Polyimide-based adhesive composition, cured product, adhesive sheet, laminate, and flexible printed circuit board

A technology of polyimide and polyimide resin, which is applied in the direction of adhesives, lamination, and lamination devices, which can solve the problems of strong adhesive layer viscosity and insufficient heat-resistant adhesiveness, and achieve heat-resistant adhesiveness Excellent, not easy to foam, excellent adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, although an Example and a comparative example are given and the present invention is concretely described, the scope of the present invention is not limited by them. In addition, in each example, parts and % are based on weight unless otherwise specified.

[0101]

manufacture example 1

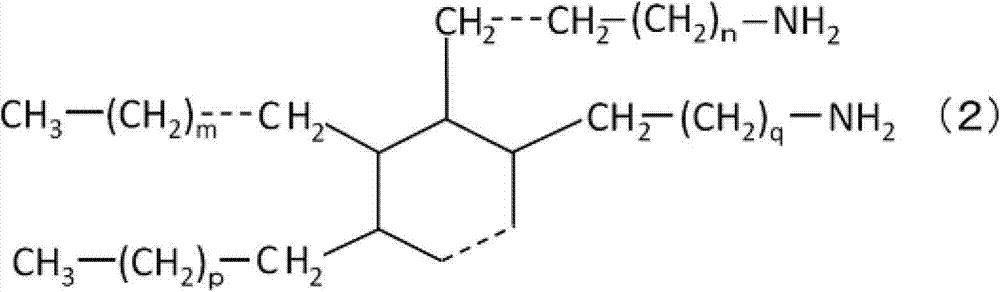

[0103] In a reaction vessel with a stirrer, a water separator, a thermometer and a nitrogen gas introduction tube, add 53.00 g of 3,3',4,4'-benzophenone tetracarboxylic dianhydride (trade name "BTDA", Daicel Chemical Industry Co., Ltd. Co., Ltd. hereinafter referred to simply as benzophenone tetracarboxylic dianhydride), 185.50 g of cyclohexanone, and 37.10 g of methylcyclohexane, and the solution was heated to 60°C. Next, after dropping 85.40 g of dimer diamine (trade name "PRIAMINE 1075", manufactured by Croda Japan Corporation. Hereinafter, simply referred to as dimer diamine), the imide was carried out at 140° C. for 1 hour. reaction to obtain a polyimide resin (A-1-1) solution (38.0% of non-volatile content). In addition, the molar ratio of the acid component / amine component was 1.04.

manufacture example 2

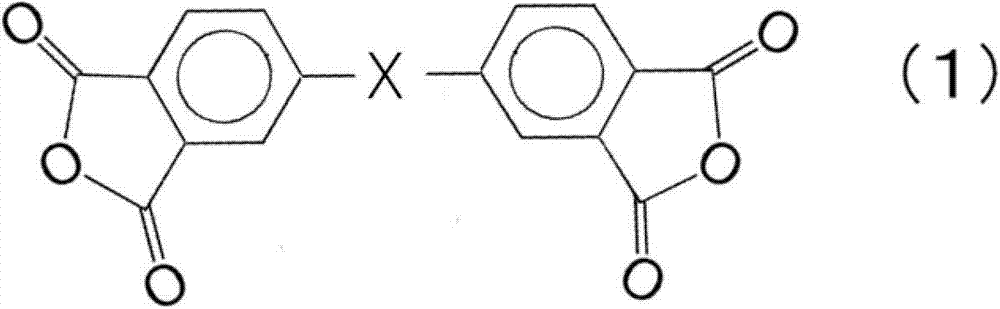

[0105] In the same reaction vessel as in Production Example 1, 53.00 g of 3,3',4,4'-diphenylsulfone tetracarboxylic dianhydride (manufactured by Shin Nippon Chemical Co., Ltd., trade name "リカシツド DSDA") was added. Hereinafter, referred to simply as diphenylsulfonetetracarboxylic dianhydride), 185.50 g of cyclohexanone, 37.10 g of methylcyclohexane, and the solution was heated to 60°C. Next, after gradually adding 76.82 g of dimer diamines, imidization reaction was performed at 140 degreeC for 1 hour, and the polyimide resin (A-1-2) solution whose nonvolatile matter was 36.0% was obtained. In addition, the molar ratio of the acid component / amine component was 1.04.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com