Water pressure transfer method, transfer film for water pressure transfer, ink for transfer film, and water pressure transfer product

A technology of hydraulic transfer printing and water-soluble film, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of difficult gloss adjustment and narrowing of gloss adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-25 and comparative example 1-5

[0114] Examples 1-25 and Comparative Examples 1-5 of the first embodiment used the following inks, activators, transfer films, and additives.

[0115] 1. Composition of ink

[0116] Using four-color inks of yellow, red, blue, and black, an organic solvent is added in order to make the base composition of each ink contain a coloring pigment, a resin component, and a dispersant, and to enable the ink to be coated. A commercially available varnish was used for a resin component and a part of the solvent. The coloring pigments of the four-color inks are as follows.

[0117] Yellow ink: metal oxide (inorganic)

[0118] Product nameSICOPALYELLOWL1600

[0119] (manufactured by BASFCORATION)

[0120] Red ink: naphthol dye (organic)

[0121] Product name NOVOPERMREDF5RK

[0122] (manufactured by CLARIANT Japan K.K.)

[0123] Blue ink: copper phthalocyanine (organic)

[0124] Product namePVFASTBLUEA2R

[0125] (manufactured by CLARIANT Japan K.K.)

[0126] Black ink: Carbon-ba...

Embodiment 26-61

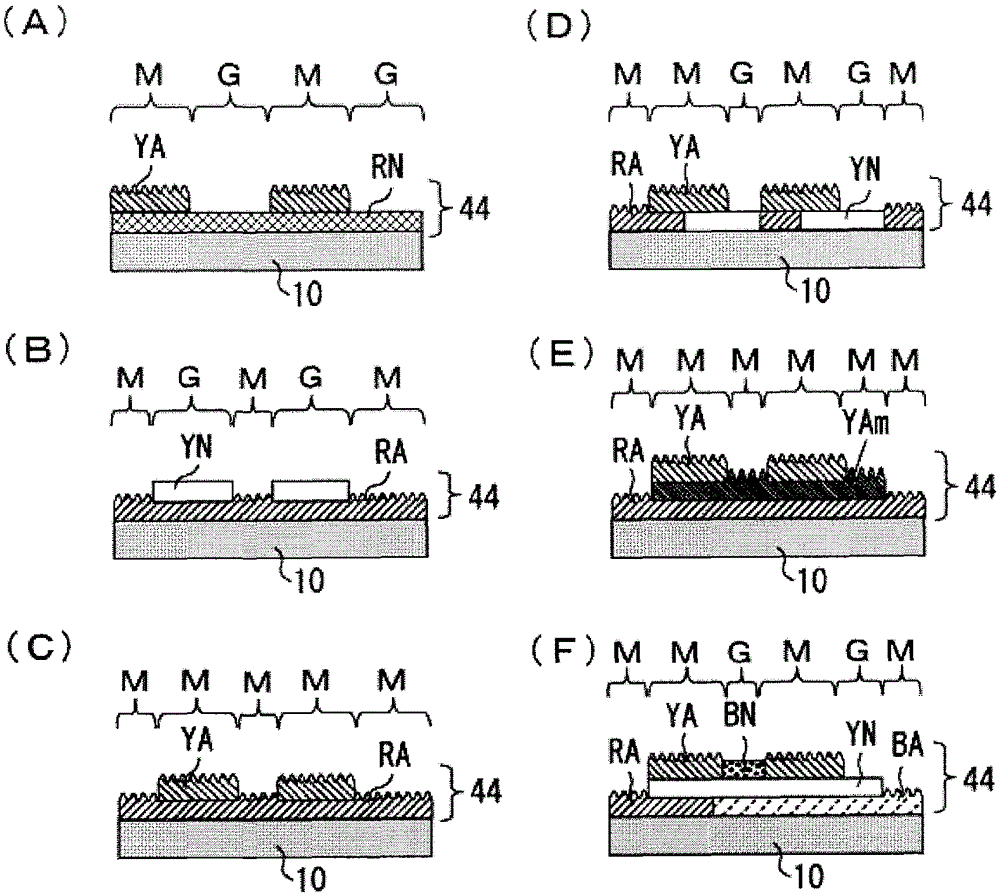

[0165]As shown in the following Tables 2A and 2B, Examples 26 to 61 of the second aspect show two types in which the compounding amount of the ultraviolet transmittance reducing agent is different by changing the ink color and the compounding amount in various ways. The result of evaluating the high and low gloss pattern part and its gloss difference (total difference (Gross difference)) when the layers of ink I and II are arranged adjacent to each other. In the ink I and II of the embodiment 26-61 of the second mode, the preceding numerals represent the numbering of the embodiment 1 of the table 1, and the English letters at the back represent the English initials of the colors of the table 1, for example, "1- Y" indicates that the same yellow ink as that of Example 1 was used, "3-B" indicates that the same blue ink as that of Example 3 was used, and "8-R" indicates that the same blue ink as that of Example 3 was used. The red ink of 8 is the same as the red ink, and the foll...

Embodiment 62-89

[0175] (for the embodiment 62-89 and the embodiment 90-107 of the third mode)

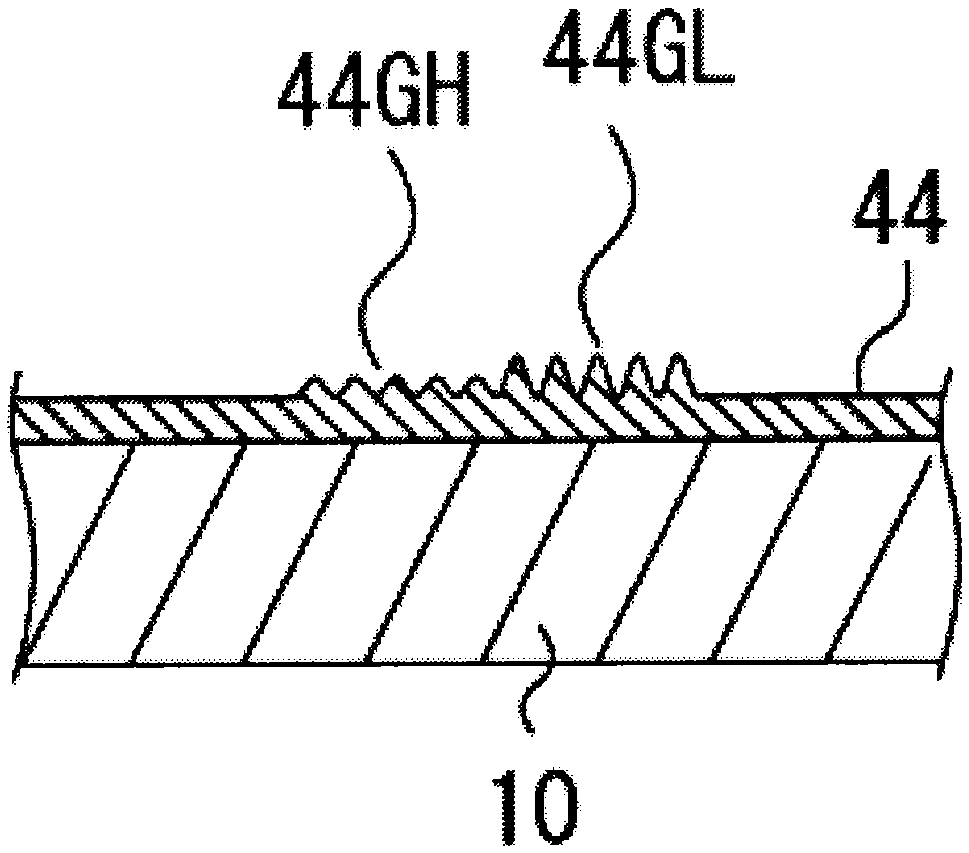

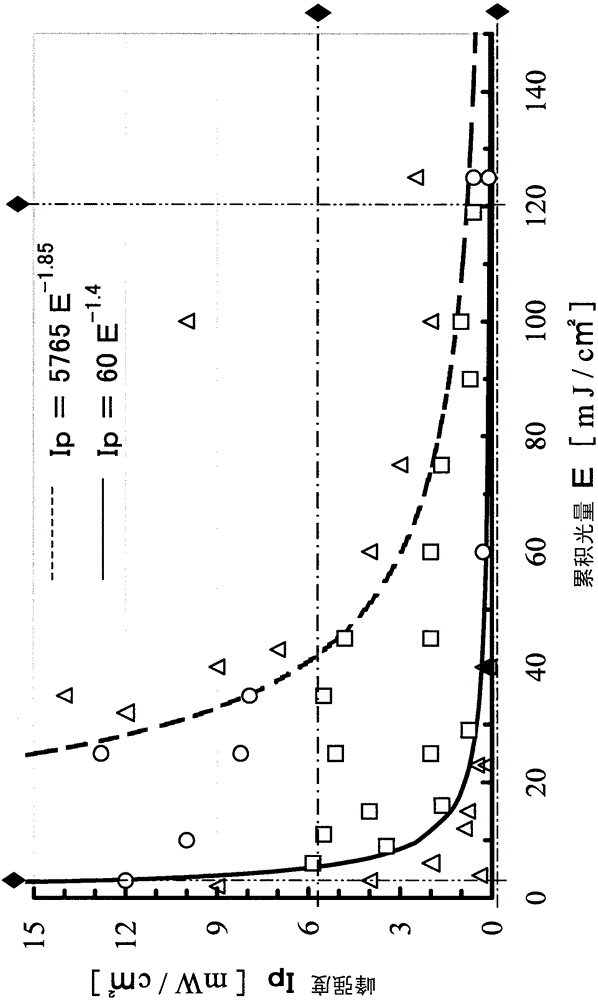

[0176] In the embodiments based on the first mode and the second mode, the peak intensity and cumulative light quantity of the ultraviolet rays for pre-irradiation, the peak intensity and the cumulative light quantity of the ultraviolet rays for main irradiation are kept constant, and in the embodiments of the third mode 62-89 and In Examples 90-107, as shown in the following Tables 3A and 3B and Tables 4A and 4B, various changes were made to the peak intensity and cumulative light intensity of ultraviolet rays for pre-irradiation and main irradiation to evaluate the use of Example 3. , 9 and 14 are the results of the matting effect (reduction of gloss) of the ink layer of the ink.

[0177] [Table 3A]

[0178]

[0179] For the matting effects of Tables 3B and 4B, "◎" of the plate means that the average value of the total value of the yellow, blue, and red ink layers (hereinafter referred to as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com