Piston rolling friction or suspension friction method and anti-abrasion piston device implementing method

A rolling friction and anti-wear technology, which is applied to fluid pressure actuators, components of pumping devices for elastic fluids, pistons, etc., can solve problems such as ineffective effects, increased energy consumption, and production stop losses, and achieve reduction Strength and toughness requirements, reducing energy consumption, and reducing the effect of material volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

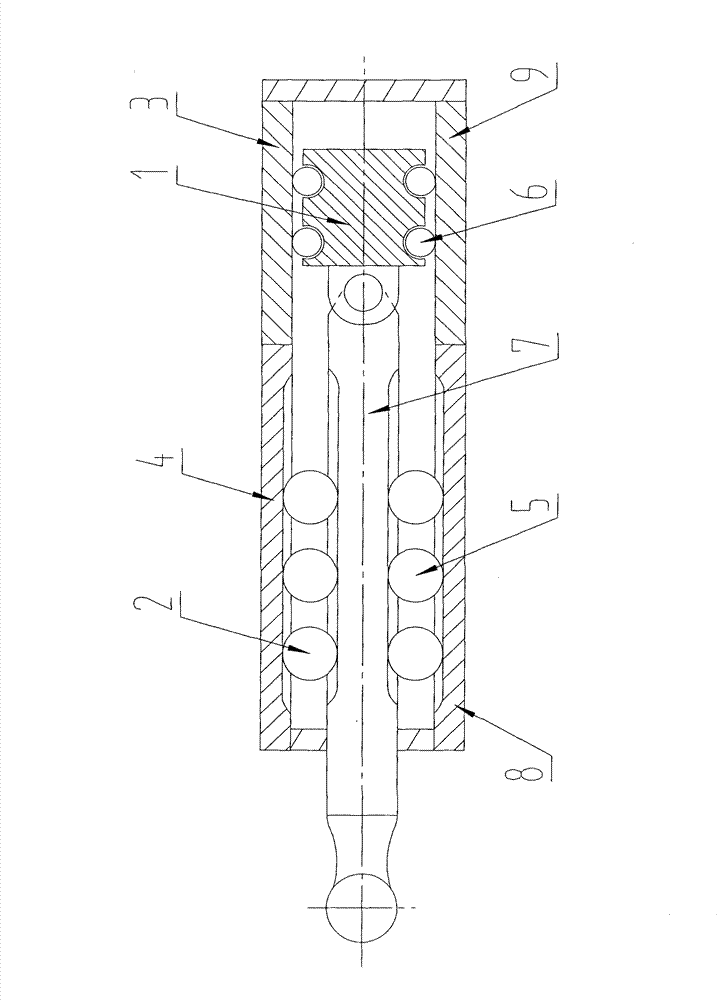

[0145] figure 1It is the anti-wear piston device described in Example 1, which includes a piston 1, a friction body 2, a cylinder body 3, and a friction body support 4. The friction body 2 is a rolling body, and the rolling body includes a guide rolling body 5 and a piston rolling body. The body 6, the guide rolling body 5 and the piston rolling body 6 are separated, the piston 1 and the friction body 2 are arranged in the cylinder body 3, the friction body 2 supports the relative reciprocating motion of the piston 1 and the cylinder body 3 by rolling friction, and the piston 1 includes a piston rod 7 , the piston rod is connected separately with the piston 1, the friction body support 4 is a rolling body support, the rolling body support includes a guide rolling body support 8 and a piston rolling body support 9, the guide rolling body support 8 and the cylinder body 3 Split connection, the piston rolling element support 9 is integrated with the cylinder body.

[0146] The p...

Embodiment 2

[0151] figure 2 It is the anti-wear piston device described in Embodiment 2, which includes a piston 1, a friction body 2, a cylinder body 3, and a friction body support 4. The friction body 2 is a suspension, and the suspension includes a guide suspension 10 and a piston suspension. Body 11, guiding suspension 10 and piston suspension 11 are separated, piston 1 includes piston rod 7, piston rod and piston 1 are integrated, friction body support 4 is a suspension support, and suspension support includes guide suspension The support 12 and the piston suspension support 13, the guide suspension support 12 and the piston suspension support 13 are integrated, the suspension support and the cylinder body 3 are integrated, the suspension support is a magnetic suspension support, and the magnetic suspension The support is a permanent magnetic levitation support, an N-pole permanent magnetic levitation body is set on the piston rod 7, an N-pole permanent magnetic levitation body is s...

Embodiment 3

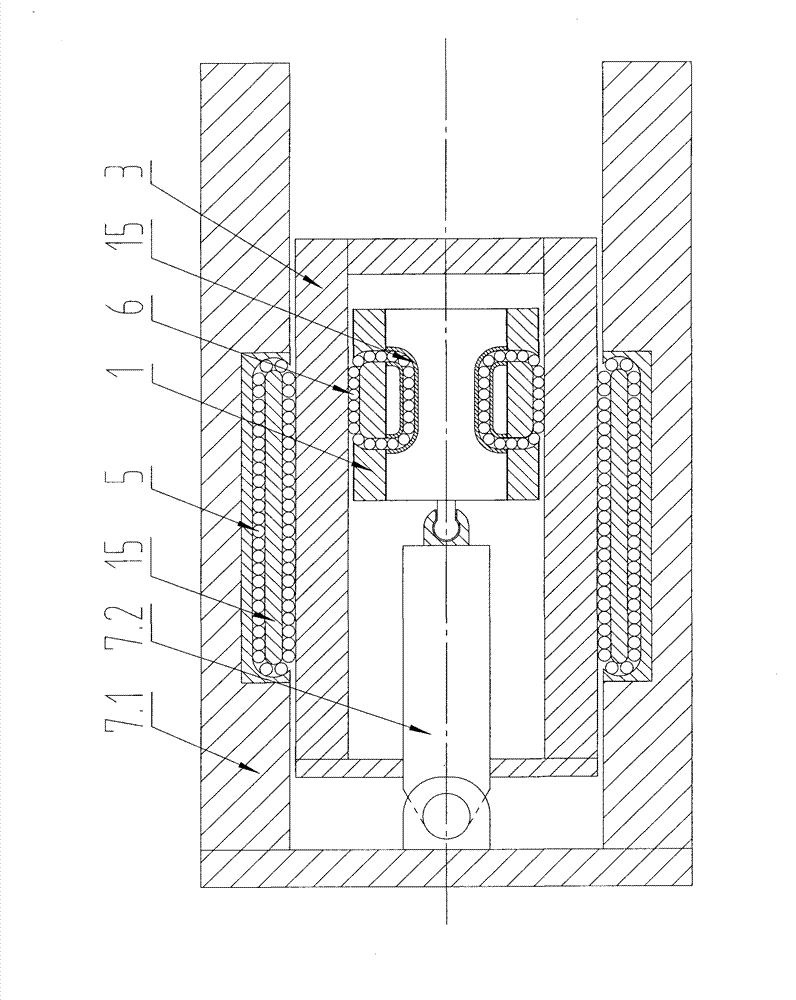

[0158] image 3 , Figure 4 It is the anti-wear piston device described in Embodiment 3, which includes a piston 1, a friction body 2, and a cylinder body 3. The piston 1 is provided with more than two rows of friction bodies 2, and more than two rows of friction bodies 2 bear Gravity load, a row of friction bodies 2 has at least one friction body 2 supporting the reciprocating impact of the piston 1, avoiding the concentrated damage to the friction body caused by only one row of friction bodies 2 bearing the gravity load of the piston 1, the friction body 2 supports the piston 1 and the cylinder body 3 Rolling friction or suspension friction relatively reciprocates, and the friction body 2 and the piston 1 are arranged separately.

[0159] The friction body 2 can be connected with the piston 1 or integrated.

[0160] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com