High-energy-absorptivity aluminum alloy for automobile bodies

An automobile body and energy-absorbing technology, applied in the field of aluminum magnesium silicon aluminum alloy, can solve problems such as poor compressive cracking resistance, and achieve the effects of improving compressive cracking resistance, improving the structure of the alloy, and improving the strength of the alloy.

Active Publication Date: 2013-09-11

HUNAN UNIV

View PDF9 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

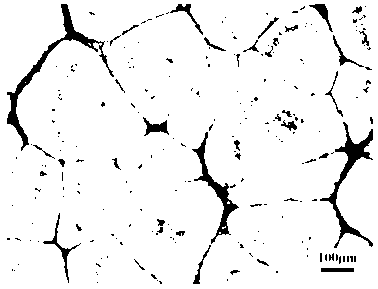

[0003] The technical problem to be solved by the present invention is, aiming at the defects of existing conventional commercial Al-Mg-Si alloys with poor resistance to crushing and cracking, propose a kind of alloy with reasonable component distribution ratio, easy processing and manufacturing, simple operation technology, and the use of Ti and Zr elements High energy-absorbing aluminum alloy and its preparation method for improving the microstructure of aluminum alloy and improving its comprehensive mechanical properties by alloying

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0028] Embodiment: The weight percent composition is: 0.6%Mg, 0.43%Si, 0.18%Cu, 0.21%Fe, 0.03%Mn, 0.03Cr%, 0.03%Zn, 0.3%Ti, 0.3%Zr, and the balance is Al;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a high-energy-absorptivity aluminum alloy for automobile bodies, which comprises the following components in percentage by weight: 0.56%-0.64% of Mg, 0.42%-0.50% of Si, 0.17%-0.19% of Cu, 0.20%-0.22% of Fe, 0.028%-0.032% of Mn, 0.028%-0.032% of Cr, 0.028%-0.032% of Zn, 0.29%-0.31% of Ti, 0.29%-0.31% of Zr and the balance of Al. The preparation method comprises the following steps: preparing components according to weight percents, melting by heating to 740-750 DEG C, cooling, standing,, refining, and casting into a 250-300 DEG C iron mold; and carrying out homogenizing treatment on the cast ingot at 560 DEG C for 9 hours, quickly cooling with water, heating, extruding, carrying out water or fog quenching, and carrying out artificial aging at 180 DEG C. The invention has the advantages of reasonable component proportion, simple operating technique and favorable hot extrusion formability.

Description

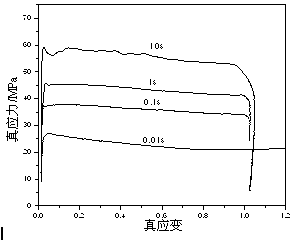

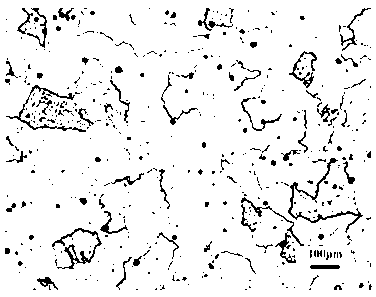

technical field [0001] The invention relates to an aluminum-magnesium-silicon-aluminum alloy, in particular to a new Al-Mg-Si aluminum alloy containing elements Ti and Zr, which is suitable for structural materials of typical key safety components such as automobile anti-collision beams and energy-absorbing boxes. Background technique [0002] Lightweight is considered to be the most effective way to achieve sustainable development of the transportation industry. Al-Mg-Si alloy has high specific strength, high specific stiffness, good welding performance, good recyclability, and is an ideal material for automobile lightweight. Among the existing conventional commercial Al-Mg-Si alloys, the 6061 aluminum alloy has higher strength and good hot extrusion formability, and has application prospects as an aluminum alloy for vehicle body. However, its ductility is poor, the deformation and wrinkles are irregular during high-speed impact, the crack resistance is poor, and the energ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C21/08C22F1/047C22F1/05

Inventor 李落星刘志文王冠

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com