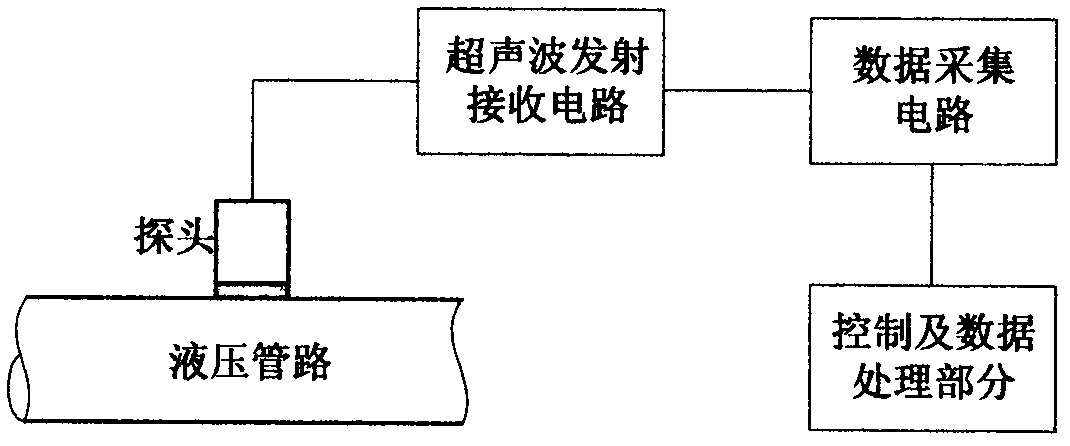

Small integration ultrasonic device for measuring pressure outside pipe with small pipe diameter

A pressure measuring device and ultrasonic technology, applied in the direction of fluid pressure measurement using acoustic methods, can solve the problems of small size, large safety factor, low power consumption, etc., and achieve the effect of small size, low power consumption, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

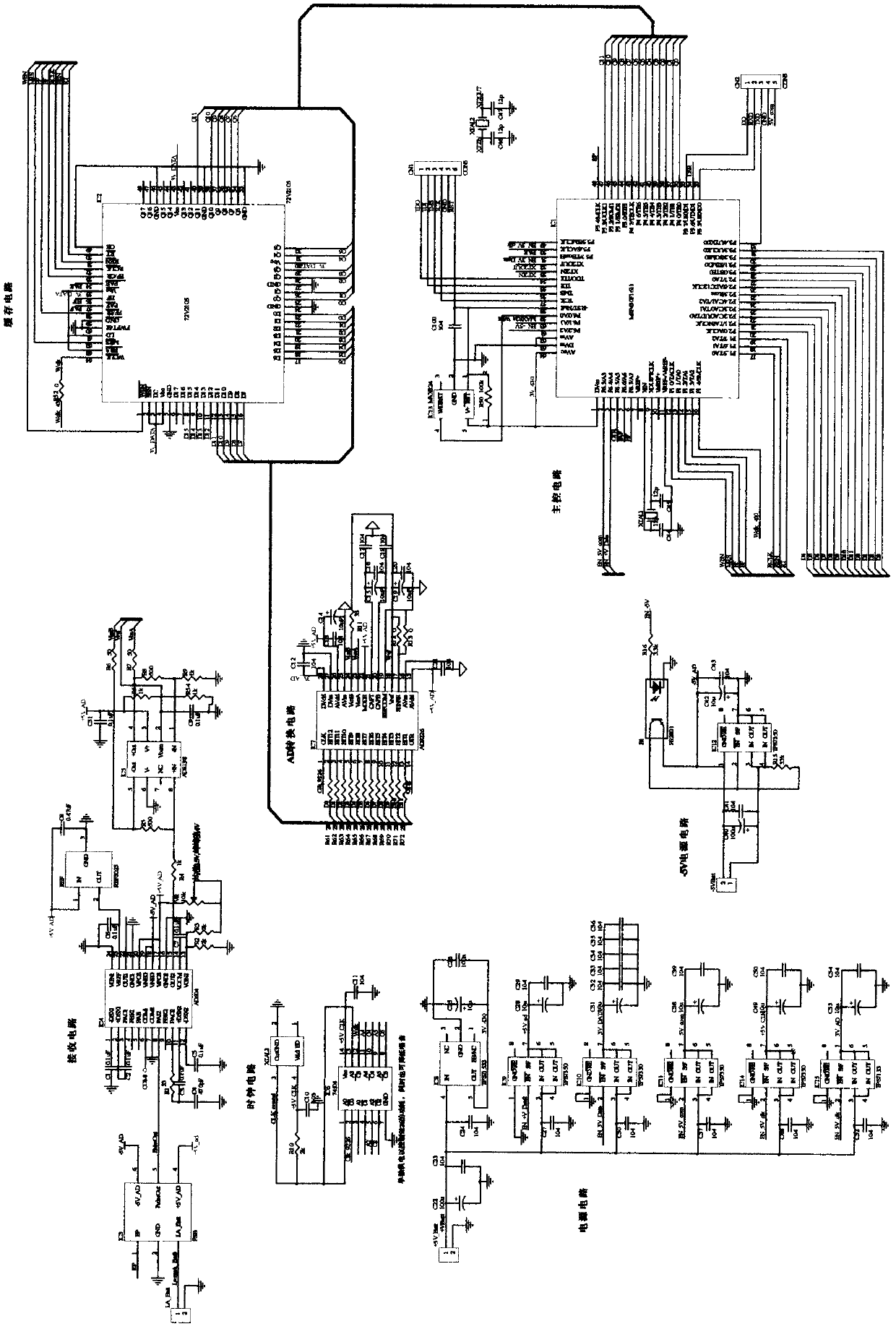

[0038] In order to test the feasibility of the ultrasonic tube external pressure measuring device, based on the GYZT-2 hydraulic test bench in the laboratory, a pipeline with an outer diameter of 28mm, a wall thickness of 3mm, and an inner diameter of 22mm was measured. , the echo signal detected by the ultrasonic probe changes, and the ultrasonic tube external pressure measuring device will collect the ultrasonic primary echo signal in real time, and use the embedded algorithm to calculate the pressure. The test is set to pressurize with 2MPa as the step length, after boosting to 20MPa, and then step down to 0MPa. During the test, 30 sets of data were collected at all levels of pressure.

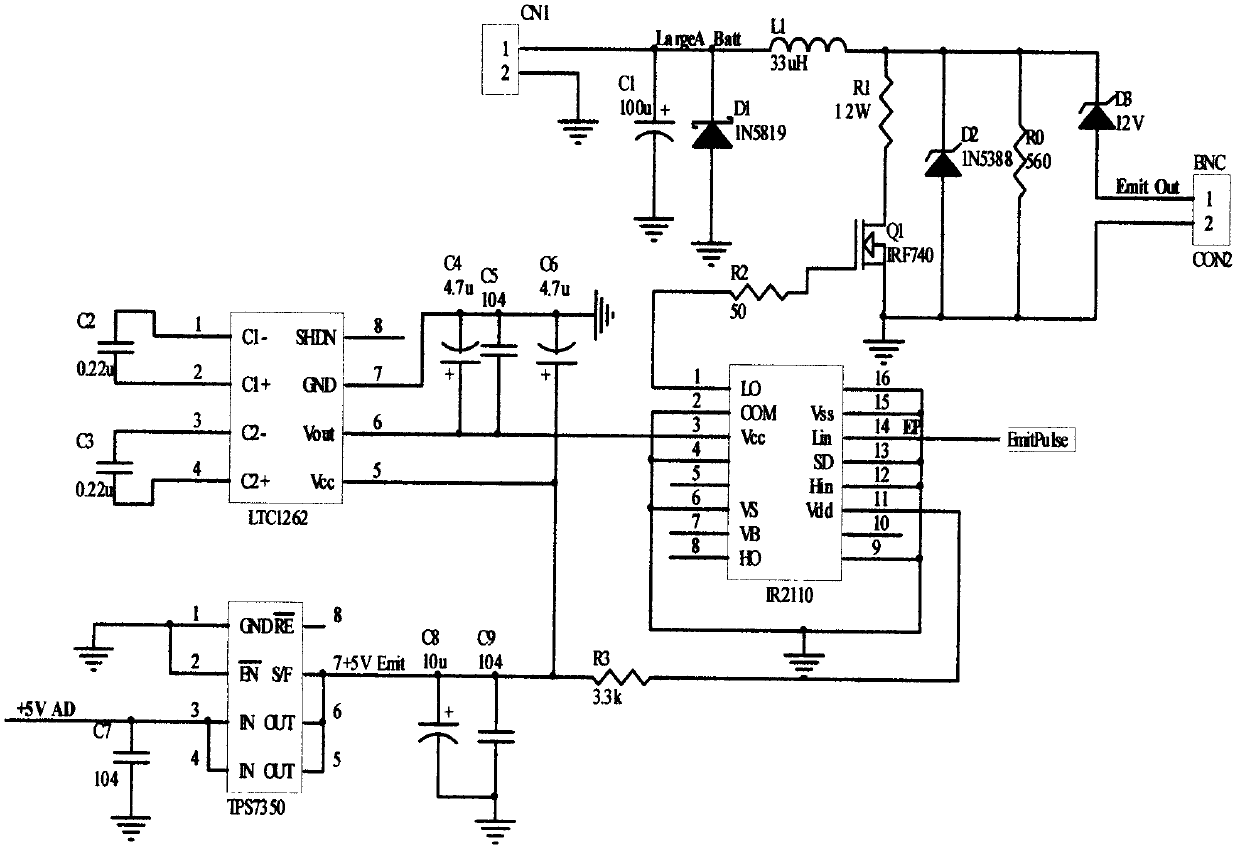

[0039] see figure 2 : The novel transmitting circuit designed for the present invention adopts the low-drain-source resistance R1 and the field effect transistor IRF740 with a very high-speed voltage change gradient as a fast electronic switch, and connects the low-voltage input path and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com