Ceramic-ceramic composites and process therefor, nuclear fuels formed thereby, and nuclear reactor systems and processes operated therewith

A technology of ceramic composite materials and ceramic materials, applied in the field of nuclear power generation materials, can solve problems such as low thermal conductivity and large temperature gradient, achieve high thermal conductivity, increase thermal conductivity, and improve the effect of fission gas retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

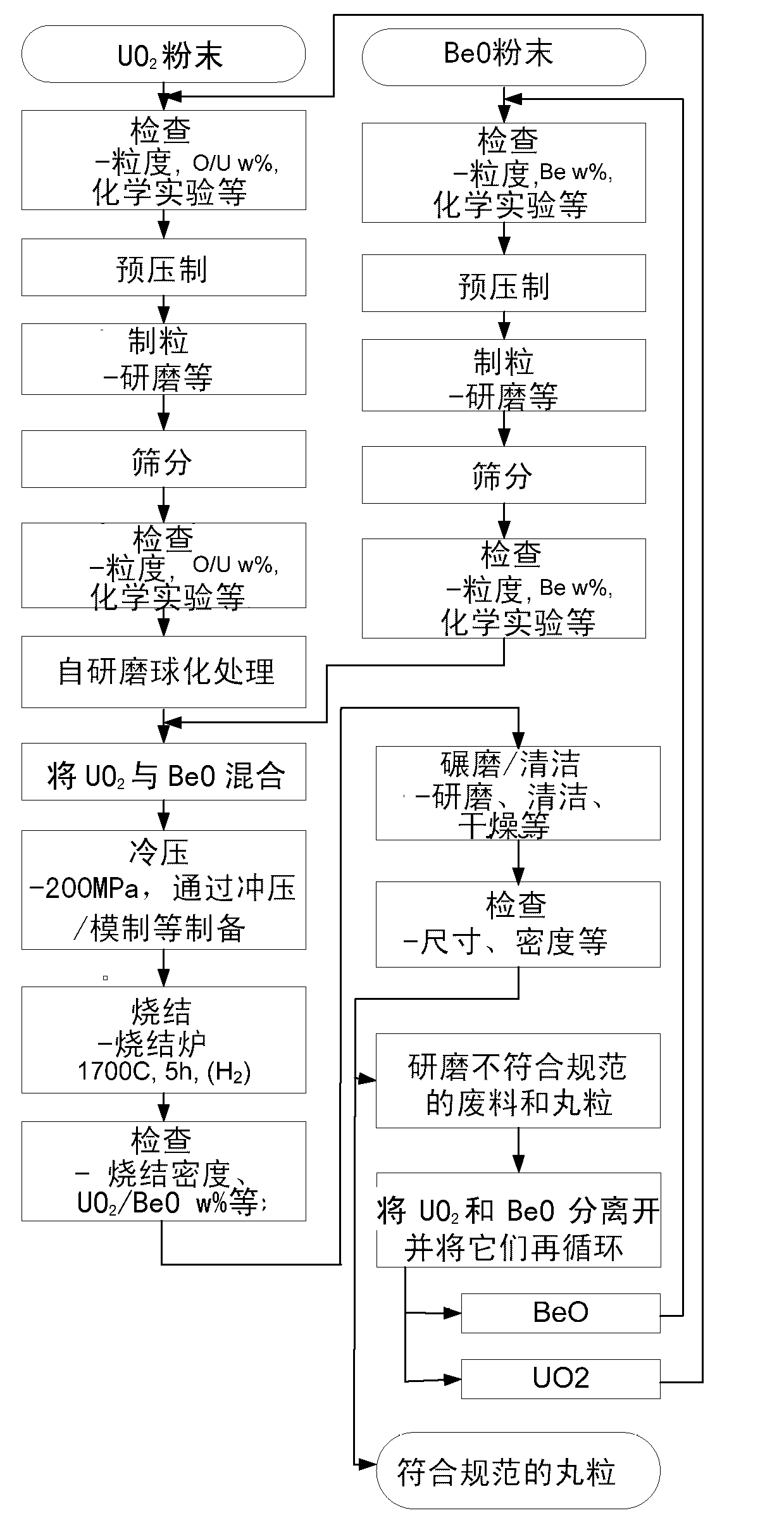

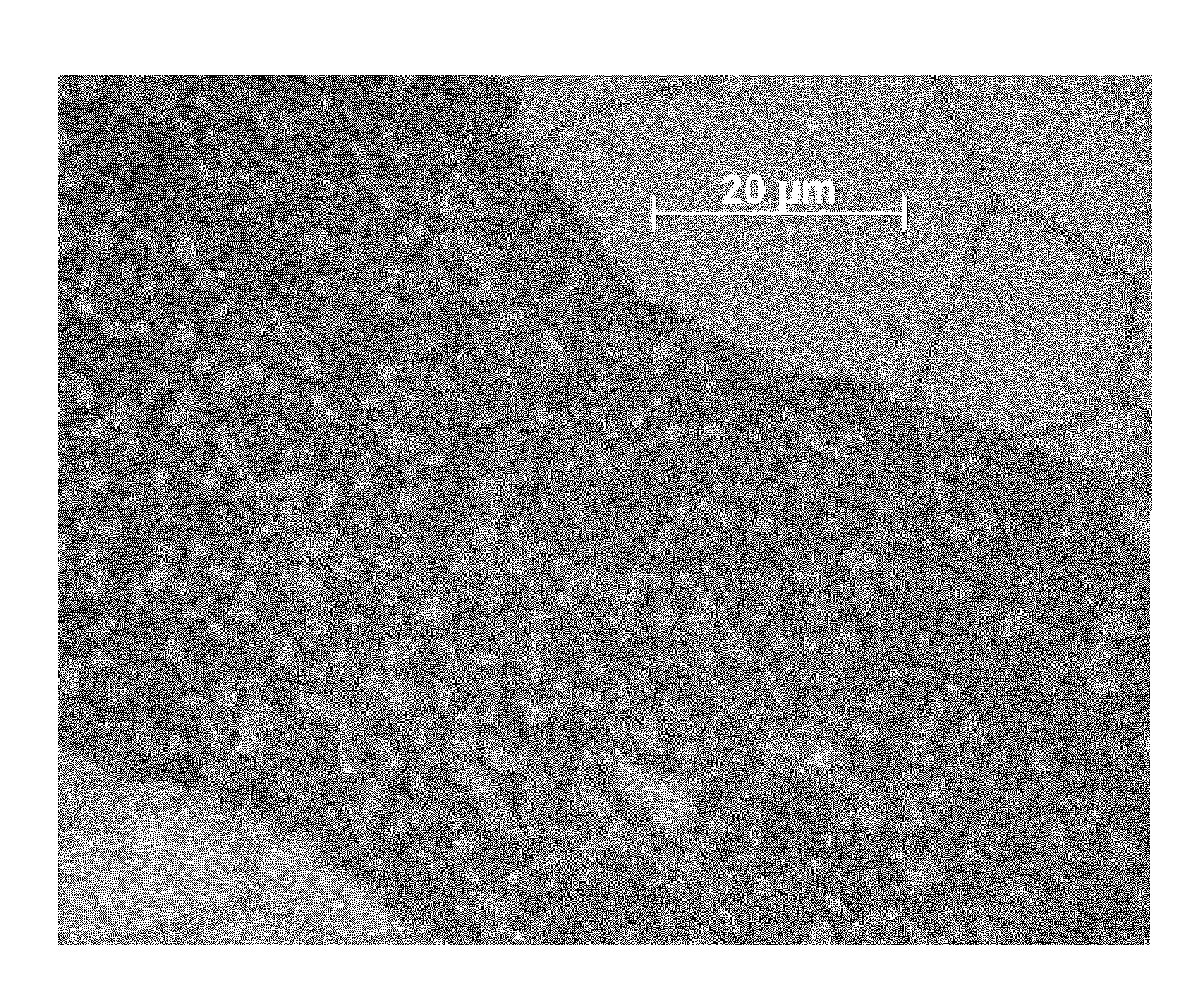

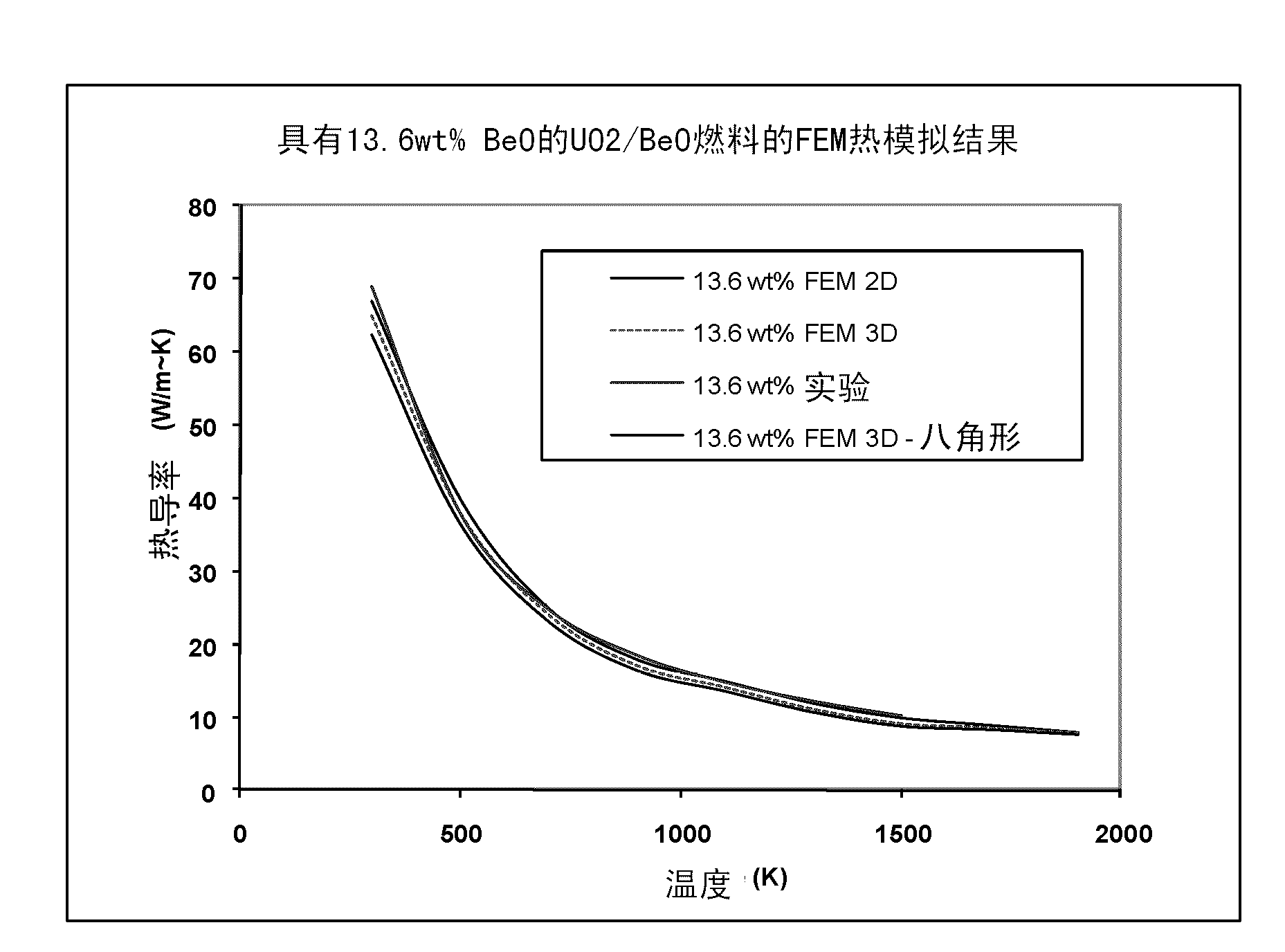

[0023] The present invention provides an advance in the science and technology of preparing ceramic nuclear fuels with higher thermal conductivity. As will be discussed below, the present invention includes methods for preparing heterogeneous ceramic-ceramic nuclear fuels especially based on UO 2 A nuclear fuel process where BeO is the added ceramic phase, which increases the effective thermal conductivity of the nuclear fuel. A preferred aspect of the invention uses a three-dimensional (3-D) finite element method (FEM) to thermally model the fuel, by which thermal conductivity can be predicted as a guide for subsequent process optimization. Other preferred aspects of the invention include the actual production process for producing ceramic-ceramic fuel pellets by which the microstructure of the fuel produced has a controlled particle size distribution and a controlled volume fraction for the different ceramic phases. The pressing and sintering parameters used in the preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com