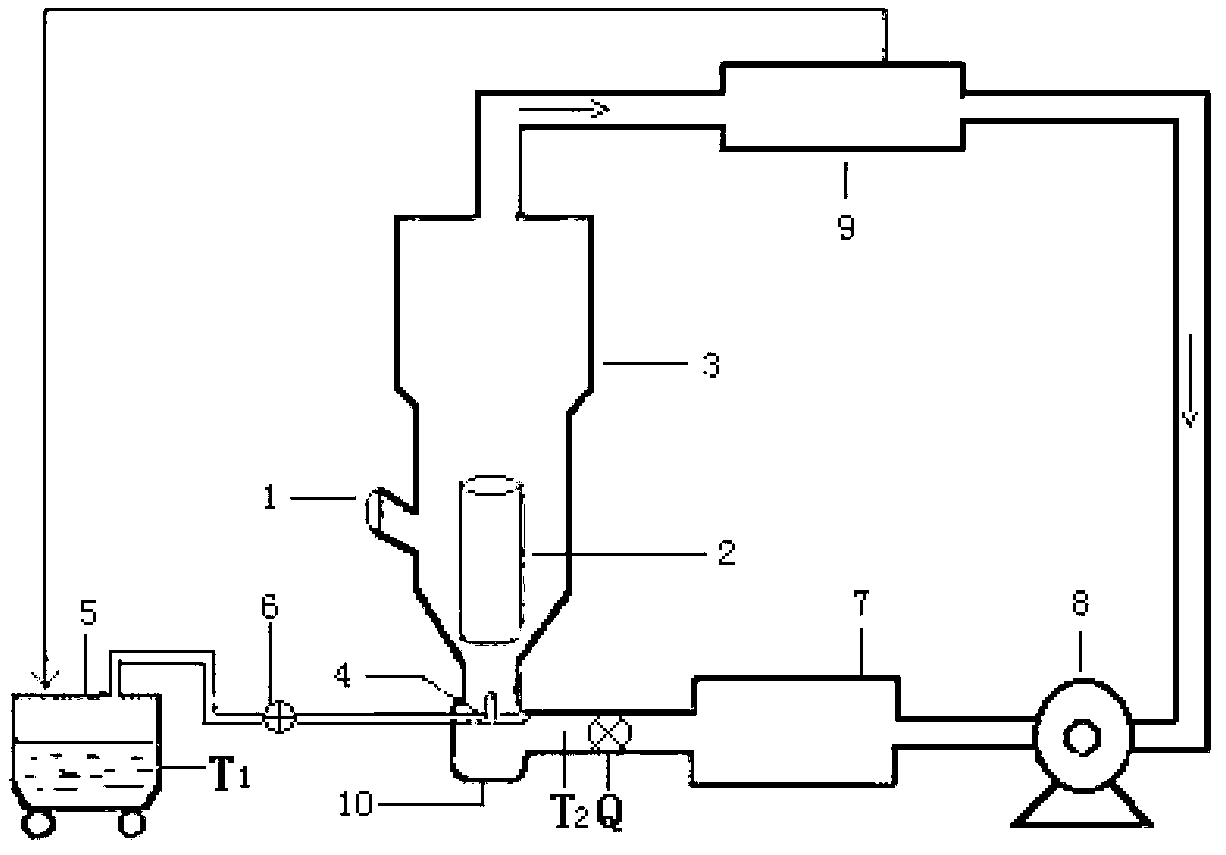

[0057] 1. Preparation of coating solution

[0058] Measure solvent tetrachlorethylene (density 1.6kg L -1 , boiling point 121°C) 40L was added to the dissolving tank ( figure 1 shown in 5). Accurately weigh 400.0g of recycled polypropylene particles (purchased from waste recycling companies in the market), 100.0g of EVA, 200g of linear low-density polyethylene, and 400g of cornstarch (200-300 mesh) and add them together for dissolution and stirring. Heat and stir for 2 hours, add 500g of talc powder (1500 mesh) after the polymer is completely dissolved, heat up to 115°C and heat and stir evenly to obtain a uniformly dispersed dispersion system, that is, to obtain a coating liquid, which is used for coating operations.

[0059] 2. Preparation of tobacco-coated controlled-release fertilizer

[0060] The spouted bed is used to coat the tobacco granular fertilizer for topdressing (NK compoun...

Embodiment 2

[0082] Embodiment 2, the preparation of tobacco-coated controlled-release fertilizer

[0083] 1. Preparation of coating solution

[0084] Measure solvent tetrachlorethylene (density 1.6kg L -1 , boiling point 121°C) 60L was added to the dissolving tank ( figure 1 shown in 5). Accurately weigh 540.0 g of reclaimed polypropylene granules (purchased from waste recycling companies in the market) with a particle size of 3-4 mm, EVA210.0 g, 240 g of linear low-density polyethylene, and 450 g of wheat starch (200-300 mesh) into the dissolving irrigation After stirring and raising the temperature to 110°C, heat and stir at a constant temperature for 2 hours, add 600g of calcium carbonate (800 mesh) after the polymer is completely dissolved, heat up to 115°C and keep stirring evenly to obtain a uniformly dispersed dispersion system, that is, to obtain a coating liquid, which is used for coating Membrane operation.

[0085] 2. Preparation of tobacco-coated controlled-release fertilize...

Embodiment 3

[0095] Embodiment 3, the preparation of tobacco coated controlled-release fertilizer

[0096] 1. Preparation of coating solution

[0097] Measure solvent tetrachlorethylene (density 1.6kg L -1 , boiling point 121°C) 80L was added to the dissolving tank ( figure 1 shown in 5). Accurately weigh 880.0 g of reclaimed polypropylene granules (purchased from market waste recycling companies) with a particle size of 3-4 mm, EVA240.0 g, 360 g of linear low-density polyethylene, and 480 g of potato starch (200-300 mesh) After stirring and raising the temperature to 110°C, heat and stir at a constant temperature for 2 hours. After the polymer is completely dissolved, add 1000g (1500 mesh) of talc powder, heat up to 115°C and keep stirring evenly to obtain a uniformly dispersed dispersion system, that is, to obtain a coating liquid, which is used for coating Membrane operation.

[0098] 2. Preparation of tobacco-coated controlled-release fertilizer

[0099] Weigh large particle tobac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com