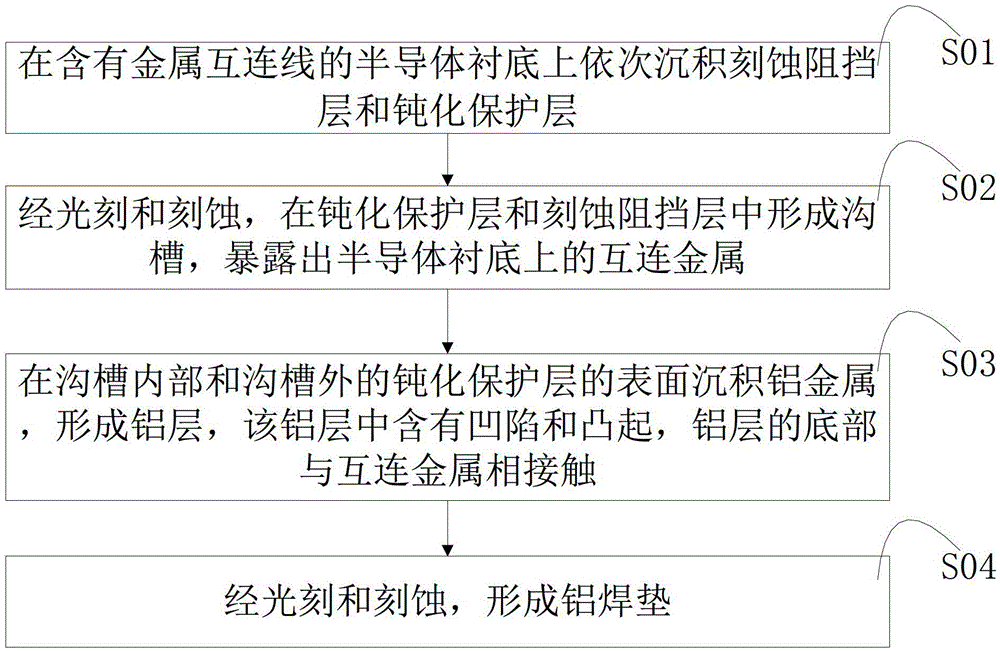

A kind of manufacturing method of aluminum welding pad

A manufacturing method and technology of aluminum welding pads, applied in the field of manufacturing aluminum welding pads, can solve problems such as large process influence, easy generation of whiskers, restrictions, etc., to improve quality and reliability, avoid residues, and eliminate protrusions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention can have various changes in different examples without departing from the scope of the invention, and that the descriptions and illustrations therein are illustrative in nature rather than limiting the invention.

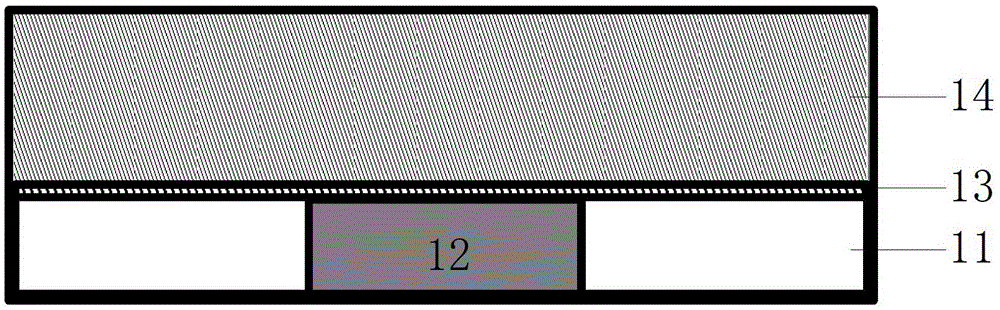

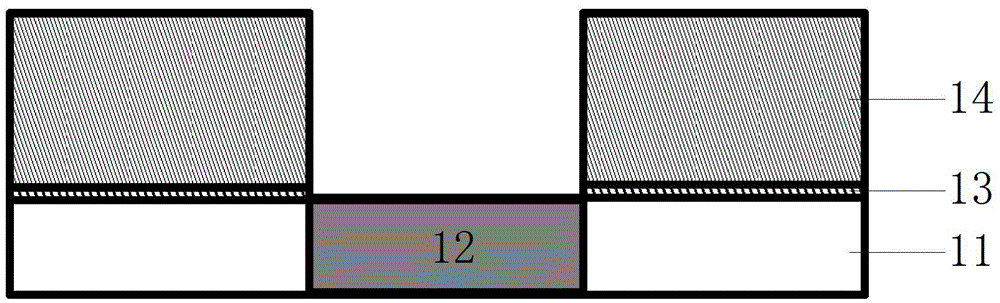

[0037] The following is attached Figure 6-12 , the manufacturing method of the aluminum pad of the present invention is further described in detail through specific embodiments, wherein, Figure 7-12 It is a schematic diagram of the cross-sectional structure corresponding to each preparation step of the manufacturing method of the aluminum pad in a preferred embodiment of the present invention

[0038] It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com