Yellow rice wine production technology by mixing wine with dregs after fermentation in front fermenting cylinder and front fermenting pot

A production process, rice wine technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of rice wine quality and bulkiness, and achieve the effects of short fermentation cycle, complete saccharification and fermentation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: dry original rice wine

[0039] The raw material formula of the former fermenter cylinder is:

[0040] Rice 125kg

[0041] Yellow rice wine koji 0.2kg

[0042] Raw wheat koji 10kg

[0043] Cooked wheat koji 2.5 kg

[0044] water 145kg

[0045] Each shift needs to feed 80 cylinders;

[0046] The raw material formula of one can of pre-fermentation tank is:

[0047] Rice 10000kg

[0048] Raw wheat koji 600 kg

[0049] Purebred Fortified Raw Wheat Koji 200 kg

[0050] Alpha-amylase 2.5 kg

[0051] Glucoamylase 2kg

[0052] Acid protease 1kg

[0053] Lactic acid 5 kg

[0054] Rice wine active dry yeast 11 kg

[0055] Water 10000~12000 kg

[0056] Each shift needs to feed 1 can;

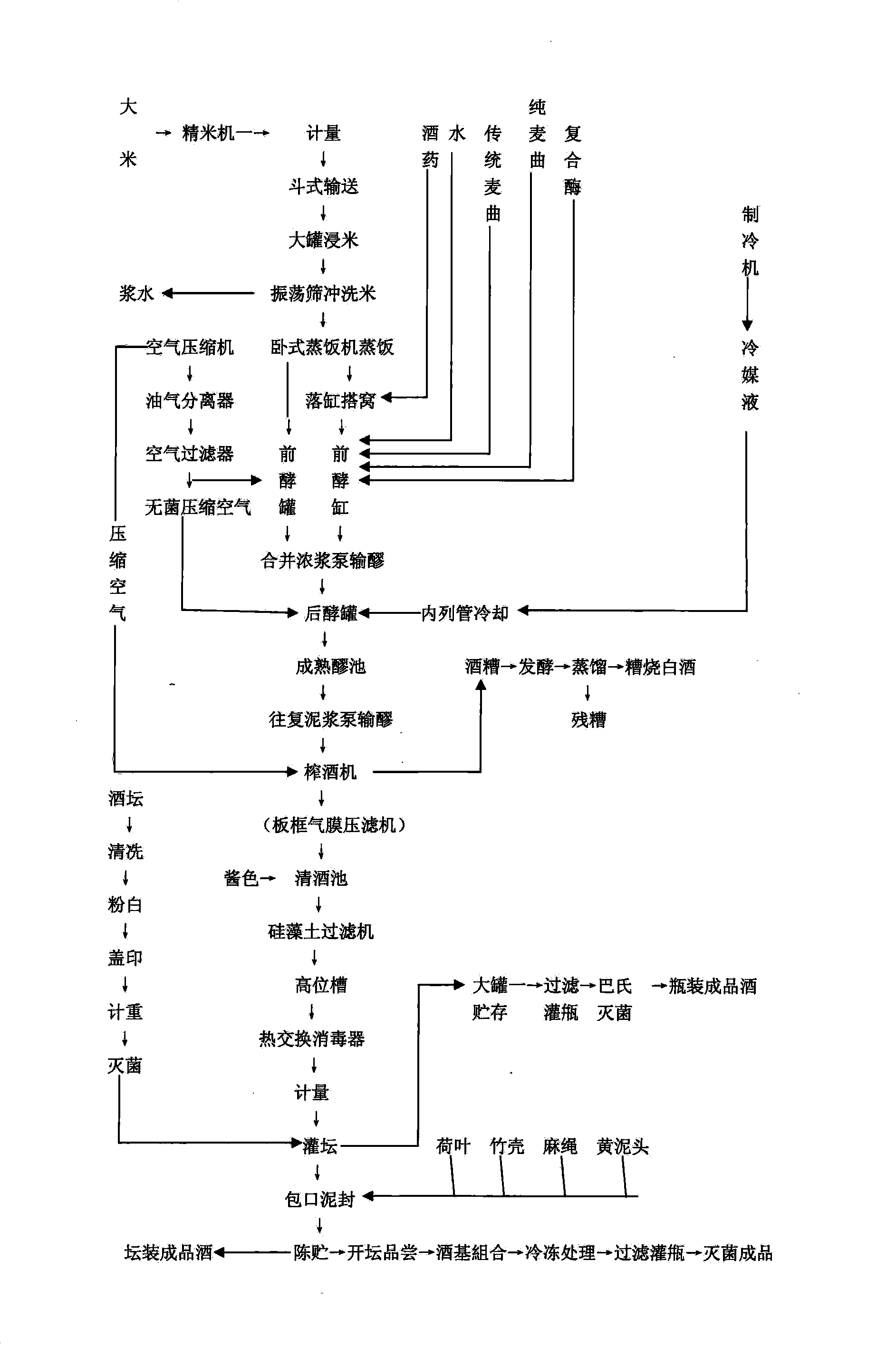

[0057] refer to figure 1 , the concrete steps of the production process of the rice wine of the present embodiment are:

[0058] (1) Preparation of rice:

[0059] The rice is refined according to the whiteness requirement, and the ash and rice bran screened out after ...

Embodiment 2

[0089] Embodiment 2: semi-dry type original rice wine

[0090] The raw material formula of the former fermenter cylinder is:

[0091] Rice 130kg

[0092] Yellow rice wine koji 0.25kg

[0093] Raw wheat koji 12kg

[0094] Cooked wheat koji 3.6 kg

[0095] water 145kg

[0096] Each shift needs to feed 80 cylinders;

[0097] The raw material formula of one can of pre-fermentation tank is:

[0098] Rice 10400 kg

[0099] Raw wheat koji 832 kg

[0100] Purebred Fortified Raw Wheat Koji 208kg

[0101] Alpha-amylase 2 kg

[0102] Glucoamylase 2kg

[0103] Acid protease 1.04kg

[0104] Lactic acid 6kg

[0105] Rice wine active dry yeast 11.5 kg

[0106] Water 10000~12000 kg

[0107] Each shift needs to feed 1 can;

[0108] The production process of this embodiment is the same as that of Embodiment 1.

[0109] The various indexes of the rice wine finished product of the present embodiment are:

[0110] Sensory requirements: orange yellow, clear and transparent. It has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com