Hydrogen-producing microbial electrolytic cell and biological cathode domestication method

A technology of microbial electrolysis cell and biocathode, applied in the field of hydrogen-producing microbial electrolysis cell and its biocathode domestication, can solve the problems of high cost, catalyst poisoning and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Cultivation of anode electrogenic microbial populations in microbial fuel cell mode

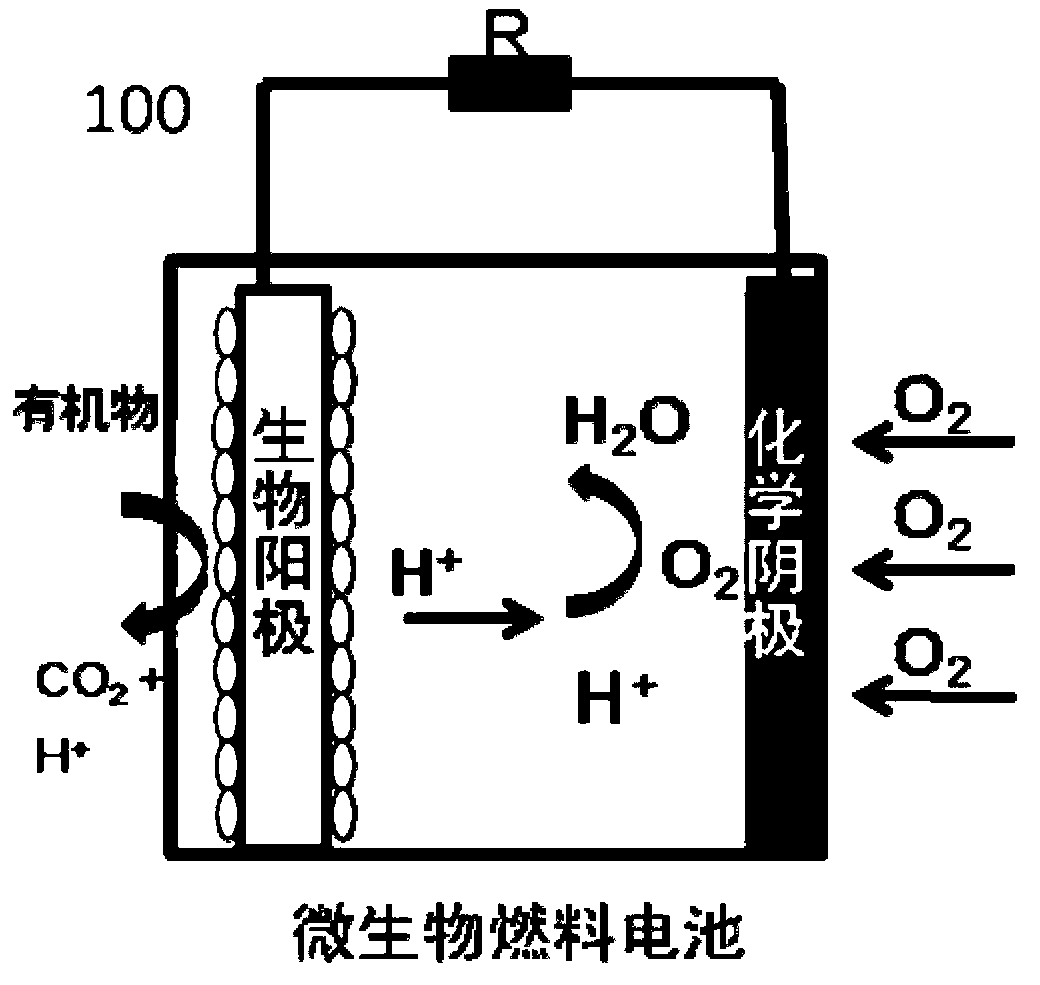

[0030] The structure of the adopted microbial fuel cell (100) is as follows figure 1 shown in the schematic diagram. Specific steps:

[0031] Add the first solution (see below for ingredients) to the microbial fuel cell (100), the anode of the microbial fuel cell (100) uses carbon felt as the base material, and the cathode uses acetylene black carbon film and brushes 0.5mg-Pt / cm 2 The catalyst is connected to the external resistance R=1000Ω in the closed circuit system, batch operation, and the voltage at both ends of the external resistance R is continuously monitored;

[0032] When the output voltage (the voltage across the external resistance R) of the microbial fuel cell (100) drops continuously and falls below 100mV in each operating cycle, replace the solution in the microbial fuel cell (100) with a fresh first solution, The replacement of the solution is repeated f...

Embodiment 2

[0035] Example 2: Domestication of anodic hydrogen phagocytic microbial populations under the hydrogen production mode of microbial electrolysis cells

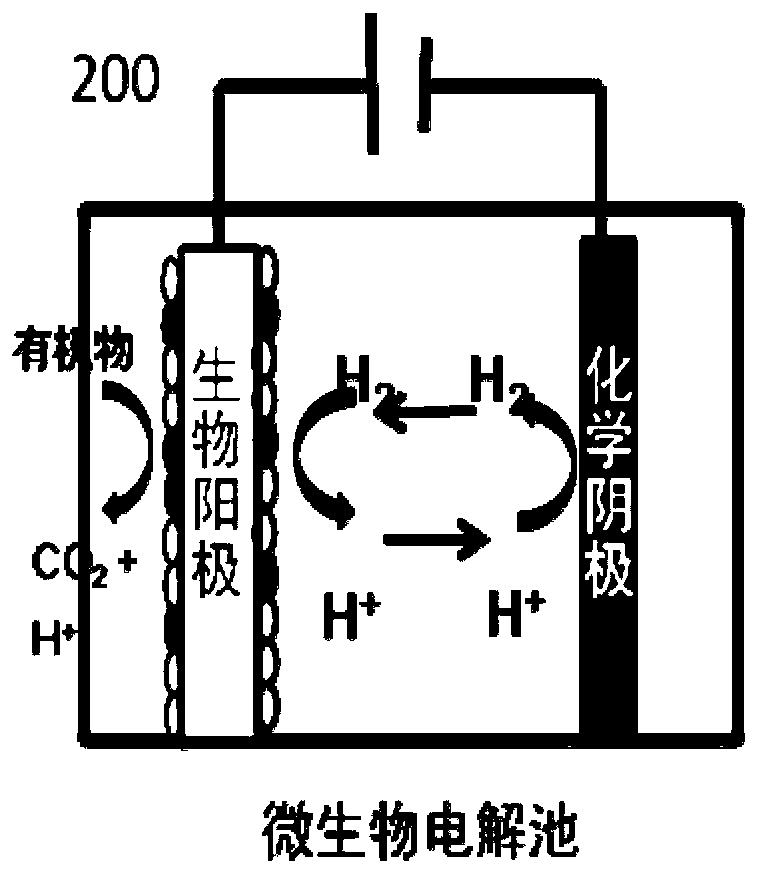

[0036] The structure of the electrolytic cell used is shown as figure 2 Shown as indicated. Specific steps:

[0037] B1) Transfer the bioanode started in step A to the microbial electrolysis cell (200) ( figure 2 ), as the bioanode of the electrolysis cell (200). The cathode of the microbial electrolytic cell (200) uses carbon cloth as the basic material, and the load is 0.5mg-Pt / cm 2 catalyst. After the first solution is added, a voltage of 0.6V is applied between the biological anode and the chemical cathode of the microbial electrolytic cell (200), and the batch operation is performed at room temperature, and the current intensity of the electrolytic cell (200) is continuously monitored. When in each batch cycle, the current density of the microbial electrolytic cell (200) drops from a stable plateau to 100-200A / m 3...

Embodiment 3

[0041] Example 3: Acclimatization and cultivation of cathode hydrogen-producing microorganisms in the three-electrode mode

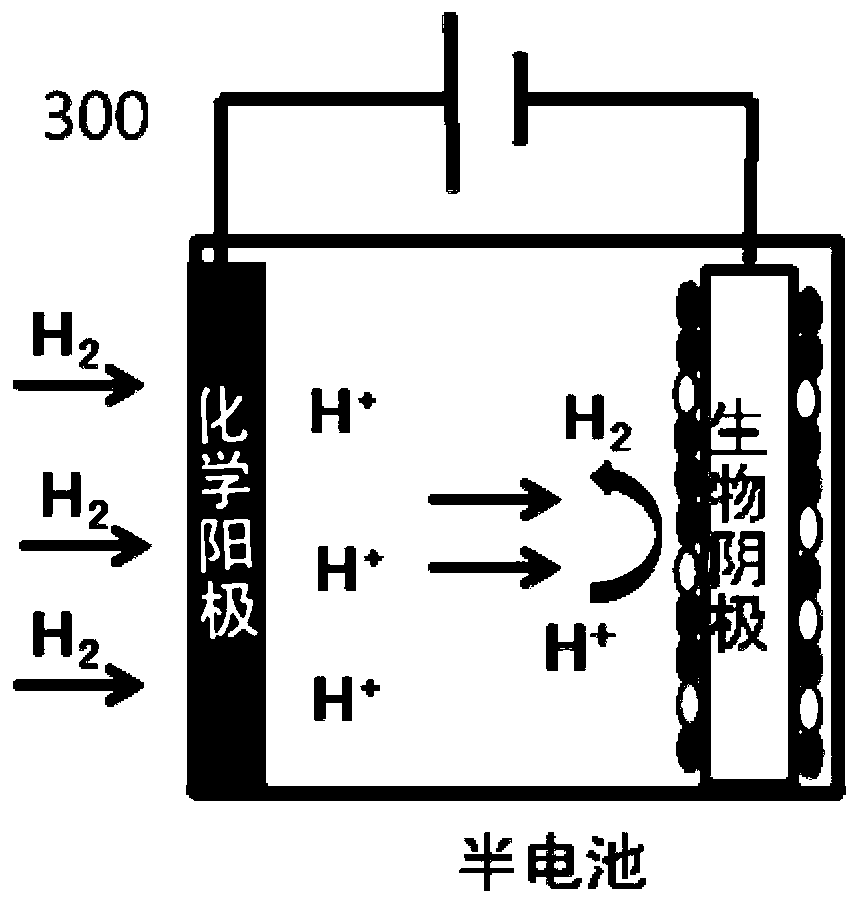

[0042] The structure of the three-electrode mode half-cell adopted is as follows image 3 Shown as indicated. Specific steps:

[0043] C1) The bioanode in step B) is used as the cathode, and the acetylene black carbon film is used as the chemical anode to form a half-cell (300).

[0044] C2) Add the second solution (composition below) to the half-cell, keep the potential of the working electrode constant at -1.1V (relative to the saturated calomel electrode), pass hydrogen gas into one side of the chemical anode, and operate at room temperature. When the half-cell (300) current density drops below 80A / m in each cycle 3 , the solution in the half-cell (300) is replaced with a new second solution, and the solution replacement is repeated for several cycles until the half-cell (300) obtains a stable current. Such as Figure 6 As shown, when the biocath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com